Do: Clean the Holes

To ensure accurate torque values and to avoid cracking the cylinder block, clean any dust, dirt, oil and fluid from the cylinder block head bolt holes before installing the new head gasket and head bolts. Never lubricate the head bolts with a friction-modified oil. Unless otherwise specified, lightly lubricate the bolt threads with 30w non-detergent motor oil.

To ensure accurate torque values and to avoid cracking the cylinder block, clean any dust, dirt, oil and fluid from the cylinder block head bolt holes before installing the new head gasket and head bolts. Never lubricate the head bolts with a friction-modified oil. Unless otherwise specified, lightly lubricate the bolt threads with 30w non-detergent motor oil.

Don’t: Clean with Non-Approved Tools

Rotary abrasives or wire wheels are not recommended for cleaning aluminum gasket surfaces. Not only can they gouge low spots in the cylinder head gasket surface, they also can contaminate the engine with highly damaging abrasive and wire filaments. Once lodged in the crankshaft bearings, these abrasive or hardened filaments will quickly ruin an engine’s crankshaft.

Do: Check for Codes

After warming the engine to full operating temperature and checking for oil and coolant leaks, connect your scan tool to check for pending oxygen sensor and other diagnostic trouble codes.

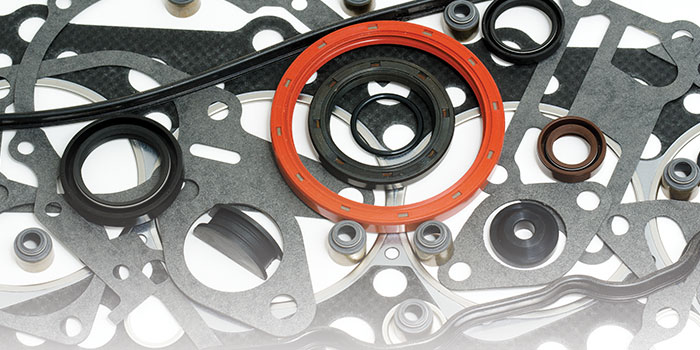

A head gasket job should not be approached with the mindset of “how cheap can it be done?” Instead, find the best way to efficiently repair the vehicle so the job will last, and deal with all possible issues that are somewhat related at the same time. Most jobs require head gaskets, a water pump, a timing belt, drive belts, thermostat, idler pulleys, a timing belt tensioner, tune-related parts and machine shop cost.

Do: Probe the Cooling System

The best way to check for an internal head gasket failure on a Subaru, for example, is to check for hydrocarbons in the cooling system. You can carefully insert the probe from your smog machine in the radiator (don’t let the coolant touch the probe). The reading will be more accurate with the engine fully warmed up. If the HC levels are above 10 ppm, the head gaskets are leaking internally into the cooling system.

Don’t: Do Only One Side

Even at some new car dealers, the policy might be to replace only the leaking bank of cylinders. If one head gasket failed though, chances are the other one will fail because it is connected to the same cooling system, same block and same engine management system.

Do: Look for TSBs on New Procedures and Specifications

Before you start a head gasket job, look at the TSBs for the vehicle. Often, the OEM will update procedures and parts once the vehicle has racked up some miles.

Don’t: Forget to Check the Engine When It Is Cold

Sealing problems are inherent in bi-metallic engines because aluminum cylinder heads expand faster than cast-iron cylinder blocks during the warm-up cycle. The difference in expansion rates is further aggravated because the cylinder head tends to heat up much faster than the cylinder block.

The difference in expansion rates between aluminum and cast iron creates a “scrubbing” effect that eventually wears out the stainless steel “fire ring” that keeps combustion gases from entering the cooling system. The cumulative effect of these repeated thermal events will result in failed cylinder head gaskets, so most aftermarket gasket manufacturers have designed head gaskets using space-age materials that resist scuffing wear in bi-metallic applications.

Do: Use the correct Fasteners and Procedures

Bolt breakage and uneven gasket loading or loss of torque can cause a newly installed head gasket to leak. TTY head bolts are designed for one-time use because they stretch permanently once they are torqued down. This helps even out the clamping force of the cylinder head on the head gasket.

But if the bolts are reused, stretching them even further greatly increases the risk of the bolt breaking. Some replacement head gaskets come with new TTY head bolts, but others do not. If an engine has conventional head bolts, it’s OK to reuse them – provided the bolts are in good condition and the bolts are not stretched.