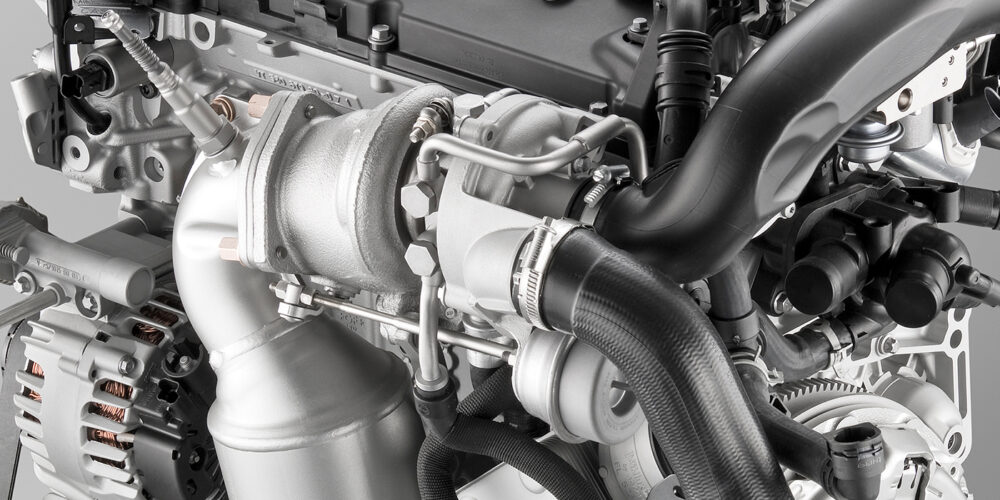

If you play in the diesel world, you’re likely a loyal fan of one of the three main light-duty diesel engine families out there – those from Dodge, Ford or Chevy. Many engine builders specialize in a couple of these engine families, or even all three, but whether you make money off of building Cummins, Power Strokes, or Duramax or not, everybody seems to has their favorite of the bunch for one reason or another.

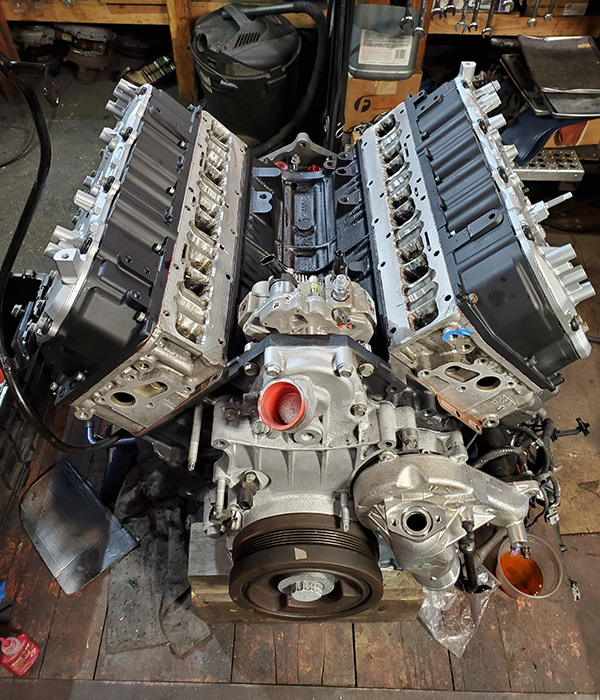

If you ask Rich Strube of Richie’s Diesel Performance in Hicksville, NY what his favorite diesel engine family is, the quick reply is Duramax. We recently caught up with Rich to take a look at why Duramax engines are at the top of his list and are for many others as well.

“The Duramax is definitely my favorite,” Strube says. “I love the V configuration. I know the Ford Power Strokes are a V as well, but getting them to stay together is a different story, and nothing against the inline sixes. As far as the platform goes and the foundation of the Duramax, it’s not the cheapest one to build by any stretch of the imagination, but it has reliability and you’re able to produce the power you want to and do it over and over again.

“I stopped doing Fords altogether because I got tired of the same things happening over and over again due to the engine design. The Cummins is a hard one to contend with because the Cummins is bulletproof. It’s awesome how well those engines are designed, but everybody’s doing it. They’re a dime a dozen.

“When it comes to the Duramax, it’s one out of every 30 or 40 guys who are playing around with those things and can successfully make clean, reliable power. That’s my specialty. I’ve got several different generations of them. The Duramax seems to make a little bit more power right off the bottom end, and they hold out that power band a little longer. You definitely get more rpms out of them. Plus, they scream and they sound sick doing it.”

Common Duramax Engines

When it comes to the different Duramax engines out there these days, there are a few that you see more often than others. What ones get built up depend on the application. The stresses of sled pulling versus drag racing versus street performance are all very different, and certain Duramax engines are better suited for each.

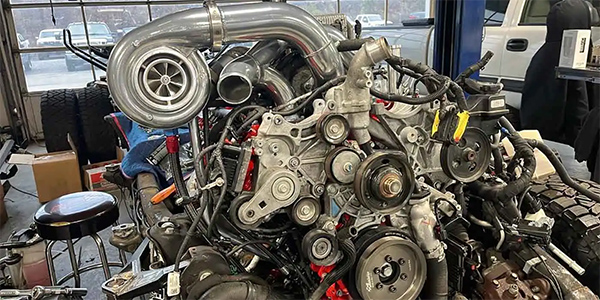

“For sled pulling, it depends whether you’re doing Street Stock, Work Stock or Modified,” Strube says. “For drag racing, it’s a little bit less expensive of a sport for the average guy to get into, so I don’t think there’s any one preferred Duramax engine. However, the guys with deep pockets tend to go with the newest ones.

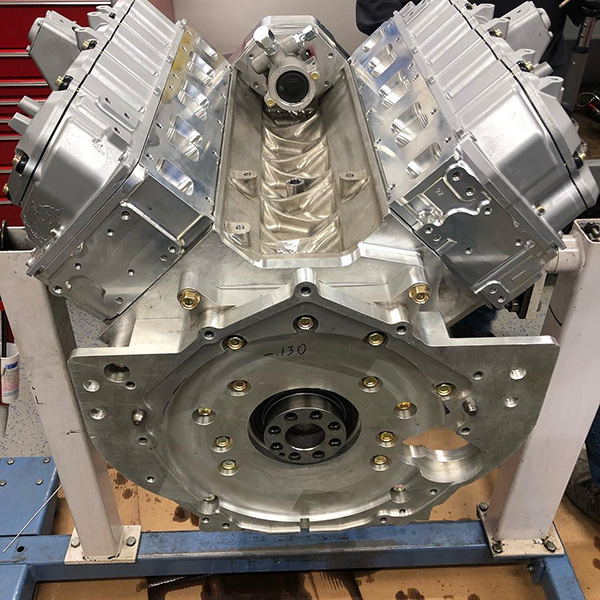

“The L5Ps have the best rotating assembly by far to date. Those are the foundations that everyone’s using for high-end competition like the 3.0 and 3.5 classes. Otherwise, they’re going to a Wagler full aluminum DX500 and so on. For the average guy who doesn’t have tons of money to spend, it depends what they can source.

“The older Duramax engines are getting harder to come by. My personal favorite is the LBZ/LMM because you don’t have to deal with the LB7 injector inside of the head deal. You don’t have to deal with LLY and its lack of airflow issues with the intake runners. They also had injector issues. When they did the LBZ, everything was so much better.”

According to Rich, the bottom ends of the LBZ were pretty similar, but they corrected the airflow issues. They also made the rods stronger than previous versions, but the pistons got weaker.

“You can change that stuff,” he says. “There’s definitely plenty of ways to address that.”

Weaknesses

While application and horsepower level are top factors that decide what Duramax is best suited to handle the performance, the different generations of Duramax engines do have certain weak points you’ll want to be aware of and get corrected.

“With the earlier ones, such as LB7s and LLYs – power contingent of course – the least that we do, besides a set of head studs, would be to address the water pumps and the reluctor ring gear on the front of the crankshaft hub,” Strube says. “Those are notorious for snapping the three bolts that hold them to the crankshaft hub. When that occurs, it’s game over from your engine. It shuts down and you cannot get a crank signal. I know this all too well because it occurred to my own truck.

“Progressing further beyond that, with the LBZ and LMM engines, GM changed the type and manufacturer of their rods and pistons. That change is a double-edged sword. The earlier ones used to have strong pistons, but weak rods. When the LBZs came out in 2006 and 2007, which were the same motor as the LLMs, those had stronger rods, but much weaker pistons.

“The reason they were weaker is they changed the dimensions from the oil ring gears to the wristpin landings, and they were notorious as soon as you put a set of injectors in there or aggressive tuning with some advanced timing, you’d wind up cracking the wristpin landing right at the bottom of the hole. That crack would run radially right across the top of the piston crown. If you were lucky enough, you’d just get some severe blow by and heavy smoke. If you were not so lucky, you’d get disconnection from the connecting rod and the piston.”

Due to the early Duramax engines having weak rods, companies like BoostLine have been developing aftermarket solutions to handle more power. Their 3-pocket I-beam rods made of 4340 steel alloy are endurance tested to more than 2,200 ft.-lbs. of torque and 1,200 horsepower.

“Depending on the age, abuse and duty of the OEM rods, we have seen them let go with as little as 500 whp,” says Nick DiBlasi, director of product management at Race Winning Brands and BoostLine. “The standard in the industry seems to say that anything over 650 whp absolutely needs aftermarket rods.

“We have a patented 3-pocket I-Beam design that gives us a robust connecting rod, while removing some of the weight in the key acceptable areas. The beam shape, radii and custom ARP 12mm bolts are some of the differentiating items that make this one of the strongest rods available. These rods combat twisting and bending 60% more than the same application in H-beam.

“By creating a rod that does not deflect under load, it allows engines to transfer the maximum amount of power through the crankshaft and to the wheels. They are scary strong. If someone breaks one of these rods, I’ll assume the engine has already exploded into many pieces because something else broke first.”

Aside from certain generation Duramaxes having weak OEM rods and pistons, Strube points out that the LML versions have had some crankshaft issues.

“We’ve had a rash of the later model engines, such as the LMLs, coming in with broken crankshafts lately,” he says. “It seems to be an issue with the crankshaft itself. It might be the resonance you get from the different firing sequence that the LMLs have. They went 2mm larger on the crankshafts in those things, but something changed and we really can’t put our finger on it. If we have an LML customer looking to build anything beyond 650 hp, then it’s getting a fully balanced Compstar Callies crank to make sure it’s good. We’re building those engines like we’d build one of the earlier ones for 1,000 hp.”

Making Power

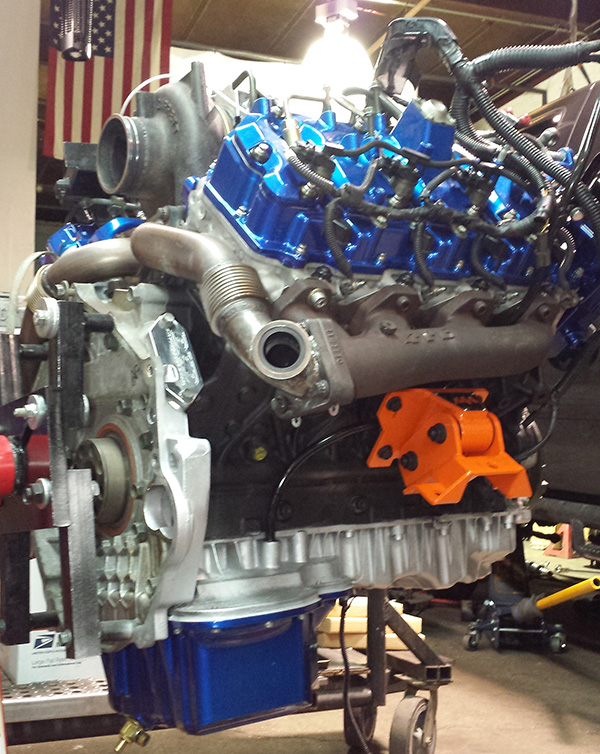

Speaking of horsepower, the Duramax platform is no slouch is this department when built up appropriately. According to Strube, his shop sees a ton of requests to build streetable 700-750 horsepower, which doesn’t require any crazy bottom end work.

“On an LBZ foundation, you can still use the stock rods,” Strube says. “They’ll be perfectly fine for 700-750 hp, but you definitely want to change the pistons. For a street engine, you don’t want to use a forged piston because the life expectancy of those is not going to be as long as a cast or a hypereutectic piston. The hypereutectic seem to be the best balance of longevity and performance. They’re not the strongest ones, but they’ll definitely take the 700-750 hp.

“We would also put a nice cam in there. With diesel, we don’t use huge lift. We change valve overlap and valve duration. On a street build, we would get a generic Stage 2 or Stage 3 cam in there. You want to do a nice set of valve springs somewhere around 116-120-lb. range. Those work well with some of the smaller cams. We would also upgrade to a 3/8ths .120˝ wall pushrod. We would also port the cylinder heads as well, which makes for a 25-45 horsepower difference.”

On the fuel side, many folks are drawn to large injectors, but Strube says those aren’t always needed. For clean, decent power, small injectors used in the right the package will do the trick.

“You don’t always need to throw a set of 200% injectors in there and two big stroker pumps and send the thing to the moon,” he says. “For a street motor, a 10mm stroker pump and a 60% set of injectors will got you a solid 700 horse engine. Depending on the size of the truck, that engine set up will run high 10s. You’ll be having a good time with it.”

Of course, for some, the 700 hp range isn’t nearly enough. Luckily, Duramax engines can appease these folks too.

“A lot of customers want to build 800-1,000 horsepower,” he says. “Then, when we build 800-1,000 hp, a year or two later, they’re back wanting to push 1,200-1,400 horsepower. For that reason, if we’re building for 1,000 hp, we’re building for 1,500 hp to be safe. That’s about the most you can get out of an externally balanced engine and not having to go too overboard with it.

“You don’t have to port heads until you get to the 1,100-1,200 horsepower range. We do pocket porting in-house. If you’re going 1,200 horsepower plus, porting the heads is a necessity, and the guys at Wagler do some sick stuff. You need that airflow. You need to be pushing all that cfm.”

As mentioned earlier, these power levels definitely require piston and rod upgrades, which can be done using any number of aftermarket options. Going over 1,000 horsepower also requires a few additional things to be done in order to handle that load.

“Over 1,000 hp, we’re going to put a nice girdle in the bottom end,” Strube says. “Closer to 1,500 hp, we’re going to oversize the main studs to 14mm. I haven’t done anything more than a 1,500 horsepower set up on an Duramax, yet. My personal truck is at 1,400-1,450 right now. The majority of the guys are looking for 650-750 horsepower and they’re just having fun. They’re not doing any strict competition.”

Whether you’re looking for fun or looking to win, the Duramax platform is certainly one to consider. The Duramax engine is can be built up to do just about anything you want. The only obstacle is your wallet.

This article courtesy of Engine Builder.