The first thing any tech must do in the bay is to know what they lifting. If possible, look at the sticker on the door jam to find out the weight of the vehicle and distribution.

The first thing any tech must do in the bay is to know what they lifting. If possible, look at the sticker on the door jam to find out the weight of the vehicle and distribution.

But, never take this number for granted. Look inside the vehicle to see what the driver is carrying and where the weight is situated.

Knowing the weight is essential in determining the center of gravity behind the front wheels. In fact, many truck stops and municipalities have scales that can be used for free.

To find center of gravity, divide the rear wheel weight by the overall weight and multiply by the wheelbase (The wheelbase is the measurement from the wheel center not the overall length). Check in the lift manual where the center of gravity of the vehicle should be placed. The placement of the center of gravity will differ on asymmetrical lifts.

Racking Up Accidents

A number of lift accidents can be traced to vehicles with unique loads like plumber trucks and vehicles with water or fluid tanks. If in doubt, weigh the vehicle. If you can’t weigh a questionable vehicle, don’t attempt to lift it, or get under it.

The same is true for sports cars and unusual cars like propane powered taxis.

Even if the vehicle is light, it does not mean it could be easy to lift. Don’t just kick the swing arm under the vehicle and hope that it will hit something solid.

Determining the center of gravity is important. Make sure to refer to the Automotive Lift Institutes lift points guide book that can be purchased at www.Autolift.org. Knowing where to lift the vehicle is becoming important due to some manufacturers using new materials and hydro-forming on some uni-bodies.

Know Your Lift

Once you know what you are lifting, you must know your lift. Your lift is one of the most important tools at the shop, and can be one of the most dangerous. The manual for the lift should be within reach or even attached to the lift.

The operating manual is a wealth of information that includes swing arm capacity and maintenance schedules, and not only how to get a vehicle down if the lift has failed.

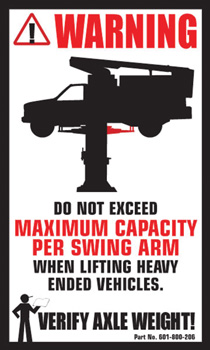

Most lifts are sold on their overall lift capacity. But, this number can become misleading when it comes to real world operation and dealing with two-post lifts. If you are operating a two-post lift, look for the individual lift arm capacity.

With most lifts, all the arms have the same lift capabilities.

This means a 10,000-lb. lift will be able to support 2,500 lbs. with each arm. If you have a loaded pickup truck that weighs 8,000 lbs., you would think that the 10,000-lb. two-post lift could easily lift it.

You could be dead wrong.

A 10,000-lb. two-post lift has an individual swing arm capacity of 2,500 lbs. If the truck has a weight distribution of 2,500 lbs. over the front axle and 5,500 lbs. over the rear, the lift arms would be overloaded by 500 lbs. It might not sound like much, but when your life is at risk, is not the time to fudge the numbers. You would need a 11,000-lb. lift.

Make sure the vehicle is always resting on the locks or load holding device. Some lifts have a hydraulic pressure gauge/weight gauge that can verify if the vehicle is resting on the locks. Most lifts start to engage locks when the vehicle is more than 19” off the ground; this is the ALI “standard.”

Some lifts engage sooner for extra safety. Keep this in mind when doing tire rotation on a dually pickup when you are only lifting the vehicle a short distance to perform a tire rotation.

Make sure there is enough room overhead. Nothing is worse than putting a box truck or RV through the roof of a shop.

Note: Some lifts include a shut-off bar in the cross member that can prevent accidents. The facts about a lift can be laid bare in the dimensional drawings. Make sure to look at arm height and how far the lift can raise a vehicle from that point. Also, measure the vehicles that your shop currently services.