Understanding ABS Modulator Problems

Mechanical issues with the ABS modulator, or hydraulic control units (HCU), are rare, but they can happen. With more and more vehicles on the roads with older ABS systems that have not seen proper brake fluid maintenance, mechanical issues are becoming more common.

The signs of a malfunctioning ABS modulator can mimic problems with calipers, brake hoses or the master cylinder. Common complaints often include pulling brakes, long stops and low brake pedal. The main cause of these issues is the valve seats and pintles can become stuck or not seat properly due to debris, corrosion or contaminated brake fluid.

Corrosion results in the depletion of the buffers and anti-corrosion additives in the brake fluid, as the ABS modulator has a variety of metals in close contact. As the brake fluid corrodes the lines that are brazed with copper and the ferrous components, ions of the metals are release into the fluid. Since the ABS modulator has different metals, they act as anodes and cathodes. Some attract ions of copper while others are eaten away.

For a valve in the ABS modulator, the ions can plate the pintles and seats. This can prevent operation by causing it to stick and even stay open.

Theory of Operation

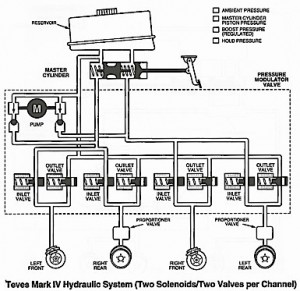

To diagnoses ABS modulator valve problems, you have to know how they work to apply, hold or release the brakes. Each brake corner has two valves. The inlet/isolation valve isolates the brake corner from the ABS pump/accumulator and the master cylinder. The outlet/dump valve allows brake pressure to be released. These valves work together to perform the following braking tasks:

Apply

When the master cylinder applies pressure, it goes directly to the wheel because the outlet/dump solenoid is closed. This is a normal braking event. The unit is in a “passive” state. It is also the position the ABS system will go to if the system is disabled.

Hold

If the system senses a wheel is locked, the inlet/isolation solenoid is closed to prevent any more pressure from the master from reaching the wheel. The wheel might start to turn. This can create a brake-pull condition.

Release

If the wheel does not start to turn, the outlet/dump valve will open. This will release or bleed off the hydraulic pressure that is holding the wheel. The wheel will now rotate.

Reapply

Since pressure from the master cylinder has been bled off, the pump in the ABS modulator will spool up and apply pressure. The outlet valve is closed and the inlet valve is opened. The pump applies pressure to the wheel. If the wheel is still outside the wheel slip parameters, the cycle will start over. This happens very quickly. The operation of the solenoids and pump will cause a “kick back” or pulsation in the pedal.

Diagnostic Modes

If the inlet/isolation valve is stuck open, it will not affect normal braking in any way; it will only hurt the ABS system. This could lead to a pulling condition during ABS activation. If an outlet/dump valve is stuck open in one circuit, this could cause a pull condition during normal braking. This is due to the loss of brake pressure at a wheel.

If more than one valve leaks or is not able to seat, it could cause a longer than normal stop if the ABS is activated.

Codes

Sometimes a stuck or defective solenoid or pump will set a code. This code will typically deactivate the ABS system. Testing the unit with a scan tool with bi-directional control might be the best way to confirm the condition of the ABS modulator.

Courtesy Brake & Front End.