When something works, you don’t change it. This is the case with the Chrysler LX/LD platform used for the Dodge Challenger, Dodge Charger and Chrysler 300. The suspension was taken from a Mercedes platform when the company was part of Daimler. The alignment of this platform is basically the same from 2006 to 2016.

Even with the longevity of the platform, things do change due to options and model year. The biggest factor for the alignment is if the vehicle is rear-wheel-drive (RWD) or all-wheel-drive (AWD). The front suspension on a RWD model has a two-piece lower control arm while the AWD model has a single-piece control arm. Some RWD SRT models will use this arrangement.

The Dodge Charger Police Package entered service in 2006. Compared to the civilian model, the police variant’s suspension is the same, except for some changes in the sway bars, shock valving and changes to the ABS and stability control software. In 2011, Chrysler introduced a Pursuit version with heavy-duty performance front and rear suspensions with load-leveling/NIVOMAT shocks. The main goal of performing an alignment on a police Charger is to extend the life of the tires. Next to gas, tires are the largest operating expense for these vehicles.

Front Suspension

The RWD front suspension on the LX/LD platform uses a lower control arm and a lower tension strut. The AWD have a single control arm. But they share one thing in common, lack of adjustment built into the front suspension.

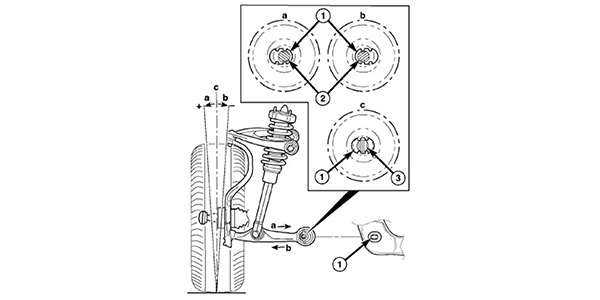

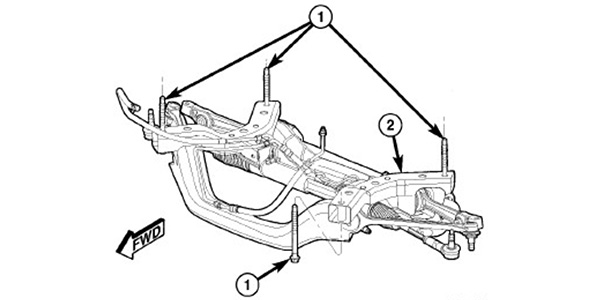

If you look at the service information, the factory recommended procedure is to shift the front cradle to correct problems. To do this you have to understand that if you are trying to add camber to one side, you are taking it away from the other side. By using this approach it is possible to adjust the camber ±.3º and ±1º of caster if the front suspension is in good working order. Chrysler recommends billing one hour of labor for this procedure.

The Chrysler bolt kit for the lower control arms and tension struts works with the uniquely grooved slots in the arms called “bat wings.” Why do they call them “bat wings?” Because they look like the Batman’s symbol when the nut is off. The bolt kit includes two grooved bolts that can adjust the camber by ±0.3º and caster by ±0.3º depending on how bolts are used. The bolts must be rotated 180° to achieve either more positive or negative camber or caster.

The better option is to install adjustable upper control arms that can adjust camber by ±2.0º and caster by ±1.5º. This option can save money for the owner during the life of the vehicle considering the vehicle may be in service for more than 200,000 miles.

The positive toe angle on the front and rear is designed to give greater straight-line stability and better turn-in performance. Which is a good thing when you are dealing with LX/LD car with a high-performance engine. Do not assume setting the toe to zero will give the best possible tire wear. This could cause a conflict with the caster angle.

Make sure you inspect the bushings, a worn bushing in the tension strut can cause changes to the camber and caster. In 2011, Chrysler used hydraulic bushings that can leak if damaged.

Rear Suspension

The rear suspension does not have built-in adjustments for camber. Aftermarket bushings can be installed in the upper links that can change the camber between ±.75º or ±1.5º depending on the bushings used and how they are placed in the links. But, it has been reported by some fleet managers that if the camber is too far out of specifications, technicians should first check for damage and the ride height before installing the bushings.

Toe is adjusted by altering the toe link’s eccentric adjusters on the cross member. When adjusting the rear toe, the lobes on the toe adjustment cam bolts and washers should only be facing upward or up to 90° to one side or the other from the 12 o’clock position.

Rear toe and camber angles change as the car squats under acceleration or rises under braking. This height-sensitive geometry feature gives the vehicle more stability. If the rear ride height is below specifications either due to heavy loads or weak springs, the inner edge of the tires will be worn. Correct any problems before proceeding with the alignment.

Article courtesy Brake & Front End.