Tool Rules: Time to Look into Special Timing Belt/Chain Tools

Many engines require special tools when changing a timing belt or chain. At the very least, you should have a belt tension gauge to make sure the tension on a timing belt is correct.

Web Exclusive: Gearing Up for Timing Belt and Chain Work

The best time for a timing belt or chain to be replaced is before it fails. Technical Editor Larry Carley discusses items to consider when timing belt or chain work arrives in your shop or school in this Web Exclusive article.

Under the Hood: Short on Time – Compact Engine Timing Belt Service

As a rule, General Motors uses timing chains rather than timing belts on most of its engines. Timing chains are long-lived and reliable, and do not have a recommended replacement interval. But, not so with timing belts. One GM engine that does use a rubber timing belt is the 1.6L E-TECH II engine in the 2004 and up Chevrolet Aveo. We take a look at timing belt procedures for this and similar compact engines.

Practical Tips for Timing Belts

Changing the belt correctly – for 100% drive function.

Understanding Engine Timing- Chains, Gears and Belts

Engine timing is critical for overall performance.

Understanding Belt-In-Oil Timing Systems

Oil contamination of the belt drive has been a death sentence, due to the rubber and fiber construction of the belt.

VIDEO: Timing And Drive Belt Idler Pulley Bearing Loads

Both timing and drive belt systems use idler pulleys to tension and control the movement of the belt. If components on the timing or drive belt system are misaligned, the loads on the bearings are changed. The change in the loading of the bearing can result in damage and failure of the belt system.

Belt-In-Oil Timing Drives

Since the adoption of timing belts by auto manufacturers began in the early 1970s, it has been pretty well beaten into our heads that oil and timing belts do not play well together.

Under the Hood: Gearing Up for Timing Chain and Belt Work

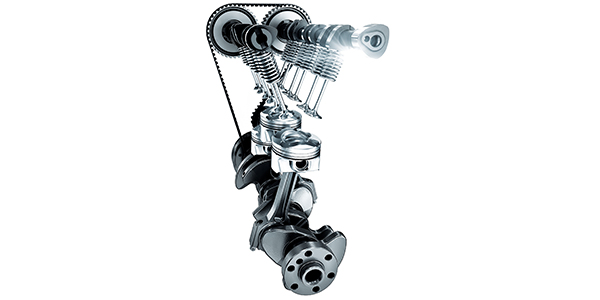

Timing belts and chains carry a heavy load. They have to turn the cam with enough force to overcome the resistance of all the valve springs. However, the main cause of belt wear is heat. As a belt wraps around and turns the sprockets, friction creates heat (this is in addition to the heat from the engine itself). Over time, this causes the rubber to lose flexibility, harden and crack.

Timing Components

By adopting a systematic approach and utilizing quality kits, the longevity and efficiency of the timing system can be maximized, ensuring a smoother-running engine. This video is sponsored by The Group Training Academy.