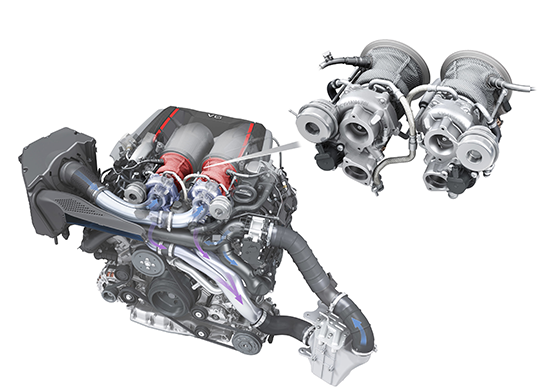

For almost a decade, Audi has been using turbos on base engines and high-performance engines. The three things all of these engines have in common are intercoolers, plumbing to connect the turbo to the engine, and valves to control boost and turbine speed. You can throw a ton of parts and labor at a TFSI or TSI engine to get the check engine light to go out for a boost issue. To solve the source of the problem you have to understand how all the components work together.

Symptoms

The signs of a leaking turbocharger system start with a lack of power or random misfires on Audi and VW engines. In some cases, the escaping boost pressure can be heard. But, if the wastegate or bypass valves are leaking, you might not hear any noise. If you get a vehicle in that is not generating enough boost, don’t automatically assume it is the turbocharger. Modern turbochargers rarely fail due to problems with the internal clearances of the turbines and shafts.

Most Audi/VW systems use multiple sensors to monitor turbocharger performance. The boost pressure sensors, MAP sensors and throttle position work together to make sure the desired pressure matches actual pressures.

If the ECM sees a large enough variance in the boost requested and the boost measured, a code will be set. The code could have the wastegate, diverter valve or sensor listed in the description. In most cases, the part contained in the code is never the one that has failed. The source of the over or under boost condition must be addressed first.

Intercoolers

On most engines, the intercooler is in front of the condenser and radiator. The location leaves the intercooler vulnerable to damage. But, one of the most susceptible areas for leaks are the mounting tabs that connect the intercooler to the vehicle. Vibration can weaken the tabs on the side tanks and cause a leak. This is why in most cases when an intercooler is replaced, it needs to be replaced with new hardware and isolators.

Valve Leaks

All turbocharged engines need a way to control the pressure in the intake manifold. The pressure can be managed on the exhaust side with a wastegate, or on the compressor side using a diverter valve.

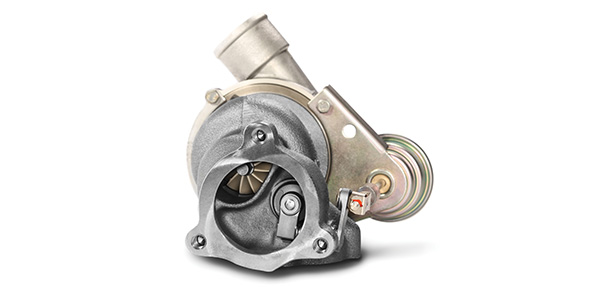

One of the most leak-prone components is the boost diverter/bypass control valve on the compressor turbine. When the valve ages, the spring gets weak, and the seal can leak under higher pressures. The actuation can be done with pressure/vacuum or an electric motor.

Wastegate valves on the exhaust side are pressure pots with a diaphragm where pressure works against spring. Old-school systems opened when the pressure reached a level where it could overcome the force of spring and open the wastegate. Modern systems manage the pressure with a solenoid so the actuation of the wastegate is more controlled. Some TFSI turbochargers now have an electronic wastegate that uses a motor to actuate the wastegate.

Wastegate leaks are typically caused by poor actuation of the wastegate caused by a weak spring or the line feeding pressure to the actuator. But, it is possible the valve and port in the turbine section can be damaged by extreme heat or carbon deposits. The housing can crack around the wastegate port. Also, the round disc can detach from the arm. The damage can be caused by misfires, unburned fuel and exhaust restrictions.

A leaking wastegate will prevent the turbocharger from spooling up and the compressor from building boost. This will result in a loss of power.

Diagnostics

Diagnosing an under-boost condition on a modern engine requires a scan tool that can graph multiple data PIDs from the data stream. The two most important parameters to look at are the desired boost pressure and the actual boost pressure during a test drive.

The first thing to see is if the boost reaches the desired level. If the boost is low, it is a sign there might be a leak in the system. If the boost is slow to build, it could be a sign there might be an issue with the wastegate or bypass leaking.

The next parameter is to look at the position or duty cycle of the bypass or wastegate valve compared to the boost pressure. Look for a change in position and a change in boost pressure.

Another essential piece of equipment is a smoke or leak detection machine. Your regular smoke machine used to diagnosis EVAP problems might not work because boost levels are, in some cases, five times higher than EVAP testing requires. But, there are high-pressure smoke machines that can detect leaks in turbocharger systems.

Boosted Crankcase Pressure

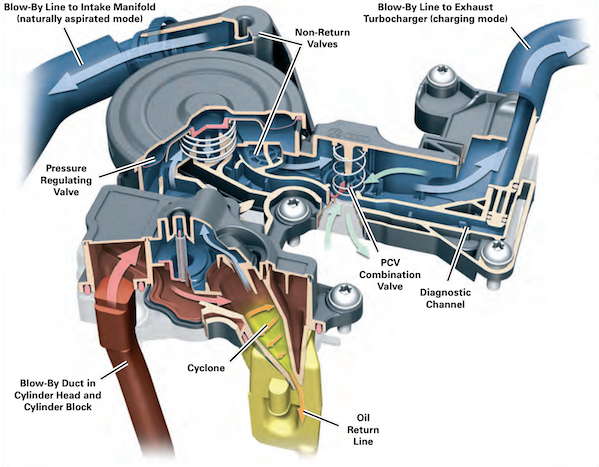

When a VW/Audi engine is turbocharged, the intake manifold is under pressure during most running conditions. The gas and oil bypassing the rings are still present. And, the pressure generated by the turbocharger can increase crankcase pressures. That’s when a more advanced PCV system is required.

Vacuum is present before the turbocharger. On some engines, the vacuum is greater than the vacuum generated by the pistons moving downward, but not all the time. Vacuum is generated only when the turbo is spinning. The area before the turbocharger is typically where the vapors from the crankcase are fed into the engine. Some turbocharged engines will feed crankcase vapors to the intake manifold with a bypass valve when the turbo is not creating enough vacuum.

Turbochargers do not like ingesting the oil that can be found in crankcase vapors. The oil can form carbon deposits on the vanes and housing and cause a loss of boost.

Modern turbocharged engines have large oil separators typically incorporated into the valve cover or on the side of the engine block. The crankcase pressure is not managed by a simple check valve. Pressures are monitored electronically or mechanically at both the crankcase and intake. The system directs the vapors to either before the turbo or intake manifold when the time is right.

These next-generation PCV systems can fail because they are exposed to high temperatures and combustion gases that can damage plastic, flexible diaphragms and seals.