One of the most frequent questions from my undercar customers is in regards to the availability of “greasable” chassis parts. Sealed-for-life components are very common at the OEM level, but many technicians have a definite preference for aftermarket greasable components. This poses the question: If greasable suspension joints are so popular, why don’t many modern suspensions have grease fittings anymore?

One of the most frequent questions from my undercar customers is in regards to the availability of “greasable” chassis parts. Sealed-for-life components are very common at the OEM level, but many technicians have a definite preference for aftermarket greasable components. This poses the question: If greasable suspension joints are so popular, why don’t many modern suspensions have grease fittings anymore?

The grease fitting is going the way of the 3,000-mile oil change interval, and for many of the same reasons. For years, the oil change interval (OCI) has been a basic reference point for many other maintenance services, including chassis lubrication. Mileage-based service recommendations are often multiples of the OCI, providing vehicle owners (and service technicians) with a convenient and logical maintenance schedule. For the OEMs, extended service intervals translate into a reduction in periodic maintenance costs, as well as the appearance of reliability and longevity. As the average OCI increases and these other services need to be performed less frequently, our opportunity for periodic inspection declines. This may be a contributing factor in our perception that we see more outright failures of components. We aren’t seeing the vehicles as often, so more can go wrong between visits.

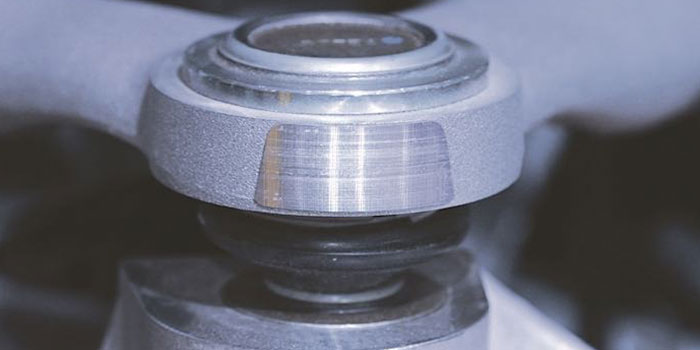

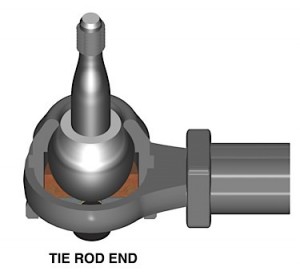

Material costs make sealed-for-life suspension components an attractive option for OEM engineers, as well as the folks in their accounting offices. The sealed joint relies heavily on polymer (plastic) technology, decreasing raw material costs when compared to metal-on-metal designs. A highly polished steel ball stud rotates within an injection-molded polymer socket, resulting in a low-friction joint capable of smooth articulation under moderate loads. This design is adequate for many automobiles and some light trucks, especially when designing components like sway bar links and tie rod ends. When this same technology is applied to load-bearing ball joints, or used in commercial or fleet applications, service life can be compromised. Premature failures, like those of the first-generation Chevy Trailblazer or Ford Transit Connect, contribute to a negative perception of the sealed joint design.

Material costs make sealed-for-life suspension components an attractive option for OEM engineers, as well as the folks in their accounting offices. The sealed joint relies heavily on polymer (plastic) technology, decreasing raw material costs when compared to metal-on-metal designs. A highly polished steel ball stud rotates within an injection-molded polymer socket, resulting in a low-friction joint capable of smooth articulation under moderate loads. This design is adequate for many automobiles and some light trucks, especially when designing components like sway bar links and tie rod ends. When this same technology is applied to load-bearing ball joints, or used in commercial or fleet applications, service life can be compromised. Premature failures, like those of the first-generation Chevy Trailblazer or Ford Transit Connect, contribute to a negative perception of the sealed joint design.

In some applications, tight clearances would make it nearly impossible to gain access to a Zerk fitting. With their sealed design, low-friction joints allow engineers to create compact assemblies, offer a reasonably long service life without periodic maintenance, and cut production costs. In applications like these, even premium aftermarket manufacturers rely on sealed joints, choosing to beef up the internal components rather than duplicating a failure-prone OE design.

A common complaint among techs is that the OEMs are just “being cheap” by eliminating a ten-cent grease fitting. Well, consider that an average front-wheel-drive car has at least 10 possible grease-fitting locations (one each in the lower ball joints and outer tie rod ends, two each in the sway bar links). At ten cents each, there are about a dollar’s worth per vehicle. Extended out over a production run of a million vehicles, these savings can be considerable. Also, many joints on multi-link suspensions are too accessible.

A common complaint among techs is that the OEMs are just “being cheap” by eliminating a ten-cent grease fitting. Well, consider that an average front-wheel-drive car has at least 10 possible grease-fitting locations (one each in the lower ball joints and outer tie rod ends, two each in the sway bar links). At ten cents each, there are about a dollar’s worth per vehicle. Extended out over a production run of a million vehicles, these savings can be considerable. Also, many joints on multi-link suspensions are too accessible.

In addition to the assembly-line savings, fewer grease fittings means a more streamlined dealership LOF checklist, saving a few minutes of labor on a loss-leading service, especially on vehicles under warranty.

Many premium aftermarket brands feature serviceable metal-on-metal designs with grooves or channels in the ball and socket assemblies to help distribute grease throughout the joint. These joints often target vehicles that have known problems. They are also often found in fleets. These joints can extend the life of the joint and reduce downtime due to repairs.

Attempting to drill and tap an OE-style joint to accept a Zerk fitting is often counterproductive. This introduces a pathway for contaminants into a sealed environment and enhances the possibility of damaging the joint itself. Debris from the drilling and tapping process may enter the joint. Also, lubricating the joint will destroy the boot due to the pressure of the grease gun.

The tight tolerances inside the sealed joint do not provide much room for additional lubricant. Forcing grease into the joint may damage the existing sealing surfaces, leading to accelerated loss of lubricant. Some manufacturers will use teflon and other surface treatments to reduce friction and heat.

Some technicians and vehicle owners prefer the “hands-on” benefits of periodically inspecting and lubricating a serviceable joint. When possible, replacement of the OE-style sealed joint with a premium greasable joint is more cost-effective in terms of longevity, serviceability and performance than trying to re-engineer the existing design.

Courtesy Brake & Front End.