Recommending and selling loaded strut assemblies not only makes for happier, safer and more profitable technicians, it also provides the customer with the benefit of completely new components. In addition to the strut itself, a loaded strut includes the upper strut mount, strut bumper and boot, spring seat and insulators, and coil spring. Prior to the availability of loaded struts, our choices were to source each of these parts individually or reuse the parts where replacements weren’t readily available. Recycling these used components certainly doesn’t help improve the ride or handling of the vehicle, and may lead an unsatisfied customer back at your counter with a ride control complaint when one of these components reaches the end of its service life well before the new struts begin to age.

Recommending and selling loaded strut assemblies not only makes for happier, safer and more profitable technicians, it also provides the customer with the benefit of completely new components. In addition to the strut itself, a loaded strut includes the upper strut mount, strut bumper and boot, spring seat and insulators, and coil spring. Prior to the availability of loaded struts, our choices were to source each of these parts individually or reuse the parts where replacements weren’t readily available. Recycling these used components certainly doesn’t help improve the ride or handling of the vehicle, and may lead an unsatisfied customer back at your counter with a ride control complaint when one of these components reaches the end of its service life well before the new struts begin to age.

The benefits of choosing a loaded strut assembly can also be easily communicated to your customer in terms of monetary value and convenience. The value of the loaded strut can be expressed as a comparison between the costs of both parts and labor when compared to conventional strut replacement. While a customer’s initial investment in purchasing a loaded strut can be significantly higher than that of just a mount and “bare” strut, this sort of objection is an apples-to-oranges comparison.

To really give the customer an apples-to-apples comparison, you may opt to write your estimate in two sections. The loaded strut option will be very straightforward, and quite short, too. Since everything required for each assembly is contained in one SKU, there will be at most four lines for parts and then a line for labor. For the second section, give the customer a breakdown of the cost for each individual component required for a complete repair, explaining that each of these pieces is already included in the cost of the loaded assembly. When purchased individually, these components tend to add up quickly, and often exceed the cost of the pre-assembled unit. Itemize the difference in labor costs, pointing out the additional time required to “rebuild” the strut, which is above and beyond the time already required for removal and reinstallation.

To really give the customer an apples-to-apples comparison, you may opt to write your estimate in two sections. The loaded strut option will be very straightforward, and quite short, too. Since everything required for each assembly is contained in one SKU, there will be at most four lines for parts and then a line for labor. For the second section, give the customer a breakdown of the cost for each individual component required for a complete repair, explaining that each of these pieces is already included in the cost of the loaded assembly. When purchased individually, these components tend to add up quickly, and often exceed the cost of the pre-assembled unit. Itemize the difference in labor costs, pointing out the additional time required to “rebuild” the strut, which is above and beyond the time already required for removal and reinstallation.

Labor time can be viewed in terms of convenience, as well. You have a set labor rate, indicating that each hour of your time is worth a specified amount of money. Your customer’s time is valuable, as well, and the labor saved by installing loaded struts can be of benefit to both of you. For your customer, it means getting their vehicle back that much sooner and getting their schedule back to normal. For you, decreased labor times can leave room in the schedule for additional appointments, increasing your daily car count. The other benefit is that recommending the loaded strut cuts down on those unforeseen delays caused by missing or worn-out parts. While a good parts store keeps an excellent selection of loaded struts in stock, many of the smaller individual strut components required to complete a traditional strut repair are often non-stocking or special-order items. Selling the complete strut assembly can prevent those disappointing late-afternoon phone calls to inform your customer that their vehicle is laid up on the lift and may not be ready for another day or more.

Giving the customer options not only allows you to show them the value and convenience of purchasing a loaded strut, it gives them some sense of involvement in the decision. If the customer becomes more involved, they may also feel more confident and more in control of their choice. Strut replacement can be a significant repair cost, so some hesitation before “pulling the trigger” is common. A hesitant customer, when presented with a single “take it or leave it” option, has more opportunity to reject the proposal completely. Taking the time to explain the features and benefits of each option, including performance, cost, service life and warranty, is a great way to both sell and educate your customer.

Giving the customer options not only allows you to show them the value and convenience of purchasing a loaded strut, it gives them some sense of involvement in the decision. If the customer becomes more involved, they may also feel more confident and more in control of their choice. Strut replacement can be a significant repair cost, so some hesitation before “pulling the trigger” is common. A hesitant customer, when presented with a single “take it or leave it” option, has more opportunity to reject the proposal completely. Taking the time to explain the features and benefits of each option, including performance, cost, service life and warranty, is a great way to both sell and educate your customer.

Presenting multiple options, especially when they include perceptions of quality or savings, increases the chances that they will be open to accepting at least one of them. Leading your pitch with a premium product gives you the opportunity to make a profitable sale if the customer is immediately agreeable, but it also leaves you with options to fall back on if necessary. Many ride control suppliers now offer loaded strut assemblies in various quality (and price) levels for popular vehicle applications; so, there are additional opportunities to make a sale if your initial offerings are rejected.

There is little glory in just having the “best price in town.” That reputation only attracts the sort of clientele you don’t need, and it can actually drive away the types of customers who are willing to pay a premium for the quality parts and superior service you offer. It is more important to offer the highest-quality repair solution that is appropriate for your customer’s needs, and then explain why it is worth spending their hard-earned money for your services. Even if the customer leaves your shop without making the appointment, you have given them a detailed estimate and helped them make an informed decision about their upcoming repair needs. When the customer does commit to this purchase, you should find yourself at the top of their list.

Inspecting A New Loaded Strut

When unboxing a new loaded ride control unit, it can be difficult to determine if it will function like the original unit. Here are the top items you should be looking at when selecting a new unit.

1. The Spring

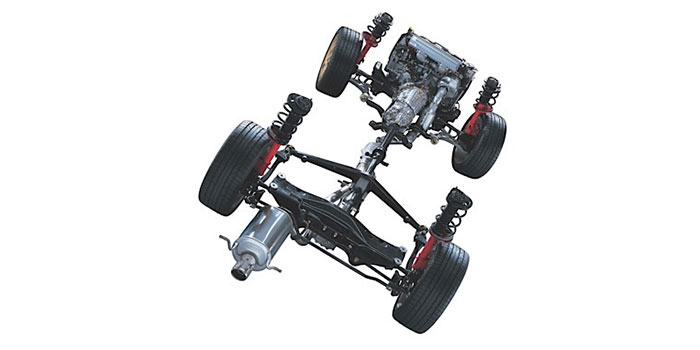

The spring is the one item on a loaded shock or strut that can show if the manufacturer did their homework. A modern helical spring is a very complex item. On most modern springs, the coils will vary in size and geometry to achieve the best ride at a specific distance of wheel travel.

The first clue as to part quality could be the number of coils on the spring. Sometimes the manufacturer might save material by reducing the number of coils when compared to the original. They will even change the diameter of the wire.

The shape of the spring also matters. Spring geometry, in terms of spring compression rate, will change depending on wheel displacement. In some cases, a spring can generate side loads that help the dampening forces of the unit under certain conditions. This is why the position of the spring on the seat matters on some vehicles, and the spring may look off-center on the strut.

What is unseen is the quality of the steel used for the spring and how it was heat-treated and annealed. These factors can determine how much the ride height changes over the life of the spring. The quality of the steel in the spring can cause the spring to break, creating a possible catastrophic failure.

2. The Shock or Strut

The dampener body of the unit may also clue you in to the quality of the unit. If the body is smaller in diameter than the original, the unit will not be able to dampen the movement of the spring properly. Smaller bores and less oil volume could mean the unit has to work harder, which means more heat. As the unit heats up, it could fade and cause bubbles in the fluid. Length is another issue. If the unit is too short, it could lock at full rebound.

The shaft is another clue. Look at the diameter and finish of the shaft compared to the original unit. The shaft is a part of the suspension that is just as critical as a control arm or ball joint.

The unseen metallurgy of the shaft could make for a piece that breaks, instead of bending during a curb strike.

3. Mounts and Bushings

Look at the mounts and bushings of the new unit. The upper mount and bearing plate should match the original unit. Deviating from the original design can save the manufacturer money, but it will cause changes to the steering feel. Changes in the upper strut mount materials and design can affect how road noise, vibration and harshness is transmitted through the body.

Bushings are another visual indicator of the quality of the new unit. The 2004-2008 Ford F-150 is a prime example. The lower bushing on the shock is designed to rotate as the lower control moves in an arc. If the incorrect bushing material or design is used, the unit will not work properly and will bind. In some cases, it will result in a noisy suspension, or the bushing could fail and affect performance and ride height.

You can take your chance with a budget-price loaded ride control unit, but the price from the supplier does not cover the cost to your reputation.

Courtesy Brake & Front End.