Almost anywhere in the country, it’s common for car lovers to meet in random groups with their rides, hang out, and share stories, ideas and dreams.

A quick walk around some of these classic rides and you will understand what it was like to be around them all the time. It’s that strong fuel smell that reminds me of a day when fuel tanks were vented to the atmosphere. I don’t know how more cars didn’t catch on fire back then.

We don’t have that obvious smell in vehicles anymore, as they’ve had some sort of an evaporative fuel capture system for many years. I remember that the early 1980s cars had a charcoal canister and they were purged through a temperature-controlled vacuum switch that, once opened, drew vapors from the canister. There were no sensors and no monitoring. It usually worked pretty well, that is, until a valve failed and the engine started to draw enough vacuum in the vent system to collapse a fuel tank, or worse, draw raw fuel into the engine causing an overly rich condition.

We’ve come a very long way in reducing evap emissions from computer monitoring, to slosh control, to non-return fuel systems. It makes sense to stop picking up that engine heat and bringing it to fuel tank, causing fuel to expand.

Fast Forward to Today

Laws change and technology advances. Now we can actually “monitor” the evaporative emissions system. There are pressure sensors, electric vacuum switches, and computer-controlled activation and monitoring. Anyone who works on an Evaporative Emissions code knows that there are as many possible causes, as there are ways to determine the failure. Proper equipment and test procedures are critical to prevent comebacks and a frustrated customer.

Recently, the shop had a 2002 Lexus SC 430 in for a check engine light with evap codes P0440 – evap malfunction; P0441 – evap incorrect purge flow; and P0446 – evap vent control malfunction. When I taught engine performance at the community college, I had four rules for automotive repair:

1. Check the basics

2. Check the basics

3. Check the basics

4. See rule No.1

In this case, it proved true (and beneficial) again. The first order of business when we have multiple codes for the same system (or multiple codes in general) is to determine the common factors.

Our research of the code numbers revealed that all of the shared vacuum hoses or a defective fuel tank cap are the most likely trouble areas. Now, a basic inspection is in order, as well as checking all of the shared items, starting again with the basics.

First, check the fuel cap and seal (see Photo 1). I know Captain Obvious, but the one time it’s not checked is the time the seal will be damaged or missing.

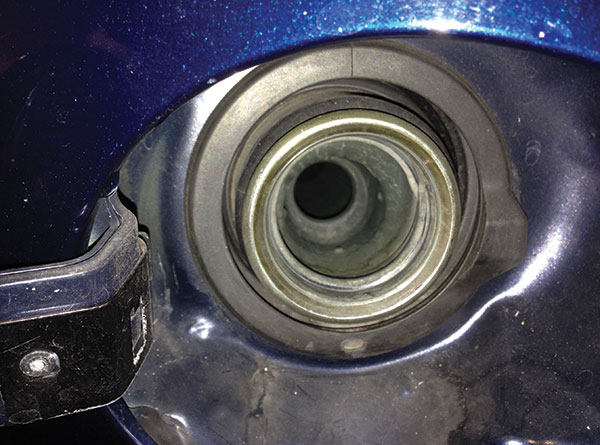

Next is the filler neck, and this one was OK (see Photo 2). The shop has seen many cars coming in with a slight bend in the neck that prevents a good seal. I suspect the reason for this is busy drivers getting gas and forgetting the nozzle is still in the tank.

Next is an underhood inspection. We wanted to check the service test port for the system, and we discovered a disconnected hose (see Photo 3).

I suppose the interview question at writeup needed to be clearer. We often ask if anyone looked at the car for this problem (the answer is no). I guess we will need to start asking, “Did the problem start after a recent service visit?” That may have indicated a possible workmanship issue at a prior shop.

We reconnected the hose and performed several drive cycles to reset the Evap monitor, and all was good.

The PCM looks for pressure in the charcoal canister and fuel tank to drop or increase beyond the specified limit during the system self-test. Be prepared to test other components on these cars, if needed.

There are many hoses, lines and components that are unique to Lexus (see Photo 4, undercar driveline indicated by top arrow and exhaust indicated by bottom arrow). One in particular is only accessible by dropping the fuel tank. If you need to check the overfill check valve, be prepared to drop the tank. And when you do, also be prepared to drop the exhaust and driveline. So be sure you’ve checked everything else first.

EPA Standards Looming

But wait, there’s more. There are new EPA standards that became voluntary in 2017, and will be mandatory by 2022. The EPA standards say this: “To control evaporative emissions, more stringent standards will require covered vehicles to have essentially zero fuel vapor emissions in use, including more stringent evaporative emissions standards, new test procedures, and a new fuel/evaporative system leak standard.

“Tier 3 also includes refueling emissions standards for complete heavy-duty gasoline vehicles (HDGVs) over 10,000 lbs. GVWR. There are phase-in flexibilities, as well as credit and allowance programs. The standards, harmonized with California’s zero evaporative emissions standards, are designed to essentially eliminate fuel vapor-related evaporative emissions. The Tier 3 evaporative emissions standards will be phased in over a period of six MYs, 2017-2022.”

So, you can be sure it will be challenging to continue to test and repair these new systems. There are many new standards and they’re not only for passenger cars.

The new standards continue with: “There is a new testing requirement referred to as the bleed emissions test procedure. Manufacturers will be required to measure diurnal emissions over the 2-day diurnal test procedure from just the fuel tank and the evaporative emissions canister, and comply with a 0.020 g/test standard for all LDVs, LDTs and MDPVs without averaging. The canister bleed emissions standard test will apply only to low-altitude testing conditions, but there is proportional control at higher altitudes.”

To learn more details about the EPA standards, visit: http://nepis.epa.gov/Exe/ZyPDF.cgi/P100GD35.PDF?Dockey=P100GD35.PDF.

So, what does all of this mean? A proper diagnostics approach will not only simplify your evap emissions-related jobs, but will move you one step closer to meeting the upcoming EPA standards for this type of work. If we all do it the same way, we can get consistent results, quicker turnaround and, most important, a happy customer with a properly repaired car.

Article adapted from Import Car.