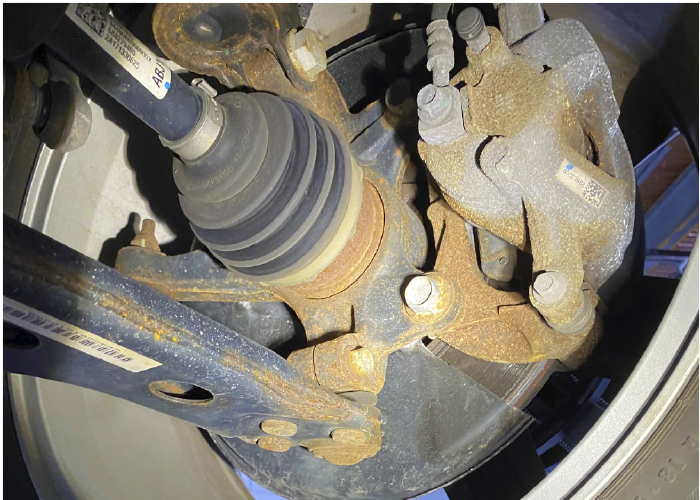

Complete replacement axles have become the industry standard, due to their ease of replacement and the availability of economy-priced axle assemblies in new and remanufactured forms. Like many automotive components, the “half-shaft” is made up of serviceable subassemblies.

When front-wheel drive became widely available in the 1980s, the aftermarket embraced service components for these axles. Boots, clamps, snap-rings and axle nuts have survived into the modern aftermarket, but the “guts” of the CV joint are long gone from ordering screens. Some companies still offer the balls, races, cages and housings to rebuild an individual CV joint but very few shops are interested in rebuilding a CV axle in the first place.

Complete replacement axles have become the industry standard, due to their ease of replacement and the availability of economy-priced axle assemblies in new and remanufactured forms.

Reman axles traditionally have been a popular stocking category, but more and more retailers are opting for new half-shaft assemblies. New CV axles also have the advantage of being built to the manufacturer’s specifications, rather than copying the OEM design. This allows a manufacturer to consolidate part numbers, redesign components to address known failure points or simply to offer a unique product to their customers. Catalog footnotes and pictures can help with identification of uncommon design issues, so be sure to look for those additional details.

Problem Children

For the most part, complete CV axle sales are a simple matter of cataloging the vehicle options and then choosing either left or right.

As with any component, there are always a few “problem children” – applications that leave the technician or parts specialist scratching their heads when the part in the box doesn’t match the part on the vehicle. One of the most common of these “mismatches” occurs with GM vehicles like the Malibu, Grand Am and other compact models. In a handful of cases each year, I encounter a customer looking to exchange a “misboxed” CV axle because the inner joint of the new axle has female splines, rather than the male stub on their original axle. The new female-splined axle is correct for these applications. However, the male stub shaft must be removed from the old axle and transferred to the new one. This short intermediate shaft is held in place with a circlip retaining ring at either end, and too often, the stub shaft comes out when removing the CV axle. Customers with Dodge/Ram 1500 trucks may experience similar “stuck stub” issues.

The issue with “missing parts” also may present itself when customers purchase a CV axle for various Saab models. These axles often are sold without the inboard joint, because of the labor involved in removing the inner joint from the transmission. It is common to find the exposed tripod and inner boot, with a clamp and packet of grease included in the box. Some Honda, Acura and Isuzu SUV applications also feature CV axles without the inboard joint, due to the fact that except for the inboard joint, the right and left side assemblies are identical. This is an example of consolidation of SKUs, not lack of quality control at the factory.

Whether new or remanufactured, complete CV axle assemblies can throw you and your customer a curveball from time to time. Obviously, it can be a bit of a disappointment to some customers when they discover that their CV repair just got a whole lot more complicated than they expected.

This article courtesy of Brake & Front End.