Brake shims are not cosmetic or designed for adjusting spacing and distance between the friction material and the rotor. Instead, shims provide multifunction noise control as a component that’s attached to the friction pad backing plate.

A quality brake shim can prevent brake noise during the entire life of the brake job and will not dry out or be displaced over time like some lubricants or pastes. But, remember, a shim cannot do its job if it remains in the box.

The first thing to remember is that all brakes make noise — whether it’s the brakes on a Rolls Royce or a Toyota. It is just the noise has been “tuned” outside of the range of human hearing or minimized so it does not reach the driver.

When the pads press into the rotors, vibrations are made which then become noise. Humans have a limited range of sounds they can hear. If the noise is out of the range of human ears, there will not be a noise complaint. It is when these vibrations transfer into the caliper and knuckle, where they are lowered to human hearing ranges, that the driver notices a noise.

When the friction material makes contact with the rotor, the coupling causes the brake pad and rotor to oscillate and vibrate. In engineering terms, this is called “force coupled excitation,” which means that the components are locked as a combined system that will vibrate at the system’s natural frequency in combined modes of vibration. The driver hears these vibrations as noise. This is “ground zero” for brake noise.

When the friction material makes contact with the rotor, the coupling causes the brake pad and rotor to oscillate and vibrate. In engineering terms, this is called “force coupled excitation,” which means that the components are locked as a combined system that will vibrate at the system’s natural frequency in combined modes of vibration. The driver hears these vibrations as noise. This is “ground zero” for brake noise.

Brake shims prevent and reduce the transmission and amplitude of vibrational forces that cause excitation of the caliper, pad assembly and attached structure. They prevent vibrations that start at the pad and rotor from being transferred into the caliper and knuckle.

This is accomplished by viscoelastic damping material inherent within the layering construction of the shim and method of bonding to the pad assembly.

High-quality brake shims are frequency and temperature engineered multi-layered products using varying grades of metal, viscoelastic polymers/bonding materials, elastomeric rubbers and fiberglass.

Some brake pads now include an outer layer of pressure-sensitive adhesive.

High-quality brake shims usually start with a high-quality metal or fibrous material. The shim manufacturer will select a grade of material with the right hardness, thickness and dampening properties. The elastomeric materials can be applied to the steel in a controlled process that ensures the correct depth. These materials are then vulcanized to the metal to ensure that they will endure the harsh environment of the braking system.

Engineers “tune” these layers to give the best NVH qualities for the specific brake system noise fingerprint or signature. In some cases, the brake system will need just a steel plate shim. For other brake systems, the shim might be a four-layer sandwich that floats, insulates and lubricates.

Regardless of the design, if the shim is not making contact with the brake pad, it will not do its job. This is because the pad/caliper assembly undergoes complex and dynamic vibrational deformations due to the superposition of the combined system’s natural frequency mode shapes that must be controlled by an adequately attached insulator.

Lubricants and Pastes on Shims

When a caliper finger is lubricated at the point it touches the brake pad, the lubricant creates a boundary layer that separates the vibration of the brake pad from exciting the caliper finger and the caliper. This is one approach to solving NVH problems that can have its limitations.

Lubricants and pastes do not dampen forces by adding extra mass to the brake pad. Also, lubricants can’t fill in pitting on brake slides. Additionally, lubricants do not insulate against vibration and are ineffective for some frequencies.

Staying power is what special-purpose brake lubricants have over other lubricants. Specially formulated, high-temperature brake grease can withstand the heat, and also not harm rubber seals or plastic bushings.

Why Does This Matter to You?

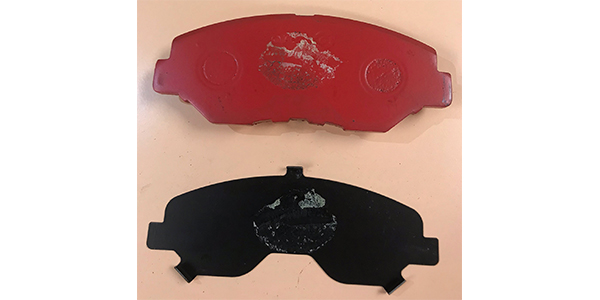

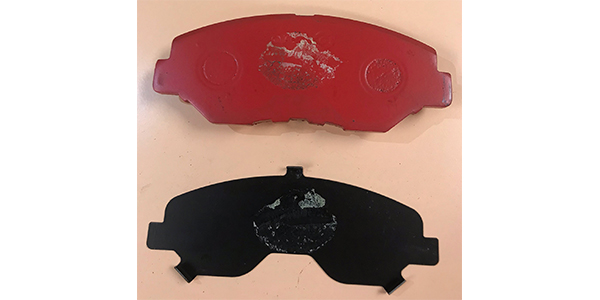

The old saying of, “don’t judge a book by its cover” applies to brake pads and shims. The design of the shim, backing plate and the shape of the friction material are dependent on the caliper, suspension and the formulation of the friction material.

There is no way to say one brake pad shim is better than the other regarding noise or even cost, unless you have a testing laboratory that can test the entire vehicle. The design of the shim and brake pad is the product of the vehicle. Some brake pads and shims look great coming out of the box, but the engineering might be ill suited to the application.

The final judge of the quality of a shim and brake pad is the technician. Take the time to go on a test drive after the pads are installed on the vehicle. Just pumping up the pedal and backing it out of the bay is no way to ensure that there will be no problems with the brakes when the customer picks up his or her vehicle.

Article courtesy Brake & Front End.