Adapted from Gary Goms’ article in ImportCar.

Adapted from Gary Goms’ article in ImportCar.

While old-school cooling system service often focused on coolant leaks and overheating engines, let’s begin thinking “new-school” by looking at modern cooling systems through the eyes of the engine coolant temperature (ECT) sensor. Coolant temperature is important because torque converter clutch engagement, idle speed control, variable valve timing, engine cooling fan operation and various other powertrain functions depend upon the engine coolant quickly reaching full operating temperature. And, more important, ECT is often a primary component of the “enable criteria” needed to run diagnostic monitors and store diagnostic trouble codes (DTCs) and related freeze-frame data.

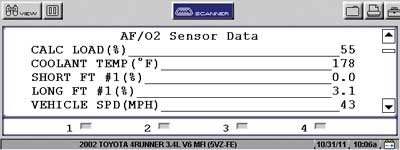

When designing a diagnostic test monitor, automotive engineers create a set of operating conditions (enable criteria) that must exist before the monitor will test the circuit in question. While enable criteria might include engine run time, specific system voltage levels, engine load and other operating parameters, most enable criteria will also include engine coolant temperatures. For example, a DTC for a failed oxygen sensor might not be stored if the engine fails to reach operating temperature. So, unless the ECT achieves full operating temperature within a specified length of time, diagnosing an intermittent or random no-code driveability or stalling complaint is nearly impossible. See Photo 1.

MECHANICAL FAILURES

Mechanical cooling system failures will usually store a P0128 DTC. To illustrate, let’s look at the enable criteria for a P0128 cooling system DTC on a 2008 Subaru Outback with the 2.5L 16-valve “H4” engine. According to service information, P0128 indicates that the thermostat is considered defective when the coolant temperature remains lower than its estimated or target temperature. The thermostat is considered good if the ECT reaches a minimum of 167º F. Note also that there’s no default strategy for a failed thermostat, which means that the engine and powertrain will react to the actual coolant temperature, rather than a default value substituted by the PCM. See Photo 2.

The “judgment value” or enable criteria for a P0128 includes a minimum 10.9 battery volts, an estimated intake air temperature of at least 19.4º F, a startup ECT of 131º F, an estimated or target ECT of 158º F, and an 86º F lower-than-estimated coolant temperature, all of which must occur at a vehicle speed of 18.6 or more mph.

With this application, a P0128 DTC requires two continuous drive cycles before it will illuminate the malfunction indicator light (MIL). The P0128 will automatically clear after 40 repeated drive cycles. The MIL itself will clear when a successful drive cycle is repeated three consecutive times. Obviously, there’s a lot of room here to create a no-code, intermittent driveability complaint. See Photo 3.

An accurately calibrated ambient air and ECT sensor is essential for the PCM to detect a major deviation from the target coolant temperature. Since enable criteria is very application-specific, the data parameters of Subaru’s P0128 DTC include intake air and startup, estimated and actual coolant temperatures. To function correctly, the ECT sensor and the thermostat’s wax pellet must contact liquid coolant. So, it’s always important to check for a low coolant level caused by an external coolant leak or by an internal coolant leak through a bad cylinder head gasket or cracked cylinder head.

Assuming the coolant level is correct, check for premature coolant flow by monitoring the upper radiator hose temperature. A luke-warm upper hose usually indicates a stuck-open thermostat. If the thermostat has stuck open, it’s entirely possible that a number of DTCs might appear after the thermostat is replaced, simply because ECT has restored the enable criteria for many sensor- and actuator-based DTCs.

On the flip side, if the thermostat sticks closed, the upper hose will remain much cooler than the engine block. If a sticking thermostat causes the engine to severely overheat, the engine control module (ECM) should store a P0217 DTC, indicating an overheat condition. And, during an overheat condition, many ECMs are programmed to help cool the engine by disabling alternate cylinders in the firing order. Since overheating is often a transient condition, it’s always important to check “history” codes for indications.

SENSOR CALIBRATION

As mentioned above, the ECM requires accurately calibrated intake air and ECT sensors to detect major deviations from the target coolant temperature. Many ECMs perform a simple rationalization test by comparing the indicated intake air and engine coolant sensor temperatures after the engine has cold-soaked overnight. The values should be nearly equal, with the intake air being slightly higher due to normal atmospheric warming.

While we’re at it, many older vehicles hard-wired a separate ECT sensor directly to the instrument cluster temperature gauge. On modern vehicles, the ECT sensor reports directly to the ECM. That signal is then transmitted via bus communications to the instrument cluster. On some applications, gauge operation can by verified by using a bi-directional test to “sweep” the cluster gauges.

Due to differences between the reflectivity of the target surface and actual coolant temperatures, a minor variation between measured and datastream temperatures might be observed when using a non-contact pyrometer. See Photo 4.

ELECTRICAL FAILURES

Let’s look at a P0117 and P0118, which indicate, respectively, a low- or high-voltage signal problem within the ECT signal circuit. For our 2008 Subaru Outback with the 2.5L 16-valve “H4” engine, the driveability symptoms include:

- Hard to start;

- Improper idling; and

- Poor driving performance.

I won’t get into the details of the Subaru diagnostic chart for P0117, suffice it to say that the low signal voltage will be caused by:

- An open circuit;

- A shorted circuit; or

- An out-of-calibration ECT sensor.

In contrast to the OE method of testing ground resistance, etc., my preferred method for diagnosing ECT faults is to graph the ECT warm-up voltage on a scan tool. As ECT voltage is graphed, the circuit can be wiggle-tested for broken wires and corroded connections. If the ECT voltage and ECT PID doesn’t correspond to actual engine temperature, the ECT sensor isn’t calibrated correctly. With that said, a typical ECT PID should indicate -40º F when disconnected. If ECT reference voltage is jumpered to the ECT signal wire (which is grounded through the ECM), the ECT PID should typically indicate approximately +300º F.

Moving on through ECT circuit diagnostics, our Subaru’s ECM is looking for a “target” signal of at least 0.2647 volts. The ECT monitor requires 500 milliseconds to detect the failure and the MIL illuminates shortly thereafter. Since 40 idling cycles are required to automatically clear the P0117 DTC, it pays to look at history codes for evidence of ECT electrical malfunctions.

Most important, let’s look at what happens during a P0117/118 circuit failure. With our Subaru, the ECM goes into a fail-safe mode that fixes ECT at a default value of 158º F. According to service information, the idle speed will correspond to the default temperature value and the idle speed control (ISC) will not perform a re-learn. The air conditioner will not turn on and the engine cooling fans will default to high-speed output. The variable valve timing will also default to 0% duty cycle.

While the P0128, P0117 and P0118 DTCs are indicative of many common cooling system problems, they also indicate how engine operating systems can be affected by incorrectly calibrated thermostats. In any case, when pursuing intermittent or random driveability and stalling complaints, it’s wise to check for cooling system-related DTCs and to pursue a basic cooling system diagnosis before jumping to any diagnostic conclusions.