Article courtesy BRAKE & FRONT END.

The Subaru Forester is classified as a crossover SUV. The third-generation was made from 2009-2013. What sets it apart from the Impreza it is based on is the rears suspension that uses an upper a-arm.

As part of any pre-alignment inspection, check the condition of the tires. For all Subarus, the tire brand and model should match on all four corners. Also, the amount of wear should be the same for all four tires. Subaru recommends that the tires’ circumference should not vary more than a quarter-inch when measured with a tape measure. Wear for all the tires should be within 2/32˝ of depth.

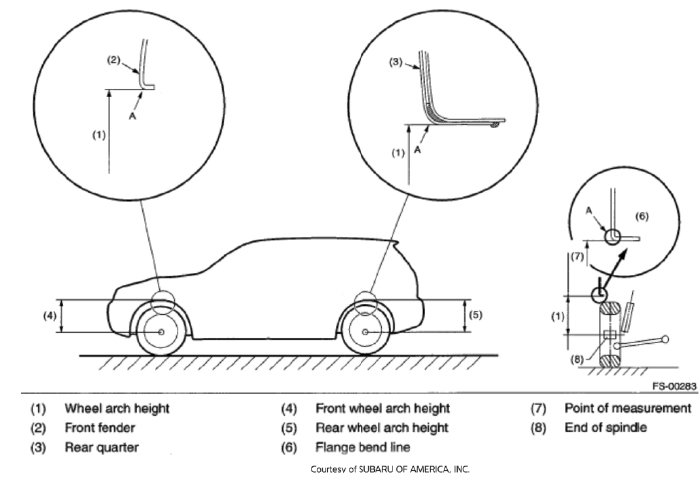

The ride height is measured using the wheel wells and the center of the wheel spindle. This simple measurement can give you an idea if there is spring or suspension damage. It can also help to explain if the front caster is out of specifications.

Front Suspension

The camber is adjustable from the factory with a cam bolt in the strut flange. Caster is non-adjustable. But if there is a large discrepancy between the caster angles, it could indicate the front subframe has shifted or there is suspension damage.

The bushings in the lower control arm wear out or can be damaged. If you see any cracks in the bushing, it needs replacement.

Rear Suspension

The rear suspension on the Forester uses a double-wishbone arrangement with a link that adjusts the toe. The toe is adjustable with an inboard cam bolt. The cam bolt offers a limited amount of adjustment; adjustable length toe links are available.

The rear camber is non-adjustable. The lower longitudinal link is not adjustable. But, aftermarket links that are adjustable with a cam bolt on the inboard side are available.

Steering Angle Sensor

If the toe or thrust angle is changed, the steering angle sensor needs to be calibrated. The procedure can be performed with a scan tool or a system integrated into the alignment system.