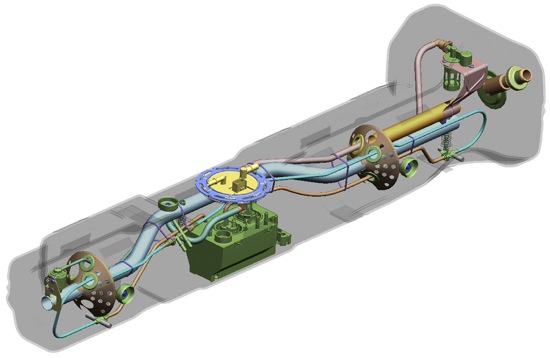

Fuel pump replacement comebacks can be costly and can hurt your reputation. One of the leading causes of failure is the tank. If a vehicle gets 20 miles to the gallon, then more than 5,000 gallons of gas (from many stations) will go through the tank in 100,000 miles.

And during this time, sediment, rust and debris from the pump can find its way into the tank.

Capturing Contaminates

Removing all contaminates is critical. If possible, have the tank steam-cleaned at a radiator shop that performs these services. They can recondition a tank and check for leaks that you may not be able to spot. Your goal in cleaning the tank is to restore the environment inside the tank to the same state it was in when they put fuel in before it drove off the assembly line.

If you think the new sock or strainer on the full pump will catch all of the bad stuff, you are wrong. The typical sock or strainer is designed to catch contaminates that are between 50-100 microns in diameter. Forty microns is the size of a human hair. A typical inline fuel filter can catch particles as small as 10 microns.

The sock also has a limited capacity due to its small surface area.

Always install a new filter. Sounds simple, but it is often forgotten. The old filter can restrict flow and make the new pump work harder. This makes for a hotter running pump that fails sooner.

When Fuel Can Become a Contaminate

Although cases involving contaminated gasoline are relatively rare nowadays, they still occur. In many cases, the technician has replaced the fuel pump or mass air flow (MAF) sensor to address a P0171/P0174 “lean-condition” DTC with no result.

In all likelihood, the technician didn’t consider the possibility that the vehicle’s fuel might be contaminated with E85 gasoline, diesel fuel, stale gasoline, or, to a lesser degree, sugar and water.

The fact is that the first three fuel contaminants tend to lean out the air/fuel mixtures, while sugar and water generally cause intermittent cranking, no-start and stalling complaints. In total, and depending upon the percentage present in the fuel tank, contaminated fuel can mimic the symptoms produced by defective fuel pumps, fuel injectors and fuel control components like MAF sensors.

E85 Gasoline

Although it’s hard to think of E85 gasoline as a fuel contaminant, it’s important to remember that E85 is designed for use only in flex-fuel vehicles. Because pure ethanol requires approximately 150% more volume to support stoichiometric combustion than does pure gasoline, some early flex-fuel vehicles use an ethanol sensor in the fuel line to estimate the volume of ethanol in the fuel.

Later flex-fuel vehicles simply use data inputs from their air/fuel ratio sensors to adjust fuel injector pulse width to accommodate increased volumes of ethanol. Most flex-fuel vehicles can be identified by an exterior flex-fuel emblem and, in many cases, a yellow gas cap.

Many motorists inadvertently top off their fuel with E85 because they are unaware that E85 gas pump nozzles are generally equipped with yellow covers.

Immediately afterward, they begin experiencing lean-fuel driveability symptoms such as hard starting and loss of power accompanied by a P0171 or P0174 DTC, depending upon the application.

At this point, let’s note that “ethanol” and “methanol” are distinctly different alcohol compounds. Methanol is used in racing applications because its high latent heat of vaporization keeps the engine cool, and because it produces slightly more horsepower than gasoline.

But, even with those advantages, methanol has a major tendency to corrode metal surfaces and degrade fuel hoses, O-rings and other soft fuel system components.

Additional Fuel System Diagnostics and Service

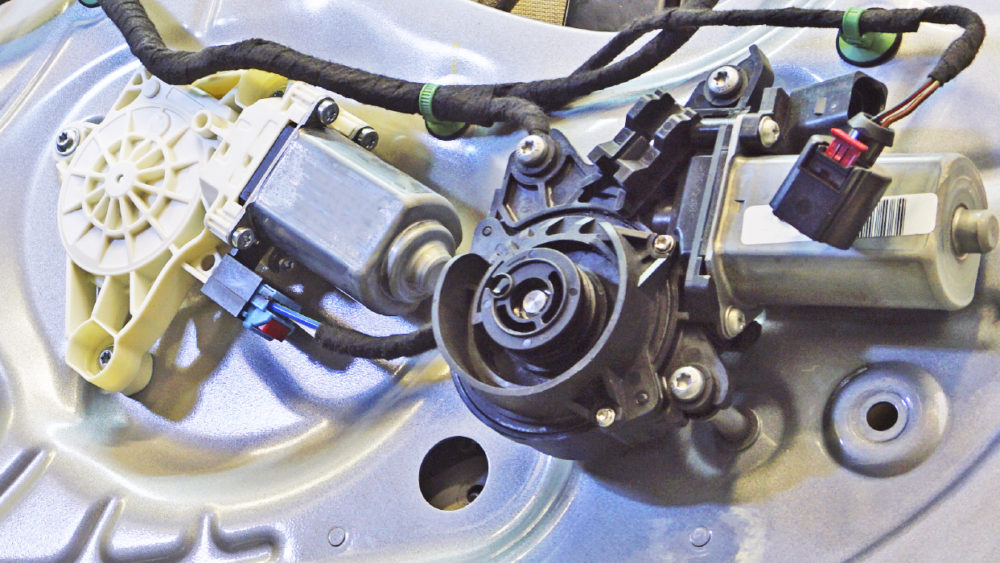

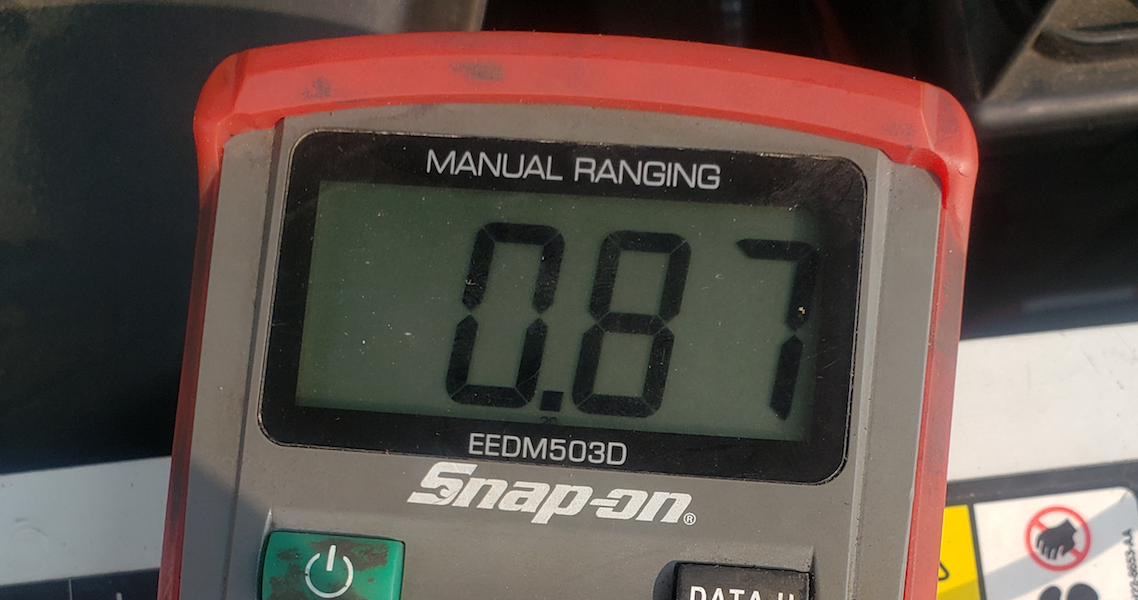

Bad grounds and connections can kill a new pump. Check the connector for any signs of thermal damage that may indicate there was a voltage drop or a circuit with high resistance. Do not assume the old pump caused the thermal damage. Bad grounds and circuits will stay with the vehicle and damage the new pump.

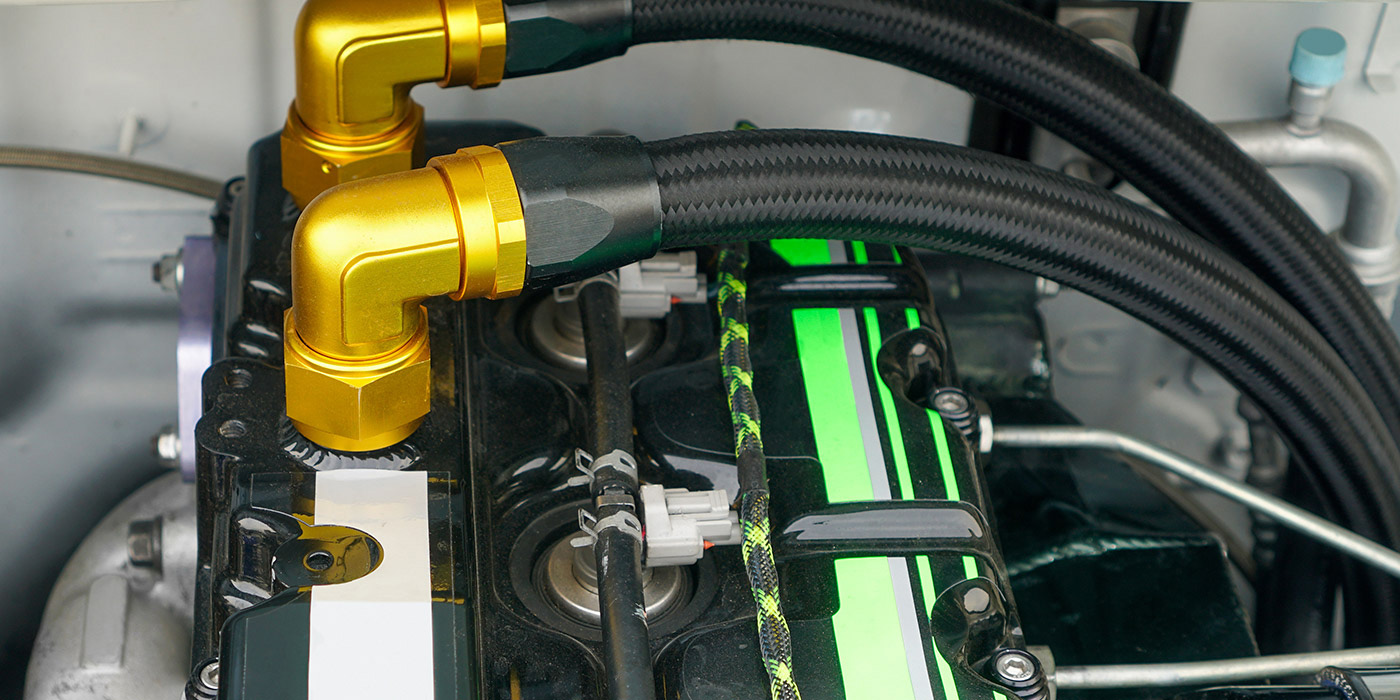

Filter the fuel before you put it back in the tank. If a fuel pump went through a full meltdown, chances are the pieces from the old pump are still in the removed fuel. Filter the fuel before it goes back in the tank. Many fuel caddies have built-in filters.

Check the EVAP system before returning the car to the customer. It takes at least one drive cycle for most vehicles to set an EVAP code. A leak due to disturbing the lines may not set a code during the initial test drive. The code may come on after the vehicle has been sitting for a while or a certain temperature has been reached.

Check the system with a scan tool and/or smoke machine before delivering the car to the customer. Some scan tools and vehicles can perform a self-leak check.

Fuel filler necks are especially susceptible to leaks if the tank has been dropped.

In the Rust Belt states, corrosion on the top of the tanks and on the fuel lines is starting to become a big headache during fuel pump replacement. This is due to brines being used on roads to prevent icing. Brines stick to vehicles — even the tops of fuel tanks — long after the snow storms have passed and even into summer. Then, every time it rains, the brines are reactivated and start to corrode the tank.

Also, check the straps and mounting hardware of the tank. In 2010, Ford recalled 1.2 million trucks due to corrosion of the straps that held in the gas tank.

Note: It’s a good practice to inspect the fuel lines for corrosion before starting the job. Nothing is worse than having to call the customer because a line collapsed due to corrosion during removal or installation.

Fuel Tank Cleaning Procedures

1. Once the tank has been removed, drain all fuel from the tank. Use only an approved container or a fuel caddy to filter and store the fuel.

2. Clean accumulated road debris or rust from the top of the fuel tank, especially around the module or hanger assembly to avoid contaminating the fuel tank.

3. Remove the lock ring.

4. Remove the module or hanger assembly.

5. Clean and flush the tank with water before installing the new module or hanger assembly.

6. Swish the fuel tank around in a circular motion to collect any debris remaining in the fuel tank.

7. Slowly and carefully poor the fuel out of the tank into the approved container or fuel caddy.

8. Turn the fuel tank over, then tap the bottom to remove any debris.

9. Clean the inside of fuel tank with dish soap and water. Modern fuel tanks are difficult to clean because of their internal baffling.

If a tank can be cleaned, it’s important to use high-pressure soap and water to remove the dirt. The tank should then be thoroughly dried by circulating air through the tank or by simply placing it in the summer sun. In many cases, a fuel tank replacement is the most cost-effective and safe alternative.

10. If possible, take a lint-free shop towel and wipe the inside of the fuel tank until it is clean.

11. Dry out the fuel tank completely with compressed air.

12. Inspect the fuel tank carefully. If the tank is rusted inside or shows signs of physical damage, it must be repaired or replaced.

13. After the tank has been dried with compressed air, let it sit for 30 minutes.