he flagship LS Series.

The GS, and more recently, the IS platforms, are high-quality, performance luxury models with a conventional front engine, rear-drive or all-wheel-drive layout.

Initially, these cars were powered by an in-line six-cylinder from the Toyota Supra line.

Later models have gone to V6 and V8 powerplants. Since these cars are somewhat rare (you have to look to spot one on the road), many people would mistake them for their luxury “fluff mobile” cousins in the LS class.

However, just because they are considered a “luxury” vehicle, doesn’t mean you should turn this work away. The engine powering these vehicles has some similarities to some of its Toyota-model cousins that you have more than likely seen in your shop.

The focus of this article will be the timing belt replacement on a 2001 GS 300 with the in-line six-cylinder 2JZ-GE engine with VVT-i (Toyota’s variable valve timing).

Nothing can spoil the resale value of a high-dollar car more than an engine failure. Due to the complexities of the valve timing and internal engine clearances, these engines will most likely bend valves if the belt fails, or if the belt is installed incorrectly.

For these reasons, I would recommend that you read through this article and the service manual description for this job very carefully before starting this repair. There are also differences between models on this platform that can impact the way certain components are removed.

Know When to Say When

Recommended replacement intervals for timing belts are all over the map these days. Depending on which tech manual or tech assistance site you access, you can get widely varying mileage and time suggestions.

So when should you recommend the timing belt replacement?

Did You Know?

Did You Know?

The 2JZ-GE provided output rated at 220 hp at 5,800 to 6,000 rpm and 209 to 220 ft.-lbs. (283 to 298 Nm) of torque at 3,800 to 4,800 rpm.

The engine utilizes Sequential Electronic Fuel Injection, has an aluminum head and four valves per cylinder, with some versions using VVT-i, along with a cast iron cylinder block.

The VVT-i version also featured a distributorless ignition system (DIS) in favor of the traditional distributor set-up previously seen on the 2JZ-GE design.

Despite common misconceptions, it was not a true COP (Coil-On Plug) ignition system, instead relying on one coil to fire two cylinders, one of which was by spark plug wire.

My advice is to look closely at the accessory belts, note any cracking or evidence of replacement, and then factor in the use of the car and its maintenance history.

Cars that are driven primarily in hot, dry climates will probably benefit from earlier replacement than those living in more moderate conditions.

Due to the possibility of engine damage if the belt breaks or jumps time, I would not recommend waiting beyond six years or 90,000 miles, which is the OE-recommended interval for this engine.

This is one engine you do not want falling through the cracks when it comes to preventive maintenance, if you catch my drift.

A quick scan through service bulletins, tech assistance requests and first-hand experience with this repair leads me to advise that extra care be taken on this repair.

Ensure that every step is done correctly, and the proper tools and procedures are used to prevent comebacks, driveability complaints or difficulties in completing this service.

Tackling the Job

Because of the interference possibilities, I suggest removing the ignition key and hiding it so the engine does not get cranked by mistake while the belt is off. The job is easier if it is on a hoist and the lower engine covers are removed. Drain the coolant and remove the fan shrouds.

The various models and yearly changes to this series of cars make an initial inspection worthwhile after checking a repair information source.

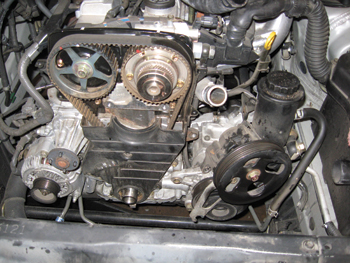

To prevent the possibility of damage, I would recommend removing the radiator and fan just to provide more working space (see Photo 1). Without removal of the radiator and shroud, space to remove the crankshaft pulley bolt is pretty much non-existent. (On SC 300 models, the battery and battery box will also need to be removed.)

To prevent the possibility of damage, I would recommend removing the radiator and fan just to provide more working space (see Photo 1). Without removal of the radiator and shroud, space to remove the crankshaft pulley bolt is pretty much non-existent. (On SC 300 models, the battery and battery box will also need to be removed.)

The serpentine belt tensioner may turn either direction depending on model, and the pulley mounting bolt will have threads of one direction or the other, depending on the adjusting rotation of the tensioner.

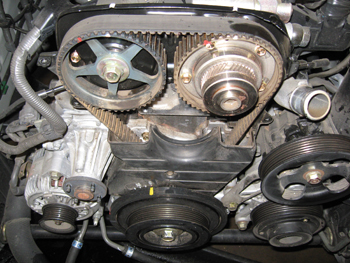

Remove or loosen the brackets for the external accessories (alternator, power steering pump and A/C compressor) as needed to allow removal of the lower front engine cover.

Depending on the year, model and body type, some accessories and their brackets are removed or can be left in place to save repair time.

The two upper timing belt covers can now be removed to allow the setting up of the engine for disassembly. Toyota designates these covers as cover 3 (the large piece with VVT-i on it) which looks like the front of a large valve cover, and cover 2, the center part of the front engine cover.

If you haven’t already done so, remove the serpentine belt tensioner. Using a suitable tool to hold the crankshaft damper, loosen, but don’t remove, the bolt and pulley at this time.

Engine Setup

In order to get the engine in the correct position for removing the timing belt, the tension on the variable timing must be removed to allow the engine to be at actual TDC.

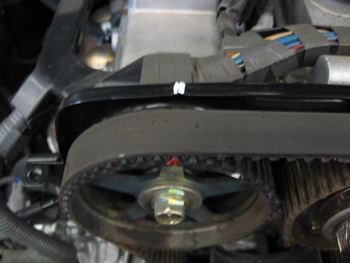

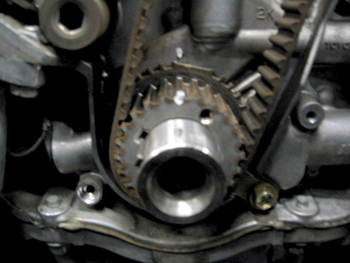

Turn the crankshaft clockwise to align the main timing mark (see Photo 2) on the damper with the “O” mark on the number 1 timing cover (lower part of front cover).

There are two marks on the crankshaft pulley and two marks on each of the camshaft sprockets. The main crankshaft timing mark is 60° counterclockwise from the sub-timing mark. The main camshaft timing marks are 30° counterclockwise from the sub-timing marks.

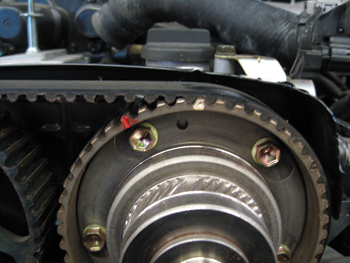

Note the location of the camshaft timing marks at this point. On this engine, I recommend that the marks be painted (preferably with different paint colors) to more easily reference the proper marks and locations (see Photo 3), with the hard-to-see marks on the number 4 timing cover (inner timing belt cover, see Photos 4a and 4b).

Obviously, if the camshaft marks are not anywhere close, turn the engine another revolution clockwise and start the alignment process again.

Once the main timing marks are located and aligned, turn the crankshaft counterclockwise to align the sub-timing marks (see Photo 5) with the same reference points used for the main timing marks. At this point, if you were planning on reusing the timing belt for some unusual reason, put an arrow on it to indicate the direction of travel.

You could also paint reference marks on the belt to speed reinstallation.

While again holding the crankshaft pulley, remove the retaining bolt. A pulley puller may be necessary to remove the pulley without moving the crankshaft. Then remove the lower number 1 timing cover (see Photo 6). Loosen the tensioner (damper) bolts evenly and take the tension off the belt.

Remove the outer belt guide (concave side goes out), and the little finger retainer that restricts movement of the belt away from the crank sprocket at the lower right side (5 o’clock position). Then remove the belt after marking the belt and sprocket, if you’re reusing the belt.

Making the Inspection

As with all timing belt replacement procedures, inspect for damage to or from the belt, oil leaks or mechanical problems (loose parts) that would shorten the life of the replacement belt. Also, inspect the old belt for cracks, uneven wear, oil or coolant saturation, or impact wear from the guides or foreign objects that might have made their way into the covers. Inspect the tensioner damper for oil leakage that would reduce the tension that it applies.

A small amount of oil may be present at the seal, but nothing more than a little seepage is acceptable. If you can depress the push rod into the housing by hand, replace the tensioner. If the rod does not stick out of the body at least 8.0 to 8.8 mm, replace it.

Make sure the tensioner pulley spins freely and that the retaining bolt is tight. Specifications call for Loctite on the retaining bolt and torquing to the proper specification. The pulley bracket should move freely; if not, make sure the spacer washer is in place between the bracket and the engine block on the retaining bolt.

If the camshaft pulleys need to be removed for seal replacement, be aware that to remove the intake variable timing pulley, only the center bolt should be removed. Do not loosen the five bolts that hold the

timing mechanism together. If there is any sign of oil leakage at the variable timing sprocket (not the camshaft seal), then the variable timing pulley may need to be replaced. Variable valve timing codes may indicate leakage or other component failure.

Service bulletins and tech assistance reports indicate that the crankshaft sprocket can be easily damaged, and cause timing and driveability problems and codes. There are reports of even small scratches on the reluctor wheel causing problems as well as missing teeth.

The standard procedure for hydraulic damper retraction is used to depress and pin the damper push rod in a vise or press. Make sure even and straight pressure are applied, and install a 1.5 mm hex wrench or pin to hold the pushrod in the retracted position. The engine should be cold by this time; if not, take a break until it is so the proper tension can be put on the new belt.

Installation Tips

The crankshaft shouldn’t have moved from its proper position, but double-check and adjust the timing mark alignment on the crank sprocket and the oil pump housing, if necessary (see Photo 7).

Make sure the front of the engine is clean and dry, and slide the new belt onto the crankshaft sprocket and over the idler/tensioner pulley. If you are reusing an old belt, make sure that you have reinstalled it in the same

position and direction. Install the little restrictor to hold the belt onto the crank sprocket. Install the lower belt guide onto the crankshaft and install the number 1 timing cover.

Install the crankshaft pulley and make sure that the crankshaft sub-timing mark is still aligned with the “O” on the cover. Install the pulley retaining bolt hand tight (do not move the crankshaft). Recheck the timing marks on the camshafts and adjust if necessary, remembering that the camshaft sub-timing marks should be the ones that are lined up with the marks on the number 4 cover (inner timing cover). Slide the timing belt onto the camshaft sprockets with slack on the tensioner side and no slack between the camshaft sprockets. Install the tensioner damper by alternately tightening the bolts after making sure the dust boot is in position.

Remove the hex wrench or pin from the tensioner body and allow a few minutes for the tensioner to stabilize pressure on the belt.

After checking that all the proper timing marks are aligned, turn the engine over by hand, clockwise only, at least two full turns and recheck timing mark alignment. There should not be any restrictions, except the

compression of the engine. If it wasn’t such a chore,

having the spark plugs out makes this step easier and more conclusive that there is no valve-to-piston contact. If the timing marks are off, redo the procedure rather than take the chance that a mistake was made. Having the marks color-coded makes verifying proper timing easier.

Tighten the crankshaft pulley bolt to the proper torque and reinstall all removed accessories, covers, radiator and fans. Use a vacuum-type cooling system filler to prevent air locks and overheating (not good for a new belt).

That’s a Wrap

Even if you haven’t seen or serviced one of these cars yet in your auto class, they are going to be around for a long time, like most Toyota products. Being prepared for routine maintenance and the peculiarities of the engine and drivetrain will put you ahead of the game when service opportunities come along. These Lexus models are superbly comfortable, extremely well made and performance is on par with the competition.

Cutlines:

Photo 1: It’s difficult to see the DOHC in-line 6-cylinder under all of the plastic covers.

Photo 2: Color-coding the timing marks will help avoid confusion.

Photo 3: The location of timing marks on the VVT-i sprocket.

Run photos a and b together

Photos 4 a & b: Marks on timing cover 4 (inner timing cover) are difficult to make out without highlighting.

Photo 5: Turn the crankshaft counterclockwise to align the sub-timing marks.

Photo 6: You may need a puller to get the pulley off without moving the crankshaft.

Photo 7: Make sure the crankshaft is aligned with the mark on the oil pump housing.