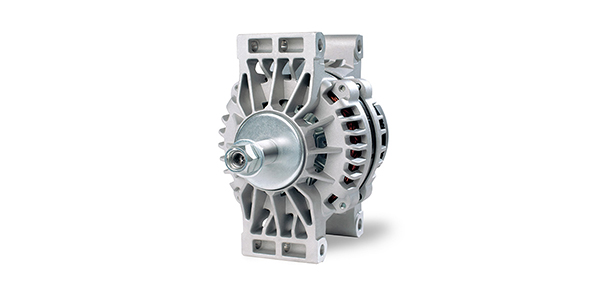

DENSO Products and Services Americas Inc., an affiliate of leading global mobility supplier DENSO Corp., has expanded its line of PowerEdge alternators by adding a value option to its 24PE series. The new model, the 24PE 160A, fills the heavy-duty aftermarket’s demand for a high-efficiency alternator at a more competitive price, according to DENSO.

“Different customers have different needs, and the heavy-duty replacement market was lacking a robust, quality alternator for a lower cost of ownership,” said Otto Jun, product manager of DENSO Heavy Duty Product Management. “We developed the 24PE 160A to fill the gap.”

The new 24PE series model is a 12-volt alternator that produces 160 amps at road speed and 100 amps at idle to meet and exceed the electrical demands of today’s Class 8 trucks. The 160-amp version leverages DENSO’s world-class engineering and craftmanship with its vast supply chain network to ensure all segments of the heavy-duty market have access to a superior product.

According to DENSO, advantages of the 24PE 160A alternator include:

• Unmatched quality, reliability and durability at a lower price point;

• Components and functionality tested under extreme conditions, including severe thermal temperatures, to ensure lasting OE-quality parts and performance;

• Lightweight and compact construction for ease of installation;

• Best-in-class air flow provided by dual internal fans to quickly lower temperatures under the hood under the harshest conditions;

• Available in both pad mount and J180 mount configurations; and

• All 24PE 160A alternators are 100% new with no core charge and backed by a one-year/unlimited miles warranty.

DENSO’s 24PE series alternators cover nearly all Class 8 trucks on the road today. For more information on all models, visit www.poweredgeproducts.com.