Measuring brake rotors is critical to performing a pulsation-free brake job. It does not matter if the rotors are new or old, you always need to verify if they are within specification.

Lateral Runout

Lateral Runout (LRO) is defined as an inaccuracy of rotor’s plates that does not allow them to rotate exactly in line with the flange. The rotor might have the same thickness, but the plates around the flange move up and down. In layman’s terms, it is a wobble in the rotor.

The wobble can be changed in two ways. First, the rotor can be machined to match the same plane. Second, a rotor can be shimmed with a plate between the rotor and flange that changes the runout in the plates.

LRO will not cause piston movement, but rather caliper body movement. This movement causes the brake pad to make contact with the high spot of the rotor and wear. This wear can cause changes in thickness to that area of the rotor.

Disc Thickness Variation

Disc Thickness Variation (DTV) is the difference between the thickest and thinnest parts of the brake rotor. Some engineers call it parallelism. When the brakes are applied, the thickest part of the rotor pushes the piston of the caliper back into the bore of the caliper. The thinnest part of the rotor causes the piston to extend from the bore of the caliper. This has implications for the hydraulic brake components.

LRO=DTV

DTV=Pulsation

When the driver applies the brakes, the pads clamp onto the rotor. The pads and pistons follow the rotor’s high and low spots. This piston movement causes brake fluid to be displaced and the caliper becomes a pump. Since brake fluid is incompressible, this fluid movement is transferred to the master cylinder and, eventually, the brake pedal where it creates pulsation.

New Rotors Do Not Solve Pulsation Problems

New brake pads and rotors do not solve pulsation, judder or premature wear problems — they only mask the cause for a short period. In fact, the only problem new pads and rotors can solve is the elimination of parts that are below specifications.

Discard or Minimum Thickness

The discard or minimum thickness of a rotor is the dimension at which the rotor should be replaced. These specifications are not related to the ability of the rotor to absorb heat. Instead, the dimension is related to the brake piston travel and the integrity of the hydraulic system. If the rotor and pads are worn to the minimum specification, the travel of the piston is near the point where the seal and system could leak and the brake pedal will go to the floor.

Stacking

Most rotors today are manufactured with 0.0005- to 0.001-inch of LRO. Likewise, most hubs should have less than 0.002-inch of runout. But tolerances can sometimes stack up, creating too much total runout in the rotor and hub when the parts are assembled.

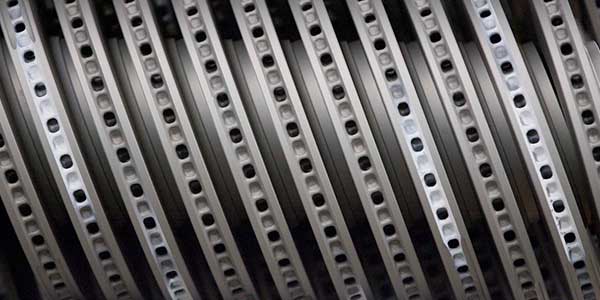

Metallurgy

You may be saying, “iron is iron.” This is not true when it comes to brake rotors. OEMs use different grades of iron to ensure that a vehicle platform has the right characteristics of wear, noise dampening and performance. Like brake pads, rotors can be vehicle specific.

Ensuring that a rotor has the right metallurgy costs the manufacturer time and money. It is not that the raw material costs more, but rather the manufacturing process may require more expensive equipment. Also, the energy costs and labor costs may be higher.

Article courtesy Brake & Front End.