A fellow employee contacted me with a diagnostic conundrum recently. When he was driving to work, the ABS and ESC light would come on just a quarter-mile from his house, and a message in the driver information center told him that these critical safety systems were not available. It did not matter the time of day or the weather.

Was it a self-check gone wrong? No. The ABS system did a self-check during start-up and at 7 mph. The ABS system passed those checks when I drove.

When scanned, the ABS had a C1011 code for a left front wheel speed sensor for erratic performance. On my test drive, I could not replicate the condition.

The day after my test drive, he called me from our office parking lot saying the lights were on again and that I should grab my scan tool. Sure enough, code C1011 was set. I cleared the code and went for a test drive. I could not get the code to come back on and the data from the left front was not erratic and matched the right front in a straight line. Was this guy crazy?

As it turns out, no, he’s fine. He just manages to hit the same bump every day.

I asked more about when the light comes on. He said that it came on right after he drove through an intersection with a big bump caused by uneven concrete blocks before the freeway.

On the lift, the wheel bearing hub unit and ABS wheel speed sensor was secure with no damage. However, when the wheel was turned, we heard a grinding noise coming from the wheel bearing.

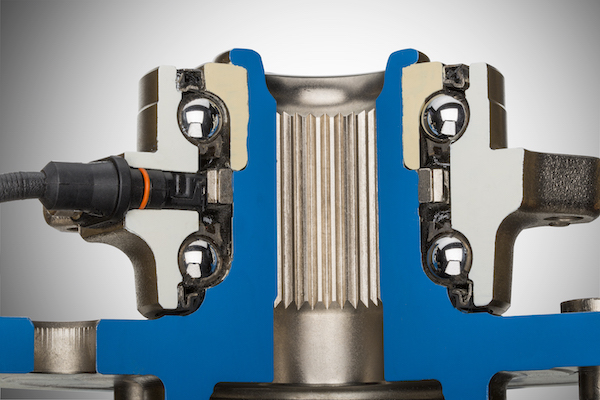

The hub unit had the reluctor ring embedded in the inboard seal. The wheel speed sensor was mounted in the knuckle. There was enough play and/or wear in the bearing that the air gap would change when he hit the bump. This change in air gap caused enough of a change in the signal to set the code.

Mechanical Diagnosis

On a typical passenger vehicle weighing around 3,400 pounds, each pair of front-wheel bearings, as well as the rear-wheel or axle bearings, support around 850 pounds, depending on the weight balance and driveline configuration. If it’s a 6,000-pound SUV, each bearing might carry about 1,500 pounds. This load is concentrated on the relatively small bearing surfaces. To understand why active wheel speed sensors fail to report the correct speed of a wheel, it is necessary to understand what happens inside the bearing and the rolling elements, and how they change the relationship of the encoder ring and the sensor.

Wheel bearing failures are event-related. Curb strikes, potholes and other incidents that may cause damage to the bearing surfaces and seals are what kill bearings, rather than an abundance of miles.

Back in the day, experiencing some play when tugging at 12 o’clock and 6 o’clock was normal. On most modern vehicles, it would take the world’s strongest man to feel any play.

Nowadays, bearing play is best measured by placing a dial indicator against the hub and turning the wheel. Refer to the vehicle manufacturer’s specifications, but as a rule, no more than 0.005˝ of play is allowed for most sealed wheel bearing and hub assemblies. This is due to the air gap tolerances between the encoder ring and sensor.

Most bearing components are heat-treated to harden the metal. But this heat-treating can penetrate only so far into the metal. Once the bearing has worn through the treated layer, rapid and catastrophic wear occurs to the softer metal below. This type of fatigue failure is called “spalling,” and the damage causes the metal to come off in flakes. The material loss of the races and rolling elements creates play and noise. When the bearing play is great enough, the seal attached to the inner race becomes dislodged from the groove in the outer race. The movement damages the seal and the encoder ring that is embedded in the seal.

After making our inspection and diagnosis, we turned to service on my co-worker’s car. The hub unit was replaced. The next day, he was in my office, happily announcing that this was the first time in weeks he had ABS and ESC the entire drive to work.

Article courtesy Brake & Front End magazine.