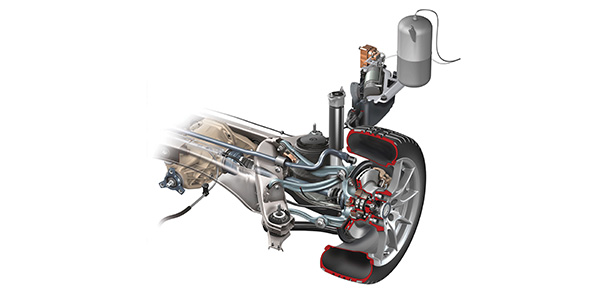

An air ride system uses three basic inputs to determine if the system is operating properly. First, the pressure sensor measures pressure at the reservoir or after the compressor. Second, the ride height sensors measure the position of the wheel in the wheel well. Third, sensors that are not directly connected to the air ride system measure the ambient air temperature, vehicle speed and system voltage.

On the control side, a system can control only the compressor and solenoids to increase or exhaust pressure at the reservoir and air springs. If the rear of the vehicle is low, a solenoid opens and pressure is sent to the air springs or bladders. While this is occurring, the pressure sensor is measuring system pressure at the compressor or reservoir. A code could be set if the correction causes too much of a pressure drop. If the correction takes too long, it will also set a code.

This is air ride at its most basic. The thing to remember is that the module is constantly analyzing the relationship between pressure and ride height. In the real world, the relationship and control system is more complex. Air ride systems can take into account the outside temperature, road surface and even if the vehicle is attached to a trailer.

What Happens When the Vehicle is in Park?

An air ride system performs a lot of work when the keys are not in the ignition. The system will trim the ride height to make sure the vehicle is not sitting on the ground, as the air in the bladders cools and contracts. During winter, the temperature difference between when the car was parked and when it is started in the morning can cause a system to set a fault message, even on a healthy system.

In addition, some systems will keep a level ride height if the vehicle is parked on an uneven surface, or if the vehicle is unlocked and a load is placed in the trunk.

Most systems have fail-safe modes that preserve the system until it can be serviced or the abnormal conditions have passed. Most units will maintain minimum pressure or height to prevent a bladder from fully compressing and the suspension from bottoming out. But, if the car sits long enough with a small leak, the reservoir will become depleted.

Why Does the Air Temperature Matter to an Air Ride System?

If air intake temperature is lower, the compressor can use denser air. In that case, the time to pressurize the reservoir should be reduced. Outside, an ambient temperature sensor or the mass airflow sensor can determine temperature. Some systems will have a thermocouple connected to the compressor. Measuring air temperature is critical because it will determine how much time it will take the compressor to fill the air springs and reservoir.

If a driver with an air ride suspension drives his vehicle home from work with an outside temperature of 32° F, and the brakes also heat the air in the bladders, the volume of air in the bladder will expand. If the driver parks the car overnight and wakes up to a 10° F morning, the air inside the bladder will have contracted and there will be less volume and pressure to support the vehicle. When he walks outside, the vehicle will be riding lower.

Air temperature also impacts the reservoir. As the temperature decreases, the volume and pressure of air in the reservoir also decreases. This means there is less capacity to trim the vehicle while it is parked and when it is running.

What Does it take to Set a Code?

The criteria that set a code will vary by vehicle. For some problems, a code might be set immediately, like in the case of a sensor or solenoid that is open or shorted. Some codes may require two or more incidents or key cycles to set a code and put the system into a safe or service mode. In some cases, the code will be cleared if the key is cycled.

On some Electronic Shock Control (ESC) systems, the ESC module can store DTCs as current or history codes. The system uses an ignition cycling diagnostic approach to reduce the occurrence of false or intermittent DTCs that do not affect the functionality of the system. This allows for the “fail-safe” actions to be taken whenever a malfunction condition is current, but requires the malfunction to be current for a certain number of ignition cycles before the corresponding malfunction code and message will be stored or displayed. This is why you get some customers who say they restarted the car and the problem was gone.

Article courtesy Import Car.