Most gasoline and diesel engines require some type of fuel pump to supply the engine with fuel. Back in the early days of the automobile, no pump was needed because gravity allowed fuel to flow from a fuel tank mounted inside the vehicle to the carburetor.

Putting the fuel tank in the cowl area or under the driver’s seat was not the best location from a safety standpoint, so engine-mounted mechanical fuel pumps were introduced. A mechanical pump uses suction to pull fuel from a rear-mounted fuel tank (a much safer location) and then push it to the carburetor. For many years, mechanical fuel pumps were used exclusively in most vehicles. But mechanical pumps often leaked or broke, leaving the motorist stranded with no fuel.

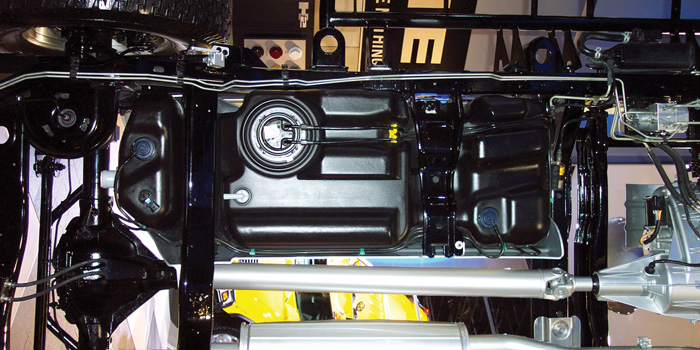

Then came the first electric pumps in the 1970s and 1980s. This innovation allowed fuel pumps to be mounted almost anywhere, and provided increased reliability and longevity. Most of these first generation pumps operated at low pressure (4 to 6 PSI) and were used with carburetors. In the mid-1980s, electronic fuel injection replaced carburetors. EFI required a high-pressure, high-volume electric fuel pump (35 to 85 PSI or higher). EFI fuel pumps are typically mounted inside the fuel tank, although some may be mounted outside the tank.

On pickup trucks with dual tanks, looking up the correct replacement pump can be tricky because you have to know if its a transfer pump between the tanks or a feeder pump inside one of the tanks. Most EFI pumps spin continuously as long as the engine is running to maintain a steady supply of fuel to the engine.

On most applications, the pump runs at a constant speed (typically 3,000 to 7,000 RPM depending on the design). However, on many newer vehicles pump speed is controlled by the PCM and will vary depending on engine load and speed. The most common type of electric fuel pump today is the turbine style pump. An impeller ring with many small blades is attached to the electric motor inside the pump.

As the motor spins, the blades push fuel through the pump housing and around the motor. Turbine pumps are quieter and smoother (no pressure pulsations) than older style pumps, draw less current and run at a higher speed. Other types of electric fuel pumps include positive displacement roller cell, vane style and gerotor pumps. The roller cell and vane pumps typically operate at 3,000 RPM, while the gerotor pumps operate at 4,000 RPM. These pumps all produce pressure pulses that may have to be dampened by a muffler in the fuel line.

These older style pumps also tend to be much noisier and troublesome than turbine style pumps. That’s why many fuel pump suppliers have upgraded their product lines and replaced many of these older style pumps with turbine pumps. In recent years, mechanical fuel pumps have made a comeback but in a much different form.

On today’s Gasoline Direct Injection (GDI) engines, an engine-mounted mechanically driven pump is used to deliver fuel under extremely high pressure to the injectors (up to 2200 PSI!). There is still an electric pump mounted inside the fuel tank, but it’s only used to push fuel to the high-pressure GDI pump. Electric fuel pumps are very reliable and can last many miles before they eventually wear out. Fuel pumps may quit working if there is an electrical problem (bad fuel pump relay or loose/corroded wiring connectors in fuel pump circuit), or they may fail if they are damaged by rust or debris inside the fuel tank.

Tank-mounted pumps require fuel for cooling and lubrication, so running out of gas can often damage the pump. On GDI engines, a common cause of failure for the high-pressure mechanical pump is improper lubrication (using the wrong motor oil). When a customer is replacing a fuel pump, the fuel tank should be inspected/cleaned as needed, and a new inline fuel filter installed unless the replacement pump is part of a fuel module assembly that incorporates a “lifetime” filter. The fuel pump inlet filer sock also should be replaced if it is not included with the replacement pump.

Article courtesy Counterman.