Many automakers are known for one particular piece of technology. Honda with its VTEC engines, Subaru’s Symmetrical All-Wheel Drive, BMW’s VANOS systems, and more. What is Audi most known for? Quattro.

The word comes from the Italian word for “four,” referring to the fact that all four wheels receive power from the drivetrain. The Quattro badge has been used for decades to identify all-wheel or four-wheel-drive vehicles in the Audi lineup.

The first vehicle to receive the Quattro was the Audi Quattro rally car, which took advantage of the recent rule change which allowed for the use of four-wheel-drive vehicles in competitive rally racing. Audi saw great success with the Quattro, racking up win after win over the next few years. The systems have evolved over the years, but the goal has remained the same: maximizing traction by sending power to all four wheels.

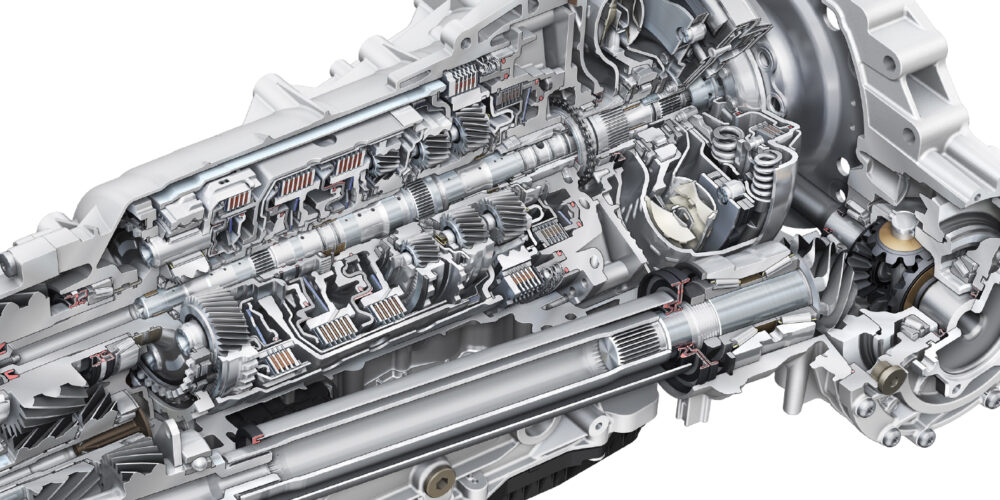

The first systems had locking differentials which could be controlled by the driver. In 1986, the Quattro system received a Torsen center differential. In 1999, some models received a viscous coupling. Since the mid-2000s, many models have a crown gear center differential. At the front and rear differentials, electrically actuated clutches work with the center differential and stability control system to send power to whichever wheel needs it.

The all-wheel-drive control module continuously calculates the best torque distribution between the front and rear axles based on data inputs from a multitude of sensors. As requirements change, hydraulic pressure is used to press the friction plates together, altering the amount of drive torque from the front axle to the rear. This process may take place inside of a differential, or inside the center differential inside the transmission, depending on the application.

The water-cooled multi-plate clutch in the center differential that distributes the necessary torque to the front wheels in any driving situation is integrated within this. There is no fixed basic distribution; in extreme cases, up to 100% can be transmitted to the front or rear axle.

The layout of the Quattro transmission has changed over the years and for different models. Most late-model Audi cars with a longitudinally mounted engine have moved the center differential to the rear of the transmission. The front differential or driveshaft on some is no longer inside the transmission.

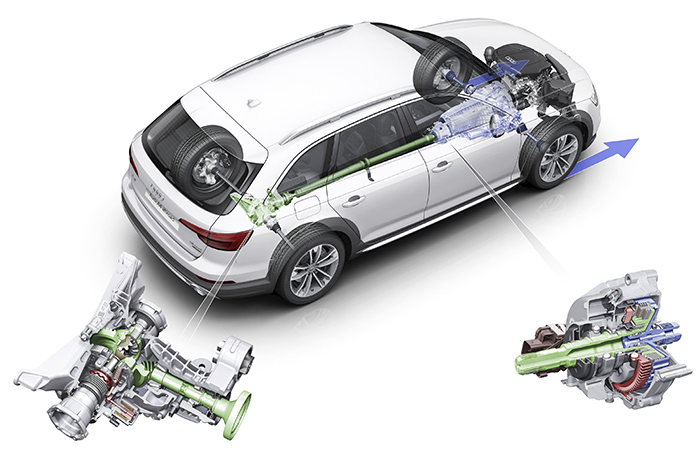

Since Audi has been sharing platforms with VWs that have a transversely mounted engine like the TT, A3 and S3, the Haldex system has made its way to Audi. The vehicles will be badged as “Quattro,” but it is a different system altogether. The Haldex coupling is mounted on the rear axle differential and is driven by the driveshaft. Engine torque is transmitted to the driveshaft through the gearbox, the front axle differential, and the front axle drive.

The driveshaft is connected to the input shaft of the Haldex coupling. In the Haldex coupling, the input shaft is separated from the output shaft to the rear axle differential. Torque can be transmitted to the rear axle differential only when the Haldex coupling clutch plates are engaged. The latest generation of Haldex units feature an updated design where the Haldex coupling is no longer on the input shaft. Instead, there are two Haldex couplings, one on each CV flange. This newer design allows for better control over how much drive torque is being sent to each rear wheel.

The Haldex coupling is controllable. A processor also makes allowance for additional information during the control process. Slip is no longer the only decisive factor in the distribution of drive forces; the car’s dynamic state is also a factor. The processor accesses the ABS wheel speed sensors and the engine control unit (accelerator pedal signal) via the CAN bus. This data provides the processor with all the information it needs on road speed, cornering, overrun or traction mode, and can respond optimally to any driving situation.

Torque input also ensures a more neutral feel while driving down the road. The sport differential is active not only under load, but also on overrun. Its torque-distributing action enhances car agility when the clutch is disengaged. Depending on steering angle, lateral acceleration, yaw angle, road speed, and other signals, the control module calculates the most suitable distribution of torque to the rear wheels for every driving situation.

When the steering wheel is turned, for example, or when the car is accelerated in a corner, power is redirected in a controlled manner to the outer rear wheel. This has the effect of “forcing” the car into the corner so that the angle of the front wheels is followed accurately. The difference in tractive force between the left and right wheels also exerts a steering effect, so that the usual corrections by the driver at the steering wheel are no longer needed. Understeer, the tendency for the car to run wide at the front when cornering, is virtually eliminated.

When approaching the car’s handling limits, the sport differential acts like ESP, but with the principle reversed. Corrective movements are not initiated solely by altering the engine settings or applying the brakes, but also by controlled redistribution of tractive force through the sport differential. The car’s forward progress becomes distinctly smoother and free-flowing because its actual road dynamics and those sensed subjectively by the driver are enhanced since ESP comes into action much less frequently.

Since its reaction time is extremely short – less than 100 milliseconds – the sport differential takes effect even more rapidly than ESP. Furthermore, ESP can react only to a discrepancy between the car’s steering angle and its actual body rotation, whereas the sport differential influences the car’s dynamic behavior before any such discrepancies occur. During sport differential action, ESP is not active. Active torque distribution is based on an entirely new design principle for the rear axle differential.

The unit can also divert torque to the outer wheel on the axle, which then rotates faster than the inner wheel when cornering. The rear axle differential has speed modulation units with multi-plate clutches mounted at the left and right sides. The clutches are activated by electro-hydraulic actuators based on input from sensors and other control modules.

Maintenance

As always, you should always refer to the OEM service information, as well as the maintenance schedule whenever trying to determine whether or not the fluid should be serviced. You should also consider the mileage of the vehicle, how much it is driven and how hard it is driven on a daily basis before coming to a decision.

With most late-model Audi differentials, there might not be a replacement interval for the fluid inside the case. In the service schedule, it is recommended that the fluid be inspected every other oil change, or every 20,000 miles. It can be impossible to observe the condition of the fluid. But, if the axle or shaft seals are leaking, the fluid needs to be replaced and the seal fixed.

For Haldex-equipped vehicles, the clutch fluid needs to be replaced every 35,000 miles. Audi Quattro vehicles can come with manual, automatic or dual-clutch (DSG) transmissions. The fluid maintenance intervals for transmissions can vary. The DSG requires fluid replacement every 35,000 miles.

When it comes to tires, Audi recommends that all four tire circumferences be within 2-4%. This means that you should avoid using different tire brands that might be the same sizes. 2-4% might not sound like much, but it can cause damage to the differentials. So, selling just two tires is not a good idea unless you can match the brand.