The parking or emergency brake has to perform two distinct jobs. First, it must be able to hold the vehicle on an incline. Second, it must be able to stop a vehicle under a specific distance if the hydraulic brakes have failed. These standards are set by the Department of Transportation (DOT), and the kicker is these standards must be met with the force applied by a little old lady. But, over time, the cables can stretch and the friction materials change their length and thickness, which is why adjustments to the system are required.

You should never estimate when it comes to parking brake adjustments. Backing off an adjuster by feel on some drum applications can get you into trouble. Some of these applications have clearance specifications because the shoe can swell due to moisture or expand at a different rate than the drum and cause brake drag and noise.

If the manual recommends the use of a brake drum measurement and resetting tool, use one. If the manual calls for backing off the adjustment by five teeth, back it off by five teeth, not four or six.

Cables

Most modern brake cables have an inner wire that is made of stainless steel and is surrounded by an outer nylon sheath. Some cables have a dry lubricant inside to prevent binding. If you are inspecting brake cables, make sure all of the grommets and boots are in place.

The best way to keep a brake cable moving freely is to leave it alone. Many home remedies can actually shorten the life of the cable. Lubricants and oils can attract grime that can be pulled into the housing. Solvents sprayed on the cables can wash the grime farther into the sheathing and can destroy the cable.

Parking brake cables can stretch over time, which creates slack that increases lever or pedal travel. If all the adjustments are maxed out, the cable should be replaced.

Self-Adjusting Pedals and Levers

Some vehicles will have a self-adjusting parking brake that does not adjust the cables at the wheels, but at the parking brake pedal. This self-adjustment controls the length of cable that travels from the foot pedal under the dash to the equalizer bar. This is designed to keep the parking brake pedal travel the same during the entire life of the shoes. If any work is done to the parking brake at the wheels, adjustment is required.

On some GM full-sized trucks, you must adjust the shoe-to-drum clearance. Next, you will have to remove the self-adjuster lockout pin, fully apply and release the parking brake pedal three times and replace the lockout pin.

These systems have a limited amount of adjustment. Some slack can be taken out of the cable under the vehicle with a turnbuckle, but if the cable is shortened to the maximum point, replacement is required.

Some systems use an automatic-adjusting type that continuously applies minimal tension to the parking brake cables to keep them in adjustment at all times. Once the rear brakes are adjusted, just release or apply (in some cases) the parking brake lever or pedal. This will seat the parking brake cables and allow the auto adjuster in the parking brake mechanism to correctly tension the parking brake cables.

Equalizer Linkages

On most vehicles, the left and right parking brake cables come together and are attached to a lever linkage called an “equalizer” yoke under the vehicle. The equalizer yoke balances, or equalizes, the amount of force that is applied to both cables when the parking brake is engaged. The equalizer linkage, in turn, is connected to a single cable that runs to the parking brake lever or pedal. An adjustment screw may be located on the front cable where it connects to the equalizer, or where the cable attaches to the parking brake lever.

The equalizer linkage can rust up, interfering with proper application and release. The hinge pivot can also break loose and render the parking brake useless. The typical sign of a worn hinge pivot is normal travel on the lever or pedal, but the parking brake will not hold the car on a hill.

Adjustments

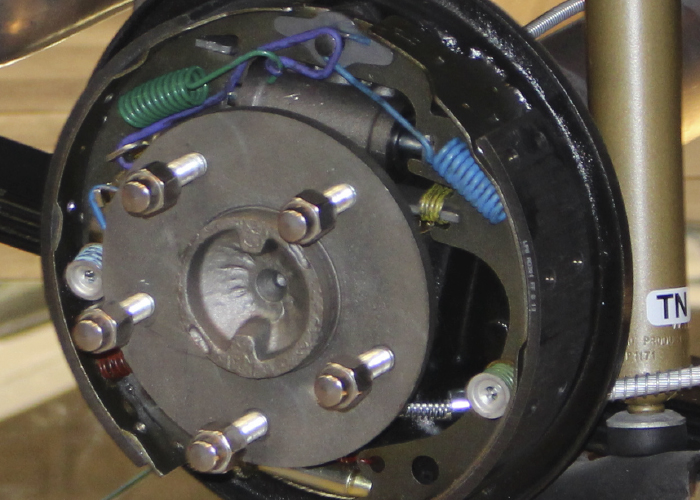

More and more parking brakes are located in the hat section of the rear rotor. Most are applied mechanically by a cable-actuated cam and lever located in the bottom or bottom of the backing plate. The shoes are attached to the backing plate with a pin and leaf spring. The shoes are held against the cam and lever with a spring.

Typically, the shoes are adjusted by rotating the star wheel on an adjusting screw located at the top of the backing plate. There is an adjusting slot located in the hat section of the rotor. It will require an old-fashioned adjusting spoon to reach the star wheel.

The most common method of adjustment is to turn the rotor and adjust the star wheel until the shoes drag on the drum. Then, back off the adjusting star until the rotor turns free. But, some manufacturers specify the use of a drum diameter gauge to set the proper gap between the drum and shoe.

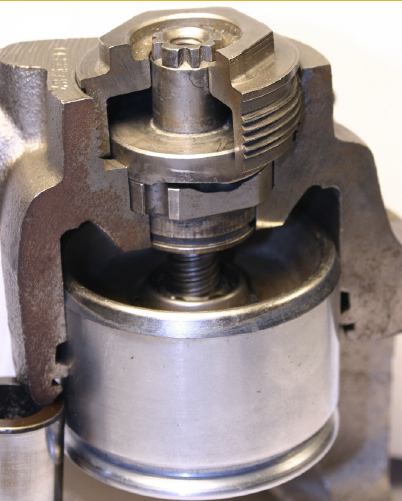

If the vehicle has rear disc brakes and the calipers have a screw-type mechanism to actuate the calipers, the adjustment procedure may require measuring the length of the cables. Typically, the caliper piston must be turned completely to the bottom of the bore to have the correct positioning for cable adjustment. The gap between the lever at the back of the caliper and stop at the rear caliper will have a specification and the brake handle should have immediate tension when pulled. If there is no tension, expect a knocking noise when it’s driven over bumps. The equalizer bar and adjuster are under the center console, which is not easy to remove.

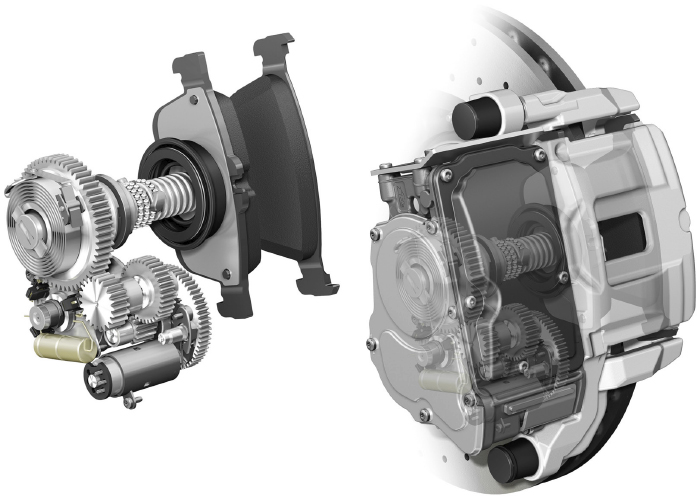

Electronic Parking Brake

A growing number of vehicles are equipped with electronic parking brakes that automatically engage the parking brake when the transmission is shifted into park. This system is great because it can reduce the length of the cable or eliminate the cable all together.

If you are doing a brake job on a vehicle with an electronic parking brake, you might need a scan tool with the proper software for the parking brake system, or a dedicated tool to reposition the cable retractor or the calipers.

Motors for cable-actuated systems are located in the passenger-side rear wheel well or under the vehicle. Most of these vehicles have procedures in the owner’s manual for disengaging the parking brake manually.

Some systems even have a program built in that adjusts for slack in the system that runs at certain intervals. Some of these systems require the use of a scan tool to adjust the parking brake while some have procedures that require pressing the lever in a certain sequence to adjust the system.