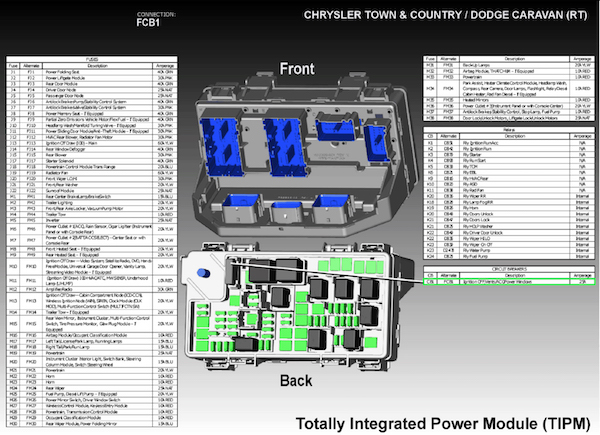

TIPM is a fuse box, relay box and electronic module all in one. The electronic module is connected to several data networks. For engineers, the module reduces a lot of wiring under the hood and passing through the firewall. The TIPM also increases the functionality of a component by allowing several inputs to control one component.

Think about something as simple as a horn. The horn honks when the driver hits the button in the center of the steering wheel, or it might honk as part of the anti-theft system.

Engineers could put a switch on the steering wheel along with the wiring through the steering column connecting to a relay and eventually the horn. For the anti-theft horn circuit, it would require a wire going from the anti-theft module to a relay and maybe a separate horn. But on a system with a TIPM, the circuit is simplified, and the physical inputs going from inside the vehicle turn into commands over a network from modules to the TIPM connected to a relay and component. This architecture can be used similarly for a fuel pump that requires several inputs from the ECM and anti-theft module to operate.

The symptoms of a failing TIPM can vary depending on the vehicle. On one car, it might be an inoperative horn or wipers. For other cars, it might be a no-start condition and erratic instrument cluster operation. A failure can be seen by a no crank condition.

But, a lot of common symptoms match the failure of a starter or fuel pump. You might end up throwing a lot of parts at a vehicle when the root cause might be the TIPM.

Triage

The most important part of a TIPM diagnosis is to interview the customer and then replicate the symptoms in the bay or on a test drive. The next most crucial step is to scan all the modules on the vehicle for codes.

The TIPM is on the CAN bus, so any issues with the communication between the ECM, ABS and BCM can cause problems with the TIPM.

Next, look at the module under the hood. Do not remove the TIPM – treat it like a crime scene. Inspect for any physical damage and water intrusion.

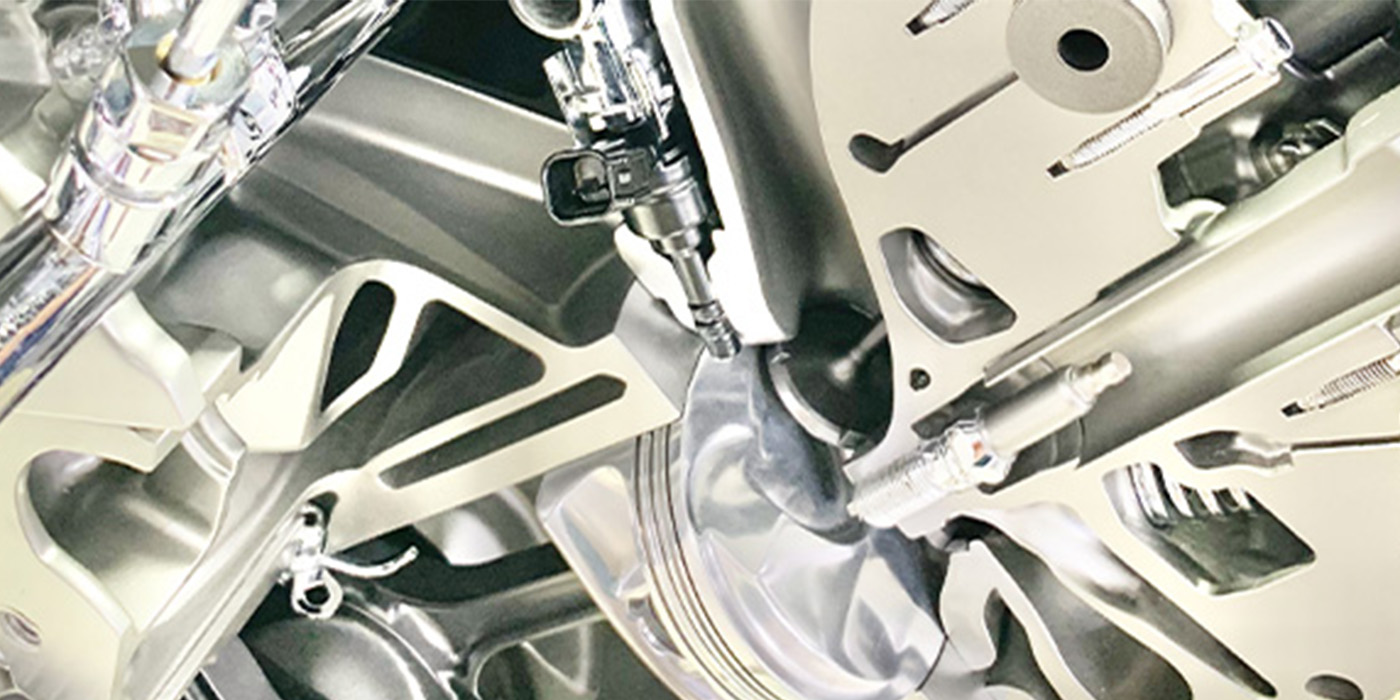

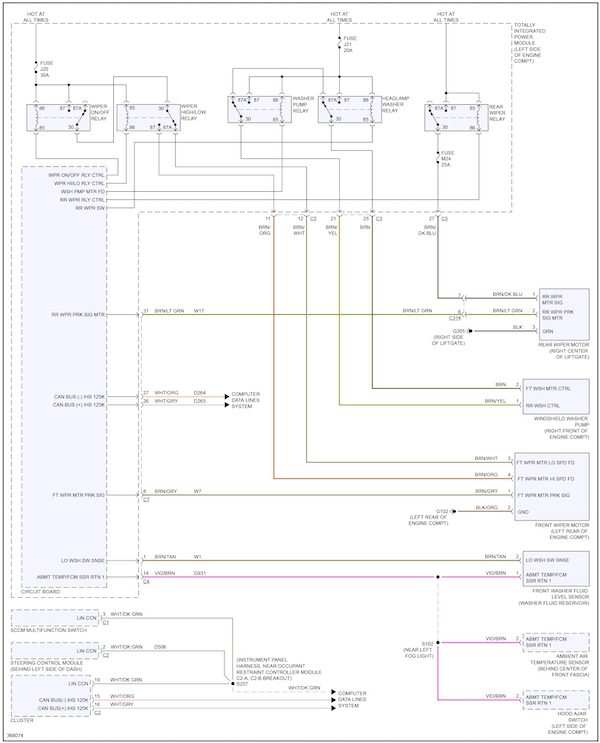

The first step is to determine if the inputs from switches and modules are present. For example, most wipers on Chryslers with a TIPM module have the relay that sends power to the motor. When the driver turns on the wipers, the Steering Control Module sends a signal to the TIPM using a serial data bus. The TIPM then sends a command signal to the wiper relay. If the wiper motor is working, the arms move.

The pathway for the actuation of the fuel pump and power windows are very similar. Before condemning the TIPM, it is critical to look at the circuit, controls and actuated component.

There are two ways a TIPM can fail. First, the TIPM’s electronic module can fail to operate and send out power to the control side of the relays. It can also lose the ability to communicate with other modules on the vehicle. When this happens, you might have codes in the TIPM and additional modules for loss of communication codes.

In these cases, use a scan tool to see the data stream change when a switch is pressed or when the key is turned. The data can be observed in both the module requesting the command and the TIPM. It is also critical to verify the operation of the component by powering the component with an external power source.

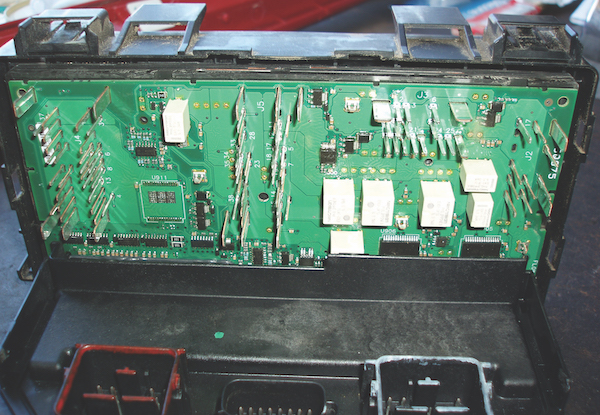

The TIPM contains the fuses and relays. Some of the relays are removable and can be tested for power and control. You can also confirm if there are good grounds.

There are other relays contained deep inside the TIPM. These are soldered to circuit boards, but these circuits have fuses for testing with an amp current probe. When these relays fail, it could require complete TIPM replacement.

Before you replace the TIPM, remove the unit and inspect the connections. If there is any damage to the connections and green crust around terminals, try cleaning the terminals. The problem might be resolved, but damage may have already occurred to the TIPM due to high resistance in the circuit.

But there are other strategies for TIPM repair besides replacement. If the fuel pump circuit has failed and the pump runs constantly, it is probably the fuel pump relay circuit. Some kits allow technicians to create a bypass around the relay in the TIPM. You can also attempt to solder a new relay on to the board.

If a TIPM needs to be replaced, there are several options today that were not around a decade ago. Aftermarket suppliers have new and remanufactured TIPM modules. Also, there are specialist rebuilders of TIPMs.

Article courtesy Underhood Service.