Diagnosing misfires and emission problems is getting more difficult on modern engines. Understanding what is going on inside the combustion chamber and what comes out the exhaust valve is critical to being able to solve any emissions or drivability problem.

Diagnosing misfires and emission problems is getting more difficult on modern engines. Understanding what is going on inside the combustion chamber and what comes out the exhaust valve is critical to being able to solve any emissions or drivability problem.

You must be able to understand what has happened and what will happen the moment the spark plug ignites the fuel. You must also know what the engineers were thinking when they were trying to create the perfect combustion event.

Compression Ratios

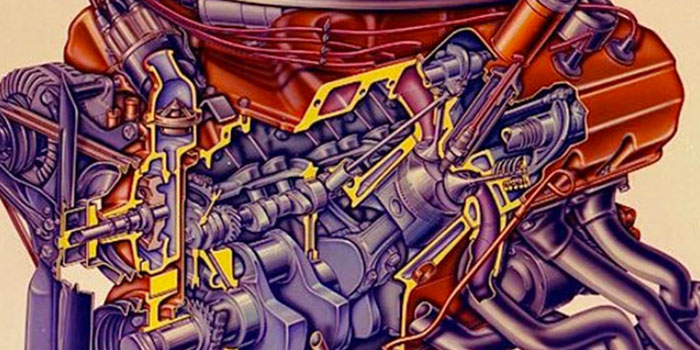

The internal combustion engine will never be perfect, but we are getting very close. Over the past 25 years, engines have advanced not only in terms of emissions, but power. We are seeing leaner combustion events that would have destroyed engines made less than a decade ago. This was made possible not with forged pistons or exotic materials, but by moving the fuel injector port into the cylinder and perfecting the combustion event.

The internal combustion engine will never be perfect, but we are getting very close. Over the past 25 years, engines have advanced not only in terms of emissions, but power. We are seeing leaner combustion events that would have destroyed engines made less than a decade ago. This was made possible not with forged pistons or exotic materials, but by moving the fuel injector port into the cylinder and perfecting the combustion event.

Just consider this: Some naturally aspirated engines for 2016 will have a 12:1 compression ratio. These are four-cylinder engines in everyday cars. In 1964, the 426 Chrysler HEMI had only a 10.25:1 compression ratio. A 1960s engine builder could build a HEMI with a 12:1 compression ratio engine, but it would be a slave to “race gas,” and there was always the possibility a malfunction with the carburetor, valvetrain or ignition system could destroy the engine in a heartbeat if it ran too lean and had a detonation problem. In a modern engine, 12:1 can be achieved with pump gas and cast pistons, all while having very low emissions and an 80,000-mile emissions warranty.

So what has changed? Engineers know more about what happens inside the combustion chamber than ever before thanks to high-speed cameras and computer models. Also, the computing speed of microprocessors is a lot faster than 15 years ago. The module can make changes to the spark and fuel faster while processing more sensor inputs than ever before. This evolution has made for the almost perfect combustion event.

So what has changed? Engineers know more about what happens inside the combustion chamber than ever before thanks to high-speed cameras and computer models. Also, the computing speed of microprocessors is a lot faster than 15 years ago. The module can make changes to the spark and fuel faster while processing more sensor inputs than ever before. This evolution has made for the almost perfect combustion event.

What is Perfect?

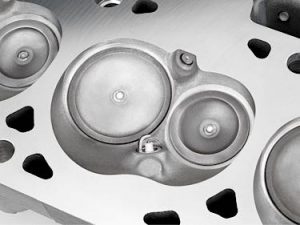

The perfect internal combustion vehicle would be able to put the exact amount of fuel and air into the combustion chamber. The spark kernel would reach its peak when the mixture was properly stirred up and the piston was in the right position. The flame front would spread evenly and would not have to fight turbulence.

If the perfect combustion event happened, you would get nothing more than water and carbon dioxide as a byproduct. There would not be any unburned fuel or oxygen. It would also occur at the right temperature so oxides (“hyperactive” oxygen turned on by higher temperatures) would not combine with nitrogen and carbon to form nitric oxides (NOx) and carbon monoxide (CO). This perfect car would not need any emission-control device.

We are not there yet. In the meantime, we have exhaust gas recirculation systems (EGR), secondary air injection and catalytic converters.

Spark Plugs

In theory, spark plugs have not changed in 100 years. In practice, they are one of the most evolved components in an engine. With today’s modern engines, the area where the spark is created is much smaller and finer part of the electrode while plug gaps are pretty much the same.

But, the big news is the placement and diameter of the modern spark plug as engines are reduced in size but have twice the complexity of 25 years ago.

Everybody complains about the spark plugs in the Ford 5.4 Triton V8 because they are difficult to remove. Very few people ask why they were put there in the first place. The spark plugs on the Triton are long and narrow, so the electrodes are perfectly placed near the exhaust and intake valves, and they are positioned to stay out of the way of the camshafts, valves and intake ports. Ford used a 12 mm plug with a thimble incorporting an electrode strap. The placement was determined with computer modeling to make sure the flame front spread evenly across the combustion chamber and burned all the fuel. This means that the catalytic convertor does not have to deal with the unburned hydrocarbons.

EGR Systems

EGR systems put a small amount of inert gas into the combustion chamber to control the temperatures. Since exhaust gases do not typically burn, this lowers the combustion temperature and reduces NOx emissions from the engine.

When things heat up in the combustion chamber to temperatures around 1,300° C or 2,500° F, oxygen and nitrogen start combining with each other and form NOx and CO.

By putting exhaust gases into the combustion chamber, the air/fuel mixture is watered down by the inert exhaust gases. This slows down the combustion process and lowers combustion temperatures to levels where NOx does not form.

Newer vehicles with variable valve timing on both exhaust and intake camshafts can adjust timing so that a small amount of exhaust gas is sucked back into the chamber during the intake stroke through the exhaust valves. This is done by actuating the timing and lift of the camshaft. Over the years, vehicles have been able to advance and retard camshafts faster, and the actuators have a greater degree of rotation.

Secondary Air Injection Systems

The problem with the perfect combustion event is that it has to occur over a wide range of engine and air temperatures. The modern engine still has a difficult time starting and controlling emissions under cold starts.

Secondary air injection systems pump outside air into the exhaust stream so unburned fuel can be burned. Early systems had a belt-driven air pump. Newer aspirated systems use the vacuum created by an exhaust pulse to pull air into the pipe. The latest systems use an electric motor to pump air. These systems are critical for the life of the catalytic converter.

Catalytic Converter

If an engine was able to achieve the perfect combustion event, you would not need a catalytic convertor. But, until this happens, these expensive emissions devices are mandatory. Under ideal conditions, a three-way catalyst can reduce somewhere between 50% and 95% of NOx emissions, and 99.9% of the unburned fuel. It is the last stop for pollutants, and if an emissions system upstream sensors are compromised, it can only compensate so much before tailpipe emissions increase.

Diagnostic Logic

To properly diagnose a high-emission vehicle, you must sometimes think like an engineer. Modern engines are able to operate on the ragged edge between detonation and ultimate fuel efficiency because they are able to sense, control and adapt.

The sensing part means that there are more sensors on the vehicle like upstream and downstream oxygen sensors. These sensors are more sensitive and can show a lot more resolution. Also, the modules processing the information are able to use the information quickly to map out fuel trims, spark curves and valve timing.

Controlling the combustion event has become easier with variable valve timing, electronic ignition and direct injection. These technologies ensure the correct air/fuel mixture is in the combustion chamber and ignited at the optimal time to achieve the most efficient and powerful combustion event.

Modern engines are also able to better adapt to conditions like changes in fuel quality, ambient temperature and driver demands by sensing and controlling the combustion event almost in real time.

The diagnostic “crutches” of swapping parts like spark plug wires, sensors and other components will not typically work and the customer will lose faith in you long before you get a second try. Gathering and analyzing data from the vehicle and from service publications has a lot more value than going off hunches.

Article courtesy Underhood Service.