By Gene Markel

Potholes and road splash take the biggest toll on suspension parts, especially on the vehicle’s right (curb) side. Shocks, struts and ball joints receive the most attention for replacement. But, unless the chassis anti-roll bar — also called the sway bar or stabilizer — is making noise, it tends to be missed when the suspension is serviced.

Potholes and road splash take the biggest toll on suspension parts, especially on the vehicle’s right (curb) side. Shocks, struts and ball joints receive the most attention for replacement. But, unless the chassis anti-roll bar — also called the sway bar or stabilizer — is making noise, it tends to be missed when the suspension is serviced.

This is also true for upper strut bearings and control arm bushings. With so many minivans, crossovers, SUVs, vans and trucks on the road, special attention should be given to the chassis anti-roll bar on these vehicles as the anti-roll bar has a significant effect on a vehicle’s stability during a cornering maneuver as the center of mass on these vehicles is higher than on a passenger vehicle.

Rolling Along

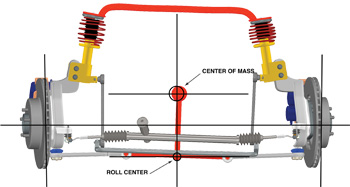

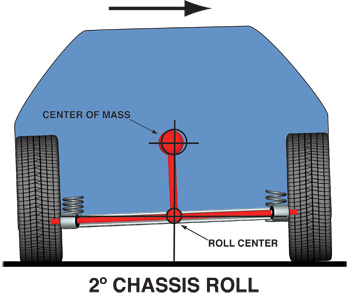

Chassis roll is determined by an axis running from the rear roll center to the front roll center of the vehicle. The axis forms a plane that determines the rotation of the chassis during a corner. The inclination of the plane and center of mass of a vehicle determine how much the chassis roll will occur during a corner.

The chassis anti-roll bar is a mechanical device made up of a formed metal bar that can be solid or hollow and connector links. The bar attaches to the chassis and then links connect it to the lower control arms or struts. The change in position of the control arms will cause the bar to lift the chassis on one side and pull it down on the other depending on the direction of the turn. (See Figure 1)

During a cornering maneuver, the entire weight distribution of the vehicle changes. In a right-hand corner, the majority of the weight is placed on the left front wheel. The right rear wheel carries the least amount of weight. If the vehicle is breaking in the corner, even more weight is shifted to the right front wheel.

Cornering or lateral acceleration causes the chassis to roll. The faster the corner, the more the chassis will tend to roll.

Rolling Performance

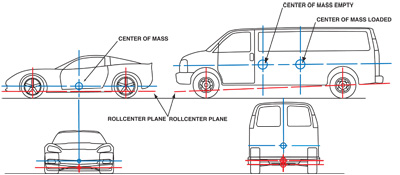

The extremes of vehicle construction can best demonstrate how the roll center and center of mass affects chassis roll. The Corvette is a performance vehicle designed for high speed cornering. It has a roll center that is parallel to and almost at ground level. Its center of mass is very close to the roll center and is located in the center of the vehicle. This produces an almost neutral position during high-speed corners. The ground clearance of the Corvette is minimal, as it is to be driven on maintained paved surfaces.

The van is a utility vehicle designed to transport passengers and cargo and its ground clearance is much greater. Its roll center axis is on an incline as the roll center of the rear axle is higher than the control arms of the independent front suspension. Its center of mass is toward the front of the vehicle and can change based on how the vehicle is loaded. The chassis control components of the van will receive more stress under normal service than those in the Corvette. (See Figure 2.)

Front-Wheel-Driven Chassis

While the Corvette and van are both rear-wheel-drive vehicles, most of the passenger vehicles on the road today are front-wheel drive (FWD). Chassis roll for FWD vehicles is a combination of those for the Corvette and van. The roll center for the FWD vehicle is the same as the Corvette, as it is parallel to the ground, and its center of mass is like the van in that it is biased toward the front of the vehicle. (See Figure 3.)

The rear suspension of a front-wheel-drive vehicle can range from a fully independent suspension to a beam-type axle.

The independent suspension can be a trailing arm, strut or a double wishbone type, all utilizing an anti-roll bar.

The twist beam axle is the most common type used on a great variety of front-wheel-drive vehicles ranging from compact to mid-size. It uses the beam as an anti-roll bar when it is placed at the trailing arm pivot points. The mounting bushings are mounted at an angle toward the center of the vehicle. When the vehicle corners to the right, the left trailing arm moves toward a positive camber and caster and the right trailing arm moves toward a negative camber and caster. The clockwise rotation of the chassis on its roll center causes the beam to twist and move the trailing arms toward a zero camber and caster.

The bushings are key to the performance of the axle. The type of rubber and its hardness are key to the bushings. New bushings can produce a noise that can be described as a clapping sound when elastomer and hardness are changed from the original design.

The bushings are key to the performance of the axle. The type of rubber and its hardness are key to the bushings. New bushings can produce a noise that can be described as a clapping sound when elastomer and hardness are changed from the original design.

Putting a Durometer to the Test

The tires and bushings work with the shocks and struts to produce a given type of feel and ride for the vehicle. The bushings can either be natural or synthetic.

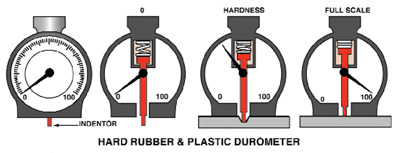

A durometer is a test instrument to measure the hardness of a material. The scale used to measure the hardness of plastics and rubber is based on the Shore Scale of zero to 100. A quality durometer for rubber and plastics testing can be purchased for under $400.

So why would you want to buy or use a durometer? It can be used to answer questions about tire performance, such as why did these tires wear out so fast or why did you replace those bushings? The softer the tread compound, the faster the tires wear or the bushings have softened when compared to new original equipment ones. (See Figure 4.)

Stability Control

Suspension and chassis service to this point have been straightforward processes of replacing worn or broken parts and then aligning the vehicle. This is changing with stability control systems that have been available since the mid-1990s on premium vehicles. In 2004, stability control was made standard on 15 passenger vans. In the 2008 model year, most models will have stability control standard or available. Stability control is mandated by law in 2012 for all vehicles.

Stability programs use the engine, chassis and brake electronics to control the directional stability based on input and output from these systems.

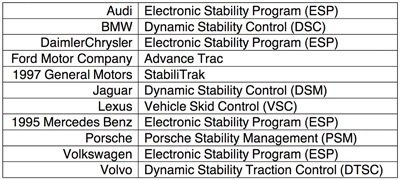

As you can see, the carmakers use different names for their control programs. (See Chart 1.)

The programs use the powertrain, brake and chassis controllers to process input from ABS wheel speed, vehicle speed, engine speed, throttle position, steering wheel position and a yaw sensor. (All stability control systems have a yaw sensor; This sensor measures the turning motion of the vehicle.)

The stability program can apply braking to an individual wheel and throttle control to correct the vehicle’s direction. The program has milliseconds to process the information and react to a change in vehicle direction indicating a loss of control. A combination of worn or damaged bushings, strut bearings or control arms could cause the program to display a warning light on the instrument panel or “Stability Alert” on the driver information center under normal cornering maneuvers on dry pavement.

The driver may not sense the change indicated by the yaw sensor and steering input resulting in the warning. If there is an obvious mechanical failure of a suspension part, such as a strut, that is an easy fix, but replacing the strut may not completely correct the problem. The control arms, strut bearings and anti-roll bar also may be contributing

factors. Alignment also factors into the response of the suspension to a steering input.

The photographs of the Corvette and the van show chassis roll under different conditions. The Corvette is approaching a high-speed corner and the van is making a defensive maneuver. The van is using stability control; The Corvette is not. (See Figure 5.)

Final Inspection

Suspension noise, vibration and harshness (NVH) are isolated from the chassis by the bushings. Every time a vehicle hits a bump or turns a corner, the bushings are stressed by an impact or a twisting motion. Bushings wear out when they lose their elasticity or shape. Struts wear out when they run out of oil.

When the vehicle is built, the shocks and struts valves are calibrated to new bushings. Car makers test a vehicle’s suspension for a given number of cycles that would represent X years and Y miles of normal driving. With preventive maintenance reduced to oil and filter changes at a quick oil change shop, the opportunity to inspect the suspension and underside of the vehicle are almost non-existent.

With road conditions and driving habits being the major factors in how long a suspension will last, a periodic inspection is a true safety concern.