This article is courtesy of Engine Builder.

COVID-19 made 2020 tough on all of us, but for Chad Lindsey of Legendary Diesel Performance, the pandemic wasn’t the only thing making last year more difficult. Just as the pandemic was taking hold in early 2020, Chad’s diesel shop caught fire, making the next five months especially hard.

“Basically, our chimney started a fire in our attic,” Lindsey says. “It burned a bunch of the trusses in the ceiling, so when [firefighters] pumped the water up there it compromised the structure, so they had to take the whole roof off the building and bring in a crane and put in all new trusses. It happened right at the beginning of winter, so we couldn’t work on the roof right after. We went all winter with a temporary structure to hold the building up, so we had very limited space to use in our building.”

The fire happened on a Friday night, and fortunately, Chad happened to stop by the shop at the right moment to see there was smoke coming out of the building.

“I went in to investigate and found that there were embers coming down from the ceiling,” he recalls. “We were very fortunate. We were able to get customer builds out before they actually started hosing things down. However, because they used roughly 2,500 gallons of water on our ceiling, it damaged our parts room where we keep our inventory, some of our tool boxes and stuff like that, but we didn’t lose anything customer-wise.”

Lindsey had good insurance to help with the cost of the damage, but having to wait nearly five months for a new roof while working in far less space than usual was a challenge. According to Chad, the chimney was not actually the culprit of the fire. It did start the flames, but it turned out the building’s insulation was installed too close to the chimney, and over time, that insulation dried out enough for it to start smoldering and catch fire.

“It was just an accident, Lindsey says. “It just happened at a really bad time and it was a time consuming process.”

By summer 2020, Legendary Diesel Performance was back up and at full strength. The diesel shop in Three Rivers, MI is 42,000 sq.-ft. with six employees who focus on light-, medium- and heavy-duty truck maintenance, repair and engine work. Chad himself comes from a family with a long history of diesel knowledge.

“My family owns a trucking company, so we did a lot of our own maintenance,” he says. “I grew up around heavy-duty diesels. My family has always had diesels, heavy-duty trucks and farm equipment. My dad, my uncles, my grandpa all did their own maintenance. My grandpa used to have two-stroke Detroit diesels and would rebuild them every 20,000-30,000 miles. My history got me into it.”

Chad took his early knowledge of diesel work with him to the University of Northwestern Ohio (UNOH) where he gained the skills to work in the field as a technician for dealerships. However, it wasn’t long before he transitioned his love for pulling trucks into a side gig, and the early days of Legendary Diesel were born.

“I had always liked pulling trucks because we used to pull our semis, so I started building my own pulling truck and pulling it in Work Stock classes and stuff like that,” Lindsey says. “Then, people started asking me who did this work for you? Or who put that together? I started doing the Legendary Diesel stuff on weekends and nights to help support my own habit cost-wise. It kind of just rolled into a business from there.”

Legendary Diesel officially became a business in 2009, and today, the shop does work on just about everything diesel. When it comes to their engine repair and performance work, however, that is primarily reserved for Duramax, Powerstroke and Cummins B series customers. Machine work is sent out to other local shops, but the actual building of transmissions and engines is all done in-house.

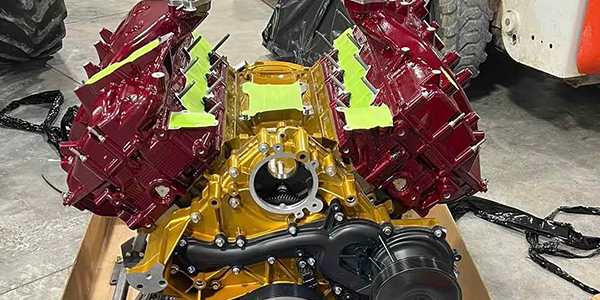

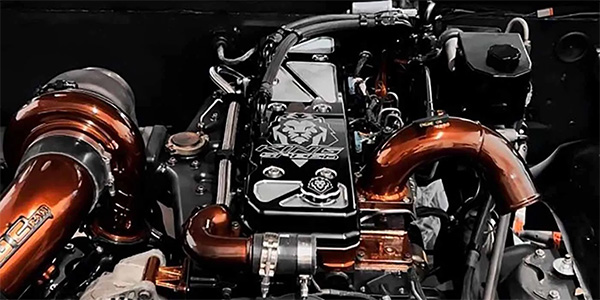

One such customer build was a sleeved 6.7L Cummins for a drag racing application that Lindsey said should be a pretty “healthy” build.

“It’s a sleeved 6.7L with custom Mahle pistons that are cut for valve reliefs and coated,” he says. “The rods are Monster Mike double I-beam rods. The engine also has a lightened and balanced crank and Mahle coated H-series bearings.

“The cylinder head is fire ringed and has Monster Pump Mike 13mm studs in it. The head also has a B&B side draft intake on it that got ported. We used Hamilton 110-lb. valve springs and a Keating Machine billet front cover. It’s got a Haisley Machine girdle in it with 13mm studs in the bottom end.

“It’s got a Stage 5 Colt camshaft with coated Colt Cam lifters. We also used Trend 7/16ths pushrods and Trend rockers and bridges. It’s also got a D&J billet valve cover, two 12mm S&S pumps on it and 400% over S&S injectors.”

According to Chad the 6.7L Cummins also adds a good deal of boost from nitrous, but also from twin Garrett turbos.

“The customer will probably run some nitrous on it, but it has twin Garrett turbos – an 88mm and a 103mm – those are Garrett NX turbos. One’s a Garrett 45 series and the other is a 55 series. It’s a pretty rowdy engine.”

The 6.7L is going in a 2006 Dodge regular cab for drag racing and in addition to the engine build, Legendary Diesel also built up a new SunCoast transmission for the truck.

“We are a SunCoast dealer, so we build with mostly SunCoast parts,” he says. “It’s got a Suncoast billet triple disc converter, a billet stator, a 38 spline billet input shaft, GPZ clutches, and a full manual valve body from SunCoast.”

All said and done, this “healthy” Cummins build should be more than ready to tackle a drag strip or two.

Diesel of the Week is sponsored by AMSOIL. If you have an engine you’d like to highlight in this series, please email Engine Builder Editor Greg Jones at [email protected].