CC:

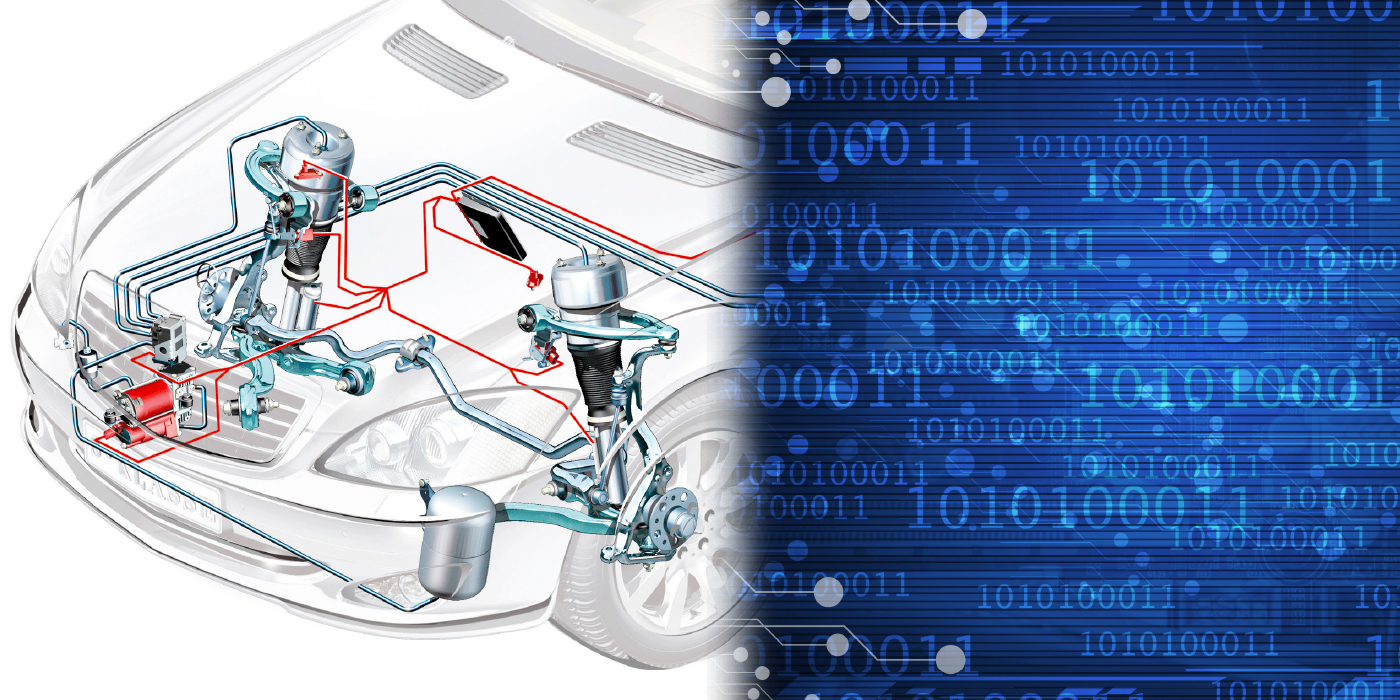

When installing a new compressor for an air ride system, there are four items you need to pay attention to.

First, inspect the mounts that attach the compressor to the vehicle. The mounts are designed to isolate vibration from reaching the driver when the compressor is running. The noise might be problematic because the noise will be intermittent due to the operation of the compressor. Make sure the springs and bushing are in good condition. This replacement Wabco compressor kit includes new springs and bushings.

Second, ensure the hoses connecting to the intake and exhaust ports are clean and not damaged. Dirt and moisture inside the intake can clog internal filters and contaminate the drier inside the compressor. Also, some vehicles may have an external filter and drier assembly that should be serviced when the compressor is replaced. The hose for the exhaust port should be secure to the compressor and vehicle. If the exhaust hose is not securely attached, it could cause excessive noise when the ride height is being adjusted.

Third, the outlet on the compressor is typically a push-to-connect or push-on type fitting. To remove the plastic line, unfasten the fitting using a line wrench and remove the metal or plastic collar and pull out the line like this. Most Wabco compressors include a new fitting and plastic line that connects the compressor to the vehicle. To install the new line and fitting, press the collar into the fitting and install. Push line into the fitting until this printed line is flush with the base of the fitting like this.To connect the line to the compressor or vehicle, push it into the fitting until this printed line is flush with the base of the fitting like this. Do not attempt to cut the line without the appropriate tools. Using the wrong tools can cause the connection to leak or introduce a restriction into the system.

Fourth, inspect the electrical connectors on the vehicle. Since most compressors are mounted to a frame rail or near a wheel well, the compressor is exposed to moisture, debris and even road salt. This can cause corrosion inside the electrical connectors. This corrosion can cause thermal damage to the connector due to the increased resistance in the circuit. If the connector on the vehicle is damaged, service it with a new pigtail harness.

If you address these four items when replacing a compressor, you can be sure that when it is turned on, it will be able to generate the pressure and volume required for the air suspension to operate like new.

This video is sponsored by Wabco.