Article courtesy ImportCar.

The Volkswagen Tiguan is a compact SUV built on the A5 platform that is shared with the Golf and Jetta. The brake system is straightforward, but it has two quirks that can make a brake job difficult: a vacuum pump and electric parking brakes.

Booster Problems

On the turbocharged models, the brake booster uses a vacuum pump. If the vacuum pump is failing, the customer may notice a hard brake pedal. The customer may even comment that the pedal changes as the engine warms up.

The seals are what fail on the pump. The pump is driven off the camshaft, and it is located above the transmission. Often there will be an oil leak that looks like a rear main seal issue.

Rear Brakes

Volkswagen equipped its Tiguan models with Electronic Parking Brake (EPB) technology. If you are replacing the rear pads, it will require a scan tool to retract the rear caliper pistons. After the piston is reset, you may need to reset the piston further with a clamp to fully retract the piston.

EPB allows the vehicle to engage or disengage the parking brakes at the touch of a button or a command from a module. EPB sets the parking brake when the keys are removed from the ignition.

Auto Hold

All Tiguans are equipped with Auto-Hold. When the car is braked to a standstill, Auto-Hold retains the last-applied braking pressure with the ABS modulator. If the ABS wheel speed sensors detect any rolling, the braking force is automatically increased until the car comes to a standstill again. As soon as the driver presses the accelerator again and, in the case of manual gearboxes, releases the clutch, Auto-Hold releases the brakes. This feature also works well in stop-and-go traffic.

The system can be turned on or off manually on 2010-2011 models with a button next to the parking brake button. On 2012 models, the system is on all the time. But, it can be disabled using the driver information display menus. For the system to work, the seatbelt must be fastened and the doors must be closed.

If the brake pads are worn or the caliper is seized, the driver may comment that the brakes drag or do not smoothly disengage.

Take It Easy With Pressure Bleeding

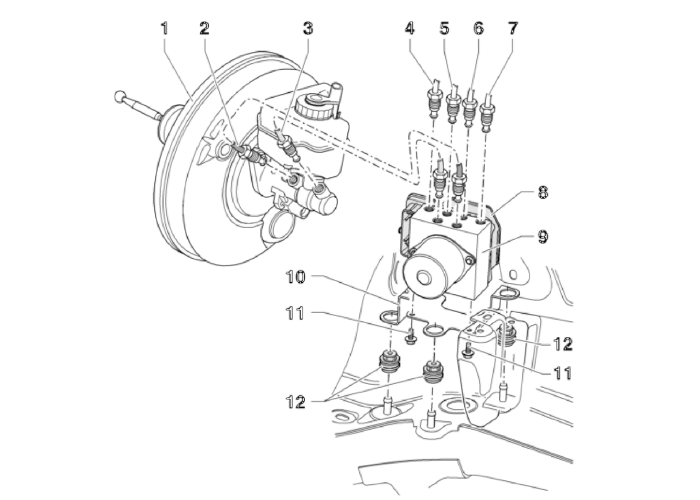

When pressure bleeding an ABS braking system, be sure not to exceed 1 bar (14.7 psi) of pressure. Pressure over 1 bar will cause the change-over valve in the EDS unit (traction control valve in the modulator body) to close, which will not allow the inner circuit of the brake system to bleed.

Pulsation Solution

Volkswagen owners may complain of a pulsating brake pedal when applying the brakes at highway speeds. The pulsation may also be felt as a vibration in the vehicle body, or the steering wheel may shake. The cause of these issues may be improperly machined brakes and lateral runout that was not eliminated. The condition may not be felt until several months after the brakes were machined. To correct the problem, measure the rotors for runout and thickness variation and correct with an on-the-car lathe.

Creaking While Braking

Some Tiguans may exhibit a creaking noise that originates in the front suspension while braking hard or going over large bumps. The source of this noise could be the forward inner control arm bushing. To confirm if this is the issue, raise the vehicle and remove the wheel on the suspected side. Disconnect the lower control arm at the ball joint and move the arm up and down, checking for noise at the forward bushing.

No Start

The brake pedal must be depressed in order to start Tiguans with automatic transmissions. If you see a Tiguan with a no-start condition in your shop, check the brake pedal switch.