10 Tips For Serpentine Belt System Inspection And Service

Like a tire, the friction between the belt and pulleys wears away at the belt, usually on the tops and walls of the ribs.

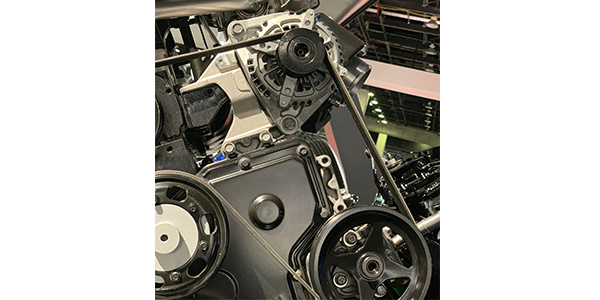

Top 10 Timing Belt Tips

Here are the Top 10 timing belt job tips that can make your next job just a little easier.

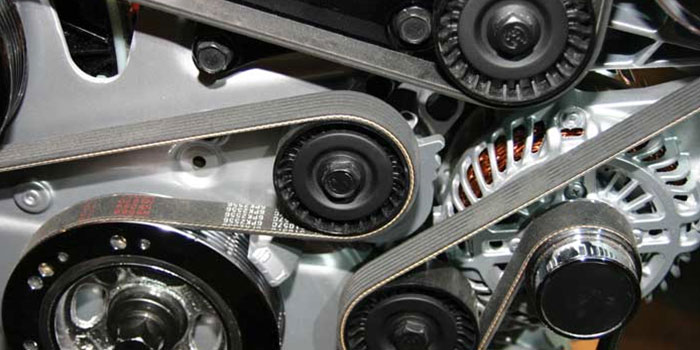

Serpentine Belt Drive Alignment And Wear

Belt misalignment can be caused by any of the accessory pulleys or might be the result of improper belt installation.

Component Connection: Belt Wear Diagnostics

Serpentine belts may last up to 100,000 miles before they need to be replaced. If a belt fails sooner, you need to be a detective and investigate why it failed.

Serpentine Belt Inspection Checklist

You might have only one chance to sell a customer a new serpentine belt. With belts lasting roughly 90,000 miles, proper inspection at the time of failure is critical not only for selling the belt, but also for ensuring add-on sales and better customer satisfaction.

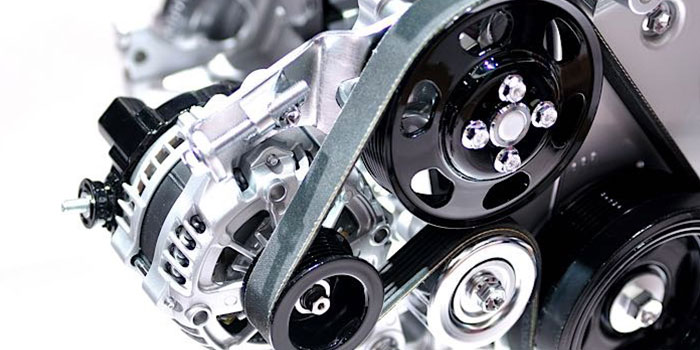

Serpentine Belts: Inspecting And Replacing

A technician’s senses are often the most valuable tools in helping assess what repair or replacement parts are needed on a given job. Specifically, the ability to visually inspect parts for wear and tear to know when it’s time for replacement is the calling card of any successful technician. But when it comes to modern serpentine belts, you can’t trust your eyes anymore to tell you when it’s time for a new belt.

Diagnosing Belt Wear

The original equipment belts on late-model vehicles are made of synthetic materials and are far more heat-resistant and wear-resistant than older materials. These innovations mean serpentine belts may last up to 100,000 miles before they need to be replaced. If a belt fails sooner, you need to be a detective and investigate why it failed.

Stretch Belts: Inspection And Installation

Why stretch belts? For the more than two decades, automakers have consolidated accessory drive components onto one belt. It worked for most engines, but for some it presented issues with noise and vibration as the A/C compressor engaged.

Tips For Serpentine Belt System Inspection & Service

Like a tire, the friction between the belt and pulleys wears away at the belt, usually on the tops and walls of the ribs. Eventually the grooves of the pulleys will bottom out on the grooves of the belt, and then the belt will start to slip.

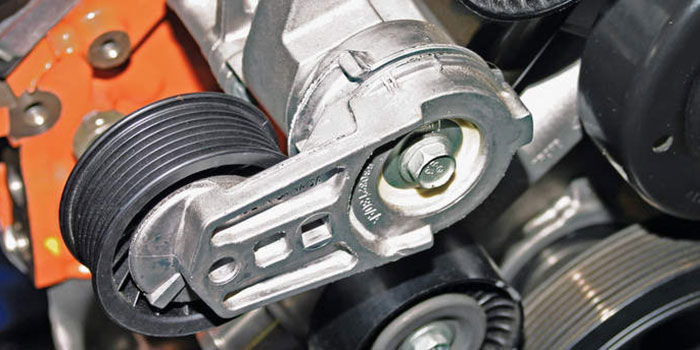

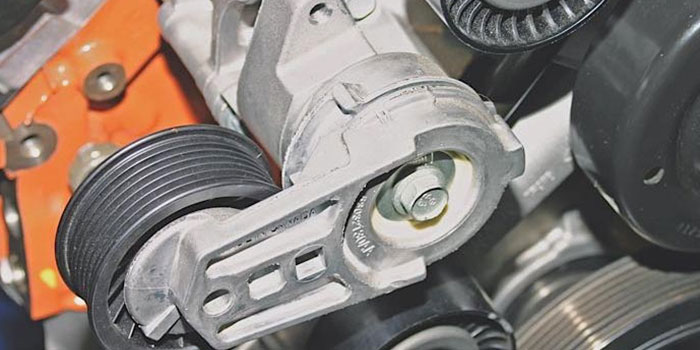

Automatic Belt Tensioners Are More Than Just Springs

A worn automatic belt tensioner has consequences beyond a loose belt. When an automatic belt tensioner wears down, the belt and attached accessories will start to take an extra pounding because the tensioner can no longer dampen the power pulses of the crankshaft. The effect on these components is similar to when a car has bad shocks that slowly destroy the suspension.