Like a houseful of teenagers, today’s high performance engines are hungry and thirsty. Whether running on the street or the strip, our ravenous appetite for speed means their ravenous appetites must continue to be fed.

Like a houseful of teenagers, today’s high performance engines are hungry and thirsty. Whether running on the street or the strip, our ravenous appetite for speed means their ravenous appetites must continue to be fed.

The induction system feeds the engine air and fuel. So to increase the torque and horsepower output of an engine, the induction system has to provide more air and fuel.

That usually means adding an aftermarket performance intake manifold with taller, larger and/or longer runners to increase air flow into the cylinder head ports, bolting on a larger carburetor, throttle body or multiple carburetors that can flow more cubic feet per minute (cfm) of air, or maybe boosting airflow with a turbocharger or supercharger, and/or using nitrous oxide to add even more power.

There are a lot of induction system options to consider. Which setup you choose to use will depend on the application (street performance, circle track, drag race, off-road or marine), any rules that may restrict the kinds of parts that can be used, and your customer’s budget. A customer might want you to build a 1,200 horsepower drag motor for his Camaro, but if he only has $8,000 to spend that’s not likely going to happen.

As the power potential of any engine goes up, so do the physical loads on the pistons, connecting rods, crankshaft and block. Stock parts can only handle so much extra power before things start to break.

Consequently, if you’re building an engine to make a lot of power and are making induction system modifications that can potentially produce upwards of 500 horsepower in a small block, or 600 horsepower in a big block, you’ll also have to upgrade the engine’s internals with stronger components such as forged pistons, steel connecting rods, a forged steel crankshaft and four bolt main caps.

Boost-Mobile

Boost-Mobile

To increase airflow in a naturally aspirated engine, an engine builder needs to use a camshaft with lots of lift and duration, replace the stock valves with larger valves and either port the stock heads or install aftermarket performance heads.

Increasing the engine’s displacement with bigger bores and/or a longer stroke crankshaft will also pull more air through the engine. But these are expensive modifications that require a lot of machining and new parts. Even with extensive modifications, a naturally aspirated engine can only flow so much air.

And as engine speed increases, volumetric efficiency drops off. That’s because the force that pushes air into the engine’s cylinders is limited to atmospheric pressure.

Since it’s easier to push air through a small hole than it is to suck air through a small hole, a forced induction system can increase airflow significantly and much more easily and affordably than modifying a naturally aspirated engine.

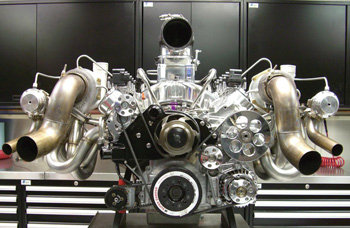

With a turbocharger or supercharger, it’s a different story. The induction system creates boost pressure to force more air into the engine. Turbocharging is one of the most effective ways to bolt on horsepower. You can bolt a turbo onto a relatively stock engine and produce as much power as you want by simply turning up the boost pressure.

For every pound of boost pressure, a turbo can add up to 35 or more horsepower depending on engine displacement.

Though turbos and blowers both use boost pressure to increase airflow and horsepower, they each have different breathing and performance characteristics.

Blowers are belt driven and require power input from the engine. Turbos, on the other hand, are driven by the exhaust so there is no power penalty. Positive displacement roots style blowers can produce boost at all engine speeds, and are good for low end torque and quick throttle response.

Turbos and centrifugal-style superchargers, by comparison, usually don’t produce much of a power increase under 2,500 rpm, but build boost pressure rapidly at higher engine speeds.

Turbo Tactic:

When building a budget turbo motor, you don’t need to spend a lot of money on CNC ported cylinder heads because a turbo can overcome the limitations of a stock head. Put most of your money into building a stronger bottom end to handle the power.

Though turbos can make a lot of power, they are less harsh on the engine and drivetrain compared to a blower or nitrous oxide. And, because the boost pressure ramps in as the turbo spools, there’s less shock on the drivetrain, which allows for more power to be put through these components with less risk of component failure.

This smoother application of power also keeps the tires hooked up. Turbos also create backpressure in the exhaust, which is beneficial because this residual pressure in the cylinders helps keep the pistons on the rods at high rpm.

The turbo isn’t the only necessary piece of equipment. A good turbo cam is also important. Turbo cams are specifically designed to deal with intake and exhaust pressure, while keeping them separated, so are very different than a naturally aspirated, NOS cam or a supercharger cam.

The turbo isn’t the only necessary piece of equipment. A good turbo cam is also important. Turbo cams are specifically designed to deal with intake and exhaust pressure, while keeping them separated, so are very different than a naturally aspirated, NOS cam or a supercharger cam.

All turbos have some lag between the time you step on the throttle and when the turbo actually reaches full boost. With one or more turbos mounted in the rear of the vehicle, the transition is slightly smoother and more controllable than the more violent hit of engine-mounted turbos. This lessens the risk of breaking the tires loose and losing control when it kicks in.

Since the exhaust temperature at the back of the car is up to 500° F cooler than at the exhaust manifold, rear turbo cooling isn’t a problem. Remote mounting also produces lower intake air temperatures (IAT), when combined with an intercooler, boosted IATs can be nearly ambient going back into the engine. STS Turbo has bolt-on rear-mount turbo kits and universal kits to fit just about every application.

Carbing Up

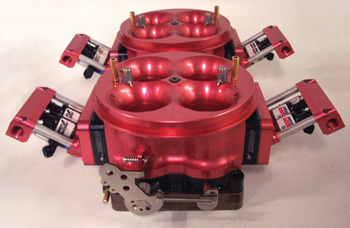

Carburetors have been the mainstay for performance engine builders for decades because they are relatively cheap compared to electronic or mechanical fuel injection systems, and they are simple, mechanical devices. A

carburetor is essentially a fuel metering device that uses suction (intake vacuum) to siphon fuel from a fuel bowl through metering jets into a venturi (the narrow part of the carburetor throat).

The fuel droplets mix with incoming air and are pulled past the throttle plates into the intake manifold.

Carburetors can be tuned by changing metering jets and emulsion tubes, adjusting the height of the float inside the fuel bowl(s), changing the linkage or cam that works the accelerator pump, and adjusting the idle mixture and idle speed screws. But carburetors can also be temperamental.

Carburetors can be tuned by changing metering jets and emulsion tubes, adjusting the height of the float inside the fuel bowl(s), changing the linkage or cam that works the accelerator pump, and adjusting the idle mixture and idle speed screws. But carburetors can also be temperamental.

Changes in air temperature and humidity can upset the air/fuel ratio. Too little or too much fuel enrichment when you mash down the gas pedal can cause the engine to bog. Because of this, racers are constantly fiddling with the adjustments at the race track to achieve the best performance.

Aftermarket performance carburetors are available from a variety of companies. You can buy a new carburetor, a factory remanufactured carburetor or a custom modified carburetor for the engine you are building. For a street motor, you’ll probably want a carb with an automatic choke for reliable cold starting and idle during warm-up.

The carb should also have all the required vacuum hookups for the PCV system, EGR, power brake booster and other vacuum accessories, plus ported vacuum for the vacuum advance on the distributor (if used). Vacuum secondaries on a four barrel will also provide much better driveability on the street than mechanical secondaries.

Avoid “over-carbing” a street performance engine. For low end torque and good throttle response, the maximum airflow rating of the carburetor should not exceed the maximum airflow potential of the engine at the engine’s maximum rpm by more than about 10 to 15%. A 720 cfm carburetor is a good match for a 350 small block Chevy.

On a race motor, you can forget the choke and vacuum hookups. Mechanical secondaries are also the better option here. If the engine is being built to make high rpm power, you can install a much larger carburetor to maximize high rpm airflow.

Ideally, you should choose the carburetor that goes on your engine and tune it yourself rather than leaving that step to the customer.

You can put together the greatest engine in the world, but if somebody screws up the carburetor, it can destroy the engine. The biggest danger is running the fuel mixture too lean, as that can quickly lead to detonation, preignition and burned pistons.

Tuning the carburetor and engine on a dyno while monitoring the exhaust gas temperature and composition will assure you that you have the right fuel mixture at all engine speeds and loads.

A number of aftermarket companies offer blue printed and modified carburetors, as well as purpose-built racing carburetors made of lightweight castings and billet aluminum components. One carburetor manufacturer has a patented booster and metering block design that creates smaller fuel droplets for better fuel atomization.

The stronger booster signal allows the fuel droplets to be about 50 times smaller than those you get with a

conventional carburetor — giving the driver more power to win races. It also means the carburetor is less sensitive to changes in temperature and elevation, so you don’t have to change jets all the time.

Another company said its line of performance racing carburetors have a reshaped venturi entrance that enhances airflow, a lengthened venturi section that improves throttle response, and shielded air bleeds that eliminate air turbulence for smoother airflow and better fuel atomization.

Going Electric

Aftermarket EFI systems have been around since the 1980s. EFI replaced carburetors on late model vehicles in the mid-1980s to meet new emission and fuel economy requirements. EFI provides easier cold starting, lower emissions and better fuel economy that most carburetors, which makes it a good choice for street applications.

With multiport EFI systems that have a separate fuel injector for each cylinder, better cylinder-to-cylinder fuel distribution is also a plus. Only air flows through the intake manifold, so there is no fuel separation to worry about. With a carburetor or throttle body injection, the intake manifold is wet. The air and fuel are mixed together as they enter the manifold. Fuel droplets are heavier than air, and may separate as the fuel mixture follows the twists and turns of the intake manifold.

This can result in uneven fuel mixing and reduced power at higher engine speeds where intake velocities are high.

Another advantage EFI has over a mechanical carburetor is that EFI is “self-tuning.” By using an oxygen sensor in the exhaust to monitor the air/fuel mixture, the fuel mixture can be constantly adjusted on the go to maintain an ideal fuel mixture.

That means no fiddling with adjustment screws or changing jets to compensate for changes in temperature or altitude. The fuel curve can also be modified electronically by programming the control module to deliver any fuel ratio you want at any speed or load.

The downside of EFI is that it’s expensive – and a little too complicated for some people who are used to carburetors. An aftermarket multiport EFI system can cost $3,000 and up, which is a lot more than a good performance carburetor and manifold.

So for those who want a more affordable option, a number of companies are now offering bolt-on throttle body injection (TBI) systems that can be installed on virtually any engine that has a four barrel carburetor intake manifold.

Today’s EFI kits allow for a simple bolt-on conversion, and usually include everything needed to replace a four-barrel carburetor on a typical street performance engine. A good kit may include a throttle body with injectors, control unit, wide band oxygen sensor, wiring, fuel pressure regulator, fuel return line, fittings and electric fuel pump.

Installing them can be as simple as replacing the carburetor with the throttle body unit. Drill a hole in the exhaust collector or manifold for the O2 sensor, make a wiring connection or pickup up a tach signal from the existing ignition system, and you are ready to start the engine.

A module can be preprogrammed to build its own fuel map based on fuel mixture corrections via the O2 sensor, so no programming with a laptop is needed.

Taking Intakes Into Consideration

The type of intake manifold that goes on an engine also plays a huge role in how the engine breathes, and the amount of torque and horsepower it makes. Most aftermarket intake manifolds are cast aluminum for light weight, though many custom racing manifolds are welded steel or aluminum. We’ve also seen some plastic aftermarket intake manifolds, which are very light and capable of running fairly cool due to the fact that plastic does not conduct heat well.

A cool intake charge is a more dense, powerful charge, so some aftermarket performance intake manifolds feature an air passageway under the runners and plenum to help isolate the manifold from engine heat. Street manifolds generally include a heat riser passageway to assist fuel vaporization, which is necessary following a cold start. But most race manifolds have no such duct and block off the heat riser ports.

Street manifolds also have emission hookups for the EGR and PCV systems (as required), while race manifolds have no such connections.

Dual plane (also called 180 degree) manifolds split the plenum into two halves, and feed each side of a V8 engine separately. This provides better throttle response and low-end torque for everyday driveability. A low-rise manifold may be required if hood clearance is limited, while a high-rise manifold with taller, longer runners is generally good for a little more power.

Most race manifolds, on the other hand, have an open or single plane plenum (also called 360 degree), which typically produces more airflow and horsepower at higher engine speeds.

Replacing a stock manifold with an aftermarket manifold usually requires no other engine modifications. If you’re using aftermarket heads that have a different face angle, port configuration or port height than the stock heads, however, you’ll have to use an intake manifold that matches the heads. This may limit your choice depending on what’s available for a particular head.

Regardless of what kind of intake manifold/cylinder head combination you use, matching the ports in the manifold with the head is important to optimize airflow. You don’t want any misalignment, sharp edges or abrupt changes in port diameter to disrupt airflow.

Opening a Can of Whoop ***

Opening a Can of Whoop ***

We’ll wrap up this article on induction systems with a few words about nitrous oxide. Power in a bottle is an easy add-on that can boost any engine’s output up to 200 hp or more depending on how big a shot of nitrous you’re giving the engine.

Nitrous creates a lot of extra heat and pressure in the cylinders, so the pistons, rods and crank should be stout enough to handle the increased load. Also, you have to make sure there’s enough fuel delivery so the fuel mixture doesn’t lean out and send the engine into detonation.

Nitrous probably provides the most bang for the buck of any induction system add-on. For a relatively small investment, you can install a nitrous system on almost any engine. That’s far cheaper horsepower than almost any other modification you can make. But there are limits.

Many types of racing don’t allow nitrous. Some states also prohibit the use of nitrous on the street. And if you go too crazy with the nitrous, you can blow up the engine and scatter parts everywhere!

Experts caution you to be sure that the additional nitrous isn’t TOO much for the engine. Plus, they encourage you and your customers to pay attention to what’s included in the nitrous install. If you’re installing a kit on an engine, you’ll want to be sure you charge for all the necessary components. There’s a reason, say industry suppliers that some sets are called “kits” and some are called “system.”

Experts caution you to be sure that the additional nitrous isn’t TOO much for the engine. Plus, they encourage you and your customers to pay attention to what’s included in the nitrous install. If you’re installing a kit on an engine, you’ll want to be sure you charge for all the necessary components. There’s a reason, say industry suppliers that some sets are called “kits” and some are called “system.”