XDrive Transfer Case ATX13-X

MODELS

F90 (M5 Sedan), F91 (M8 Convertible), F92 (M8 Coupe), F95 (X5 M), F96 (X6 M), F97 (X3 M), F98 (X4 M), G01 (X3), G02 (X4), G05 (X5), G07 (X7), G12 (7 Series Sedan), G14 (8 Series Convertible), G15 (8 Series Coupe), G16 (8 Series Gran Coupe), G20 (3 Series Sedan), G30 (5 Series Sedan), G32 (640i xDrive Gran Turismo)

Reference Number(s):

SIB 27 02 20

Situation:

There is a jerking or shuddering during either or both of the following:

- Cornering or accelerating from low speeds.

- Driving with low to medium loads.

There are no warning lights or Check Control messages.

Cause:

Unevenly worn or incorrect fitment tires are installed on the vehicle, or the factory-filled transfer case oil does not meet BMW specifications.

Procedure:

1. Check the tires:

- Check the size and brand for correct fitment to the vehicle (use the tire placard on driver’s B-pillar for factory-fitted tire sizes).

- One or more tires with extreme tire wear will keep the xDrive engaged.

- If tires are brand new (just replaced), the issue could have happened with old tires.

- If the vehicle was equipped with staggered sizes, check to make sure they are not mismatched to axle (front are now on rear).

If no tire issues were found, or the situation still exists after the tire issues are corrected, proceed to step 2.

2. Check for and diagnose any faults in the powertrain control units.

3. To diagnose the transfer case:

- It is no longer necessary (or approved) to unplug the transfer case (VTG) module on the models listed in this SIB to diagnose a transfer case-related concern.

- The VTG can be disconnected using the scan tool with the correct software.

- Follow path Vehicle Management/Troubleshooting/Function structure/Drive/Transfer box/Current fault patterns/Temporary deactivation of all-wheel-drive system.

- Follow the instructions in the test plan and test drive the vehicle with the transfer case clutch deactivated to further diagnose the related complaint.

NOTE: There will be a warning in the control display for the xDrive system that for this procedure is to be ignored. Cycling the ignition will re-activate the VTG.

4. If the complaint was eliminated with the transfer case disconnected:

- Change the oil in the transfer case. Follow service information for oil change in transfer box including used oil disposal.

- If the repair instruction is not listed for a specified vehicle using a scan tool, follow this repair procedure.

- Connect the vehicle to the scan tool. Follow path Service functions/Drive/Transfer box VTG/Oil change and follow the steps in the test plan.

- Remove the transmission cross-member following service information.

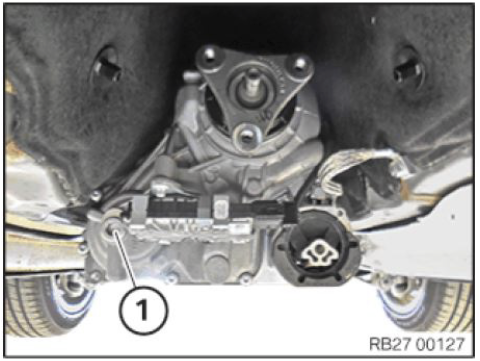

1. Open the oil filler plug (1, top photo).

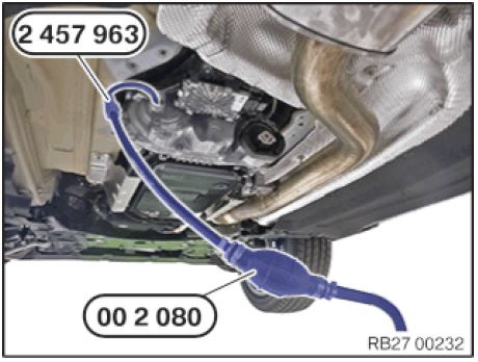

2. Extract the transmission oil from the transfer case (VTG) using an oil extractor.

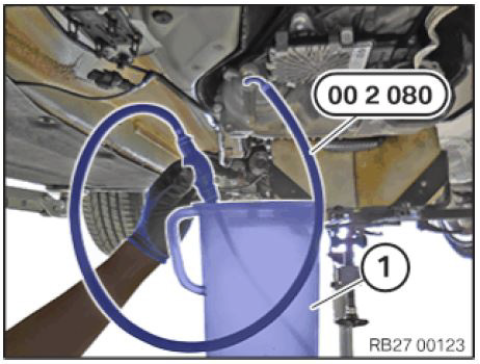

3. Top up transmission oil up to the lower edge of the opening for the oil filler plug. Use the specified fluid for the vehicle and pump in .7 liter into the case.

4. Install a new oil drain plug.

- Tighten the oil filler plug to 60 Nm.

- Reinstall the transmission cross-member following service information.

5. Re-calibrate the VTG using the scan tool. The new transfer case oil will still need to fully saturate the clutch plates inside the transfer case (up to 125 miles). The shuddering should diminish during this run-in period before completely smoothing out.