The desire for enhanced vehicle performance is often the driver of evolution in the automotive industry. But when a state-led charge to reduce water pollution caused, in part, by brake pad dust began to gain momentum in the first half of this decade, representatives from the brake manufacturing industry coordinated with representatives from the vehicle industry, the U.S. Environmental Protection Agency (EPA) and the Environmental Council of the States (ECOS) to get ahead of the problem.

On Jan. 21, 2015, the EPA, ECOS and eight automotive industry groups signed off on an agreement to gradually reduce the use of copper and other hazardous materials in brake pads after evidence showed water runoff containing brake dust contaminates was one source of elevated copper levels in streams, rivers and other waterways.

Taking a cue from California and Washington, whose legislatures both enacted separate laws in 2010 to gradually phase out copper from brake pads, the above groups signed a voluntary Memorandum of Understanding (MOU) calling for brake pad manufacturers to reduce copper in brake pads to below 5% by weight by 2021 and below 0.5% by 2025. This MOU, which is commonly referred to as the Copper-free Brake Initiative, simultaneously called for the reduction of mercury, lead, cadmium, asbestiform fibers and chromium (VI)-salts in brake pad formulations.

Implication For Manufacturers and Repair Shops

Spurred by the laws enacted by California and Washington, several other states such as New York, Hawaii, Rhode Island and Oregon drafted legislation over the past several years aimed at reducing brake pad pollution. However, the Copper-free Brake Initiative, in tandem with California and Washington’s existing laws, effectively made other state-specific laws unnecessary. This is because while the Copper-free Brake Initiative was voluntary and not legally binding, the laws enacted in California and Washington effectively set an unwritten nationwide mandate for compliance for all parts manufacturers.

“The laws in the states of California and Washington effectively created an industry-wide ‘de facto’ standard,” Leigh Merino, Senior Director of Regulatory Affairs for the Motor & Equipment Manufacturers Association (MEMA) told Brake & Front End. MEMA, which represents the Automotive Aftermarket Suppliers Association (AASA) Brake Manufacturers Council (BMC), was one of the organizations that signed off on the MOU.

“Many brake friction material manufacturers are changing their U.S. products to be compliant with the states’ requirements in order to be sold in all states,” Merino said. “The MOU, which is based on the timelines and requirements of California and Washington, was necessary to establish a national-level program to ensure consistency in reporting requirements and recognition of the industry’s compliance with those laws. Brake manufacturers, vehicle manufacturers and other key stakeholders have fully supported the efforts.”

Merino noted that as of March 2016, every member of the BMC had registered new product identities in the state of Washington in an effort to get ahead of the curve with their reduced-copper lines. Many of the reduced-copper brake pads hitting the market today even boast greater stopping power, longer life, reduced dusting, quieter performance and greater fade resistance.

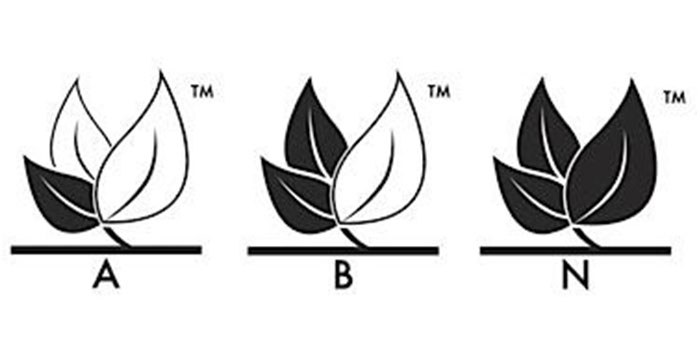

Manufacturers have already embraced the use of brake pad packaging denoting compliant products to help shops understand what they’re buying. Going forward, all pads and shoes must have a manufacturer’s edge code showing the product’s level of compliance with state legislation. Additionally, the BMC developed the LeafMark emblem in 2012 to spell out each pad’s level of compliance with industry standards. The LeafMark has three different gradings:

Manufacturers have already embraced the use of brake pad packaging denoting compliant products to help shops understand what they’re buying. Going forward, all pads and shoes must have a manufacturer’s edge code showing the product’s level of compliance with state legislation. Additionally, the BMC developed the LeafMark emblem in 2012 to spell out each pad’s level of compliance with industry standards. The LeafMark has three different gradings:

Level “A”: Currently in Effect

- Contains more than 5% of copper by weight

- Asbestiform fibers, less than 0.1% by weight

- Cadmium and its compounds, less than 0.01% by weight

- Chromium (VI)-salts, less than 0.1% by weight

- Lead and its compounds, less than 0.1% by weight

- Mercury and its compounds, less than 0.1% by weight

Level “B”: Effective Date on or After Jan. 1, 2021

- Contains between 0.5% and 5% of copper by weight

- Asbestiform fibers, less than 0.1% by weight

- Cadmium and its compounds, less than 0.01% by weight

- Chromium (VI)-salts, less than 0.1% by weight

- Lead and its compounds, less than 0.1% by weight

- Mercury and its compounds, less than 0.1% by weight

Level “N”: Effective Date on or After Jan. 1, 2025

- Contains less than 0.5% of copper by weight

- Asbestiform fibers, less than 0.1% by weight

- Cadmium and its compounds, less than 0.01% by weight

- Chromium (VI)-salts, less than 0.1% by weight

- Lead and its compounds, less than 0.1% by weight

- Mercury and its compounds, less than 0.1% by weight

Although California and Washington’s state laws differ slightly on certain exemptions and effective dates regarding the phasing out of traditional copper brake pads, as a general best practice, repair shops should be focused on buying brake pads with the designated LeafMark on the package or with an edge code that correlates to the implementation deadlines in effect.

The MEMA/AASA/BMC and the Auto Care Association have come together to conduct industry outreach and have developed the website www.copperfreebrakes.org as a way to help technicians keep up with this shift in industry regulations. Additionally, the EPA and its affiliated state partners have created the website www.epa.gov/npdes/copper-free-brake-initiative to help keep industry participants informed on changes in the Copper-free Brake Initiative.

Courtesy Brake & Front End.