The fifth-generation Honda CR-V uses the Honda Civic platform. There is nothing special or different about the brakes compared to previous generations except for a new design for the brake pad clips and the electric parking brake. It is also required to have a scan tool with coverage to retract the rear brake calipers.

Make sure that the caliper pins are installed correctly. The upper caliper pin and the lower caliper pin are different. Installing these caliper pins in the wrong location will cause vibration and uneven or rapid brake pad wear.

Honda ditched the spreader springs in the front for the fifth-generation CR-V in favor of clips on the ears of the brake pad the decrease noise and push the pad against the caliper. These can be difficult to install, but the clips are necessary.

The most basic and often-overlooked detail is a thorough inspection of the system. While the worn pads may be the apparent problem, be sure to inspect the entire system. Take a good look at the rear pads and the condition of the brake fluid.

Don’t skimp on the brake pads. All the CR-Vs of this generation are designed to work with ceramic friction formulations. Similar friction materials must go back on the vehicle.

Don’t skip the shims. From the factory, the brakes use a floating shim. This design creates a “boundary layer” preventing vibrations from being transmitted to the caliper and knuckle. If the replacement pads do not match or exceed the original shim design, think twice about installing them.

Parking Brakes

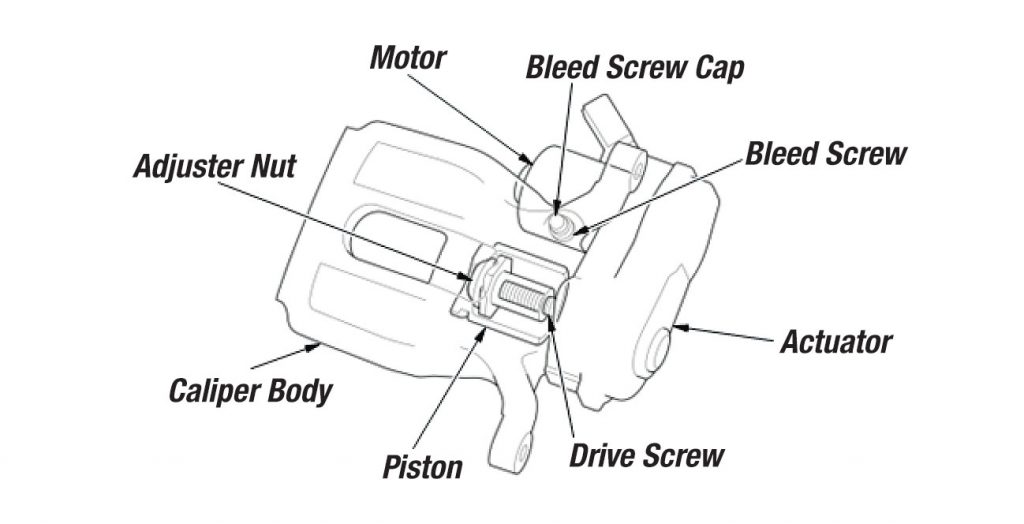

This is one of the first Hondas with an electric parking brake system. This system uses motors mounted on the calipers. The system is controlled by the Vehicle Stability Assist (VSA) module. The system has a button on the dash to engage and release the parking brakes. Firmly applying the brake pedal and pushing down on the electric parking brake switch releases it.

The electric parking brake actuators are automatically adjusted to compensate for brake pad wear, so no parking brake adjustment is necessary. if the vehicle is driven 625 miles (1,000 km) without applying the parking brake, the parking brake is automatically applied and released while vehicle is at a short stop and adjusts the brake pads. The parking brake release upon acceleration and is used for automatic rollaway prevention.

This system has two indicators on the gauge control module. When the system is OK, each indicator comes on for about two seconds after turning the vehicle to the on mode, and then it goes off. If the parking brake is applied, the brake system indicator (red) is still ON.

The amber brake system indicator comes on when the electric parking brake function is lost or the HDS maintenance mode is enabled. The red brake system indicator comes on when the park brake is engaged or the brake fluid is low. Both lights should come on for two seconds when the engine is started.

The parking brake system can set codes. The memory VSA module can hold 10 DTCs. However, when the same DTC is detected more than once, the more recent DTC is saved. This can make it difficult to determine if the problem is current or intermittent. Codes can’t be cleared by disconnecting the battery – this requires a scan tool.

When the SUV is started, the system does an initial self-diagnosis that includes bias voltage tests to the switch and motors. The system is also looking for abnormal performance with a monitor that runs constantly. When the system detects a problem, the VSA modulator-control unit shifts to fail-safe mode.

When the electric parking brake system has a malfunction and the parking brake cannot be released, you can release it in three other ways. First, you can clear the codes or attempt to actuate the parking brakes with a scan tool. If you do not have a scan to that can do this, try this:

- Buckle the driver’s seat belt.

- Start the engine.

- Shift the transmission to D or R position/mode.

- Slowly press the accelerator pedal.

If those do not release the parking brake, you can remove the motor from the caliper and retract the piston using a T45 torx driver, turn the spindle shaft clockwise until parking brake is released.

To service the rear brakes and retract the parking brake using the brake maintenance mode with a scan tool. After the brake pads are replaced, the scan tool is again required to put the system in normal mode.

Article courtesy ImportCar magazine.