Chrysler was one of the first manufacturers to use a TPMS relearn procedure that does not require a tool or special process. Just drive the vehicle for a minimum of five minutes (10-minute minimum for some RAM trucks) at speeds above 15 mph. Easy? It can be a simple procedure. But the longer you work on cars, you know that when a manufacturer makes a system simple on the surface, it is more complicated to service.

GM and Ford TPMS systems use a relearn procedure that starts with putting the vehicle into a learning mode with button or ignition key actuation. During the relearn mode, the sensors are activated with a TPMS tool in a sequence. If the TPMS system receives the four signals and IDs, the relearn procedure is completed while stationary. The Chrysler auto relearn looks for frequently transmitted sensor IDs during the test drive.

In the service information, it says a 5- to 20-minute test drive above 15 mph is required to relearn the TPMS sensors on the vehicle.

Why 5 – to 20 – minutes? Simply, the antennas need to receive a specific number of signals from each sensor. During this time, it is possible they will receive signals at 433 MHz from other vehicles. Why a 20-minute limit? If it takes longer than 20-minutes, the auto-relearn procedure is stopped and is started again during the next key cycle.

Why 15 mph? At this speed, it triggers small accelerometers causing the sensors to transmit. If the antenna receives enough signals from the sensors on the vehicle, it turns the TPMS light off and clears active codes.

Is there A Better Way?

Wasting time on a 5- to 20-minute test drive to turn off the TPMS light is not very profitable. Letting the customer leave with the TPMS light on with the promise that it will go out, does not instill confidence. With the use of a TPMS tool, you can turn off the light and know that it will stay out.

With a dedicated TPMS tool, you can capture the sensor ID numbers and position on the vehicle. Using the OBDII connection, the tool can program the IDs and locations into the module. The tool can even check for codes and perform diagnostics.

Diagnostics

The key to diagnosing a Chrysler TPMS system is to know what modules handle the TPMS functions and where the antennas are located.

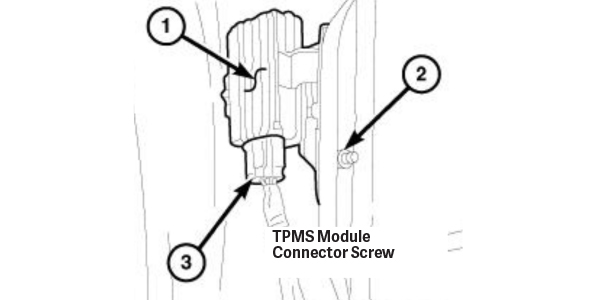

The base TPMS system consists of four or five sensors. The central receiver module Wireless Ignition Node (WIN) receives the signals. The module communicates with the instrument cluster and the TPMS light. The premium TPMS system consists of four sensors, a wireless control module (WIN) and three wheel sensor transponders located in three of the four wheel wells. Each sensor transmits tire pressure data approximately once every minute. Each sensor’s broadcast is uniquely coded so the Sentry Key Remote Entry Module (SKREEM) can monitor the state of each of the sensors on the four rotating road wheels.

Upon detection of a warning or fault condition, the WIN will send a request to the module that controls the indicator lamp (and the text display if equipped with the premium system) via the vehicle bus system to illuminate or flash the indicator lamp. Also, upon detection of a warning or fault condition, the electronic display will send a request to sound the “chime.” The WIN will store all warning and fault conditions, placard pressure values and low-pressure threshold values (lamp ON and OFF) in memory that can be accessed through diagnostic communication. If new sensors are introduced to the vehicle, the data stored for the sensor being replaced will be deleted.

The WIN will also store all wheel sensor IDs, locations and faults in its memory that can be accessed through diagnostic communication. All other data values transmitted from each active wheel sensor (not the spare tire) are stored in the WIN memory as well. After a sensor has been replaced, the WIN automatically learns and stores the sensor IDs while driving continuously above 15 mph (24 km/h) for 10 minutes. The learning sequence will initiate when the vehicle has been stopped for more than 20 minutes.

Article courtesy Brake & Front End.