A Mercedes comes into the shop with a complaint of poor heater performance. The driver says during cold mornings that the heater will blow cold while he’s driving to work during rush hour traffic. The car is not overheating and the air is coming from the correct ducts.

Your first reaction might be to install a new thermostat and inspect the heater core for a blockage. During a test drive, the system may perform great for you. Is the customer just cold blooded?

The issue could be the auxiliary water pump. This pump is not connected to engine cooling. The primary function is to circulate warm coolant to the heater core. If too little coolant is circulated, the blower fan will pull enough heat out of the coolant and cause the heater core to get cold.

These pumps were first used on Mercedes-Benz diesel vehicles in the 1980s. The reason is most diesel engines typically do not generate a lot of heat when running or idling. Coupled with the lower engine speeds, the coolant in the heater core would lose most of its heat before it passed through to the outlet. This would cause drivers to complain about insufficient heating if they drove in stop-and-go traffic or cruised at speeds with lower rpm. So, adding an auxiliary coolant pump would provide enough volume of coolant to keep the heater core warm.

Mercedes-Benz then started to use these pumps on gasoline-powered vehicles like the C- and S-Class for the same purpose. This allows vehicle engineers to use larger heater cores to provide better passenger comfort.

Mercedes-Benz, Audi and BMW have also used this pump as part of the automatic temperature control system to keep the cabin heated even after the driver has turned off the ignition. The system can keep the interior warm for short periods of time while the driver goes shopping or stops for a bite to eat.

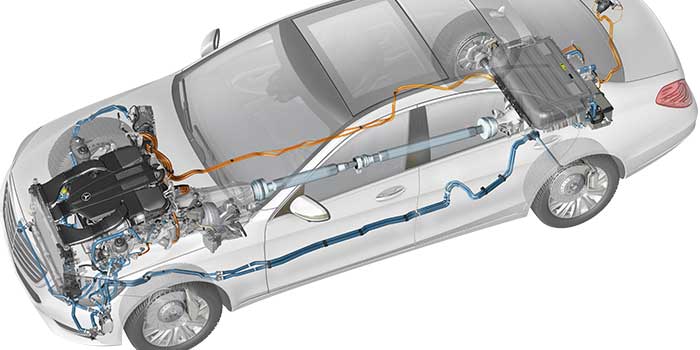

These pumps will show up on more and more vehicles as engines become more efficient and generate less excess heat. Also, new technologies like hybrid drives and stop/start systems need auxiliary pumps to not only improve driver comfort, but also to keep the batteries at a constant temperature.

MODES OF OPERATION

Note that the auxiliary pump is not running all the time. The BCM or controlling module will control and regulate the pump using information like:

- Vehicle speed;

- Engine rpm;

- Coolant temperature;

- Temperature selected on the control head;

- Blend door position;

- Fan speed; and

- Exterior and interior temperatures.

If the vehicle is equipped with Mercedes’ Stationary Ventilation system, which operates after the driver has left the vehicle, there are additional parameters that must be met to activate the pump. These include:

- Battery voltage;

- Supply voltage to the blower motor;

- Recirculation flap position;

- Security module input; and

- Keyless entry fob location.

A scan tool can test the pump function in most vehicles. It’s also possible to test the system by pressing an HVAC control head button sequence listed in the service information.

CAUSES OF FAILURE

The main reason these pumps fail is age and wear of the electric motor. Like all rotating electrical devices, brushes wear and windings short. Overheating can hasten the electric pump’s failure because increased cooling system pressures can force coolant past the shaft seals. Low coolant can also cause a pump to fail because of its position, typically high in the system, either on the firewall or strut tower.

FAILURE MODES

A failed pump will almost never cause the vehicle to overheat. If the auxiliary coolant pump is inoperative, the customer might notice reduced heater performance at low speeds and at idle.

Your first instinct might be to replace the thermostat, the water pump or the heater core, but if the vehicle is equipped with an auxiliary coolant pump, you’ll need to dig a little bit deeper with your diagnostic process.

The pump rarely leaks and does not have a weep hole.

DIAGNOSIS

The tools needed to diagnose an auxiliary coolant pump include: scan tool, meter and service information — with scan tools and service information being most important for late-model vehicles. The operation of the pump is dependent on several modules and numerous sensors that are “networked.”

The first step in the diagnostic process is to check for codes with a scan tool. Unrelated codes for collision detection, door module operation and loss of communications incidents can cause deactivation of the pump. This is where service information can make the difference between a quick diagnostic process and parts swapping.

Newer vehicles may vary the voltage-to-control pump speed. Like all electrical devices on a vehicle, the operation is a balancing act between driver comfort and minimizing electrical loads on the alternator.

The cooling circuit on some vehicles with electric pumps may be called an auxiliary cooling circuit in the service information. The coolant may travel through the transmission cooler and windshield washer fluid bottle as part of the circuit on some Mercedes-Benz models.

HYBRIDS

Hybrids almost always have an electric water pump to cool the battery packs and inverters, and some hybrids will have a second pump for the heater core in the cabin. Hybrids or mild hybrids with stop/start systems not only have an auxiliary cooling pump, but electric pumps for the oil and transmission fluid.

On certain hybrids, if a pump fails, the system will disable the hybrid drive system or put the vehicle into a limp mode. Most hybrids also have an insulated coolant reservoir or jug that may have a pump of its own to help warm up the engine faster or keep the batteries at a constant temperature.

CONCLUSION

Not every car has an auxiliary water pump, but those that do can throw a monkey wrench in your normal diagnostic logic when solving cooling system problems. Keep in mind, most Mercedes-Benz vehicles made after 1999 have these auxiliary coolant pumps, including everything from the C-Class to the S-Class.

If you think there is a problem, you not only have to troubleshoot the pump, but the system that controls it.