Filters have long been a common maintenance item. But with longer factory service intervals and “lifetime” filters becoming more common, how often do filters really need to be replaced?

Filters have long been a common maintenance item. But with longer factory service intervals and “lifetime” filters becoming more common, how often do filters really need to be replaced?

There’s no simple answer. The safest advice used to be to follow the filter service interval recommendations in the vehicle owner’s manual (assuming the owner’s manual hasn’t been lost and that somebody will actually read it!).

The problem with this recommendation is that some filters no longer have a service interval (such as most fuel and transmission filters), and the factory recommended service intervals for some filters and fluids (motor oil and filter for example) may be overly optimistic and don’t take into account the kind of driving many motorists actually do.

A filter’s main purpose is to trap abrasive particles before they can do any harm. That’s true of air filters, oil filters, fuel filters and transmission filters.

As for cabin air filters, their purpose can be two-fold: to keep dirt and grit out of the HVAC system and passenger compartment, and to absorb and trap unpleasant odors before they enter the vehicle (in the case of dual-purpose cabin air filters).

All filters, even “lifetime” ones, have a limited service life and eventually become clogged with dirt, wear particles, rust and other debris.

So, the idea behind preventive maintenance is to change your customers’ filter before it reaches that point.

Air Quality Control

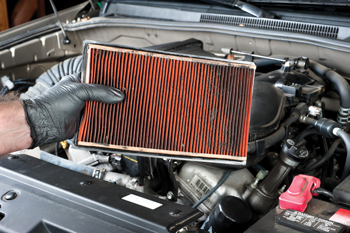

Air filters also have much longer replacement intervals these days — assuming the motorist is not driving in an extremely dusty environment or on rural gravel roads.

The typical factory-recommended service interval for many air filters these days is 30,000 to 50,000 miles. A realistic recommendation for air filter service on your customers’ vehicle is to inspect it at every oil change, and to replace it as needed, even if the factory service interval has not yet been reached.

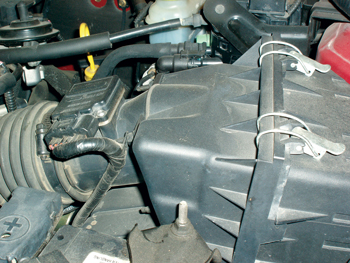

The difference in cross-sectional area decreases the velocity of intake air as it enters the air filter housing. This decrease in air velocity causes air-borne debris to fall out of the air to the bottom of the housing.

This change in air velocity increases the life of the air filter and tends to dampen the throaty resonance of air rushing into the engine. Last, and most important, this reduction in air velocity helps increase the accuracy of the MAF sensor by removing turbulence from the incoming air.

See Photo 1.

Unfortunately, many “tuner” or “hot-rod” technicians who replace OE systems with performance-aftermarket systems might not understand that modern MAF sensors basically measure the volume and density of the incoming air by measuring the change in current flowing through a resistor or wire as it is cooled by a smooth, non-turbulent flow of incoming air.

This operating principle provides the MAF sensor with the ability to precisely measure air flow in grams-per-second increments.

See Photo 2.

While space doesn’t allow for a full discussion of MAF diagnostics, it’s important to know that dirty MAF-sensing elements miscalculate the amount of air flowing into the engine, which results in an erratic air/fuel ratio calculation and a subsequently erroneous calculated engine load or calculated barometric pressure data value on a scan tool.

While space doesn’t allow for a full discussion of MAF diagnostics, it’s important to know that dirty MAF-sensing elements miscalculate the amount of air flowing into the engine, which results in an erratic air/fuel ratio calculation and a subsequently erroneous calculated engine load or calculated barometric pressure data value on a scan tool.

In most cases, miscalculations caused by dirt and air turbulence actually decrease, rather than increase, horsepower and fuel economy.

The fact that an air or fuel filter might remain in place for extended intervals should underline the importance of how we perform an air or fuel filter replacement.

All too often, an inexperienced person may actually damage the air filter housings when changing a filter. Others may slip an air filter in place without cleaning the air filter housing or sealing surfaces.

Needless to say, dirt leaking past an air filter for thousands of miles will not only shorten engine life, but will foul the MAF sensor, throttle plate and idle air control (IAC) systems with dirt. Even in an era of electronically controlled throttles, dirt accumulation around the throttle plate can change the base air flow enough to cause cold-start and idle speed control complaints.

When disassembling an air intake system, always inspect the inside of the downstream ducting for dirt contamination.

If dirt is evident, then dirt is leaking past the air filter into intake air chamber. Because dirt around the throttle plate can cause performance complaints, the throttle plate should be cleaned with an aerosol throttle plate cleaner.

Never use an aerosol carburetor or brake parts cleaner to clean a throttle body because those solvents might damage throttle shaft seals or peel delicate throttle bore coatings. An old toothbrush can be used to loosen hardened deposits.

See Photo 3.

Next, inspect the MAF sensor for dirt contamination. Although minor MAF sensor contamination can be cleaned with an aerosol MAF cleaner, remember that cleaning the MAF sensor usually won’t restore the MAF to 100-percent efficiency.

Because a cleaned MAF will probably be operating at a maximum of only 80-90-percent efficiency, a MAF replacement should be considered.

Next, lubricate neoprene hose fittings and duct attaching points with a light film of silicone or silicone grease to assist reassembly. Be sure to vacuum all debris out of the air filter housing and clean the sealing surfaces before reassembly. If the vehicle has a “snow screen” built into the air inlet, inspect and clean if necessary. Replace the housing if it’s damaged or distorted.

Fuel Filters

Fuel filter replacement intervals vary from between 20,000 miles to 150,000 miles, to “lifetime” in some applications.

Modern fuel quality is so good that many import manufacturers leave the replacement interval to the technicians’ discretion. In any case, it’s important to compare perception with reality in the modern air and fuel filter markets.

Scheduled fuel filter replacements are often ignored in the quick lube bays because they are more difficult and time-consuming to perform.

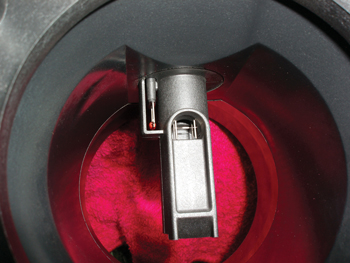

Many modern vehicles also have the fuel filter built into a “fuel pump module,” which eliminates the need for scheduled replacements. In any case, an excessive load is placed on the electric fuel pump as it struggles to pump fuel through a clogged fuel filter.

This is why many fuel pump manufacturers want new filters to be installed with their new fuel pumps.

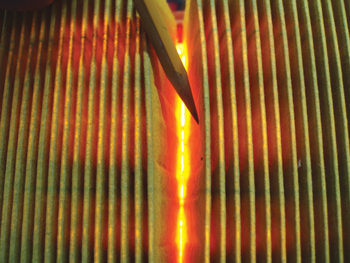

See Photo 4.

Note: For tank-mounted fuel filters, the filter should be replaced if the fuel pump is being replaced for any reason. New fuel pump modules usually come with a new filter as part of the assembly, but if you’re replacing the pump separately, you should also change the filter and pickup screen.

When reinstalling the fuel filter, make sure that the retaining bracket and fuel connections are firmly attached before starting the engine. Incorrect installation techniques can create a fire hazard liability if the fittings or hose attachments leak or become disconnected during normal driving.

Transmission Intercepted

Transmission filters should be changed if the transmission fluid is being replaced, if repairs are being made to the transmission, or if the transmission oil cooler or lines are being replaced to keep contaminants out of the transmission.

For dust-only cabin air filters, inspecting and replacing the filter every 15,000 to 30,000 miles is usually adequate, except for rural areas or dusty environments. For odor-absorbing cabin air filters, the service life is about a year before the carbon granules become saturated and lose their ability to remove odors.

Oil Filters – More than Mainstream ‘Media’

To many people, oil filters are a generic product. They look for the cheapest filter that fits their vehicle and make their buying decision based on price alone.

Oil filters do look pretty much the same on the outside, but what’s inside the can or cartridge (filter media) can make a big difference.

Filter manufacturers use a variety of different filter media to keep the oil clean. Resin impregnated paper filter media has been around forever and uses cellulose fibers to trap contaminants. A high-quality paper filter element with evenly spaced pleating can provide good filtering efficiency.

The typical OEM or standard replacement oil filter with cellulose fiber media will trap about 97.5 percent of most particles that are 15 to 40 microns in size or larger.

Some filters use a combination of cellulose fibers and non-woven plastic or synthetic fibers to improve filtering efficiency. The different materials may be combined together or used in a multi-layer filter element.

These types of filters can have filtering efficiencies as high as 99.5 percent and trap up to 40 percent more contaminants with particle sizes as small as 3 to 5 microns. Non-woven synthetic fleece fibers also are used in some filters to increase filtering efficiency and capacity.

One of the biggest challenges that all oil filters have to cope with today is longer service life. Though 3,000-mile oil changes are still recommended for severe service driving, OEM-recommended oil change intervals for “normal” driving today can range from 5,000 to 7,500 miles, or up to 10,000 miles or more.

Many vehicles don’t even have a recommended service interval and rely instead on a “Service Reminder Light” to estimate when the oil needs to be changed.

On some vehicles, the light may not come on for 12,000 to 15,000 miles depending on driving conditions! That’s a long time for an oil filter to remain in service.

The best advice you can give your customers is to buy the best oil filter that is listed for their engine — especially if they are not changing their oil for 7,500 miles or more.

Many premium filters can go 10,000 miles or more. In any event, extended oil service intervals of 10,000 miles or more require both synthetic motor oil and a premium quality filter.