There are many factors that must be considered in order for an internal combustion engine to run smoothly. As briefly described in my last column “Back to the Basics,” an engine needs to perform five crucial operations in order to run properly. Fuel, Spark, Air and Compression are all clearly important, but if they are not happening at the right time, the engine will not run. Ignition and valve timing are two variables that need to be accurate in order for the engine to run properly.

Ignition Timing

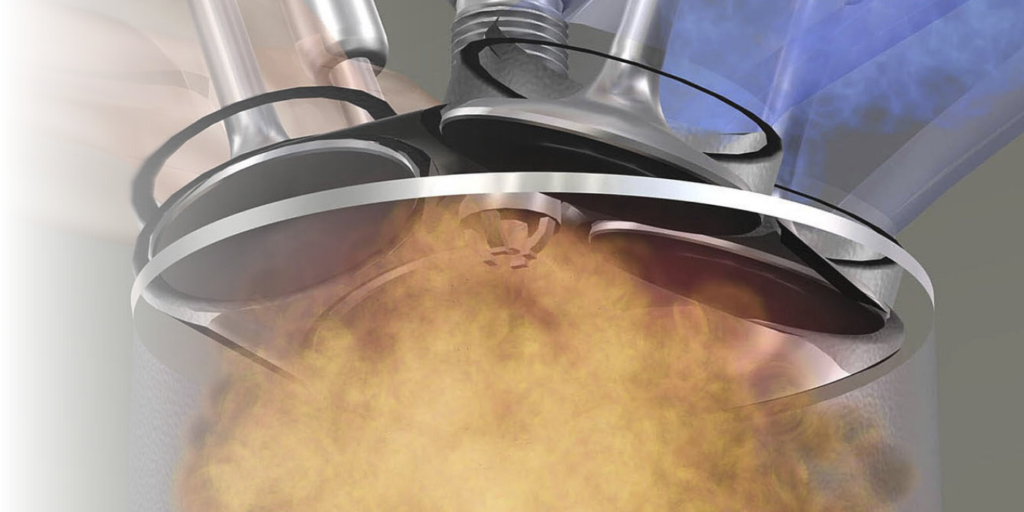

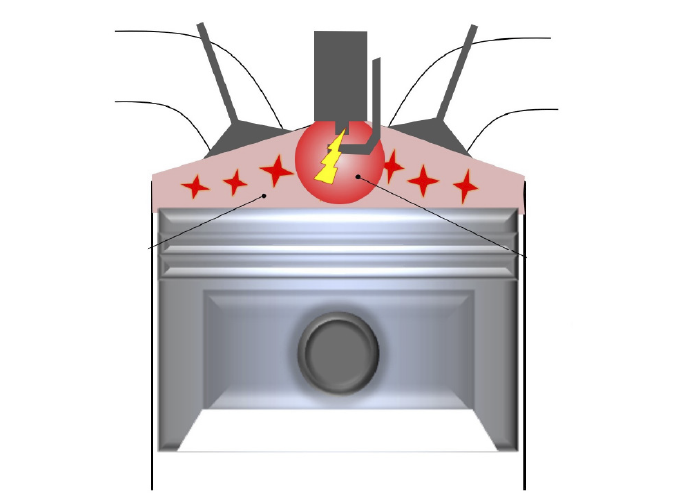

With a traditional internal combustion engine, ignition (spark) timing refers to the precise moment the spark plug needs to be fired in an effort to ignite the incoming air/fuel mixture for complete combustion. Among other variables, this calculation is based heavily on engine RPM. Because combustion does not take place instantaneously, the computer must fire the spark plug in ADVANCE, to ensure the power generated by the burning air/fuel mixture pushes down on the top of the piston at the precise moment. As RPM increases, so does the amount of advance (in degrees of crankshaft rotation). Confused yet?

Let me offer this analogy. In order for a quarterback to complete a pass to a running receiver, he must “lead the receiver” and throw the ball where he anticipates the receiver is going to be. Without throwing the ball in ADVANCE, he would never complete the pass. Your ignition timing is doing the same thing.

Depending on the speed of the engine (RPM), the computer must fire the spark plug in advance so the air/fuel mixture burns when the piston is in the proper position. Generally speaking, an engine will produce the most power if the ignition process begins at a point that allows the burn to be its fullest when the piston reaches 15 degrees after top dead center. In order to achieve this precise timing, the advance must increase as RPM increases. If spark ignition happens too early while the piston is on its way up during the compression stroke, combustion pressures will peak too soon, resulting in loss of power or even more severely, detonation. If spark ignition happens too late, the piston will already be too far down in the cylinder on the power stroke to effectively build enough pressure, again resulting in loss of power. Only when ignition timing is just right, will we maximize power output and achieve combustion efficiency.

Valve Timing

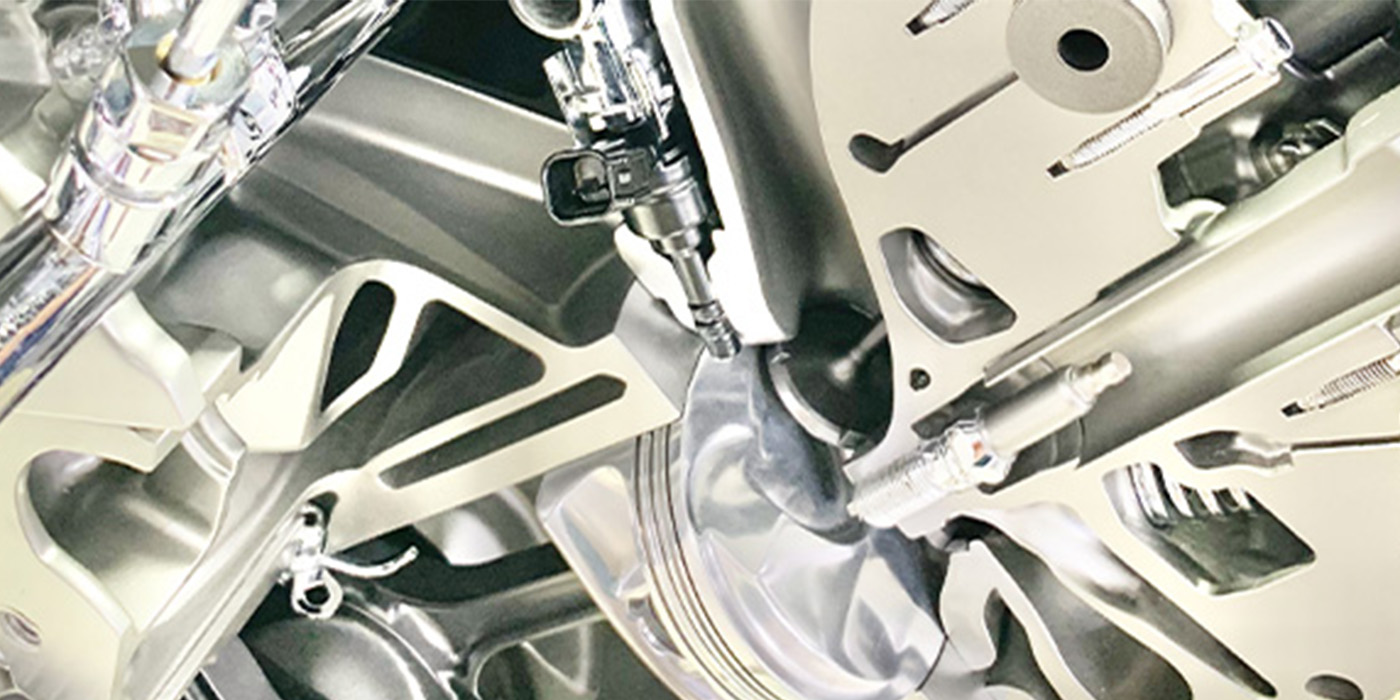

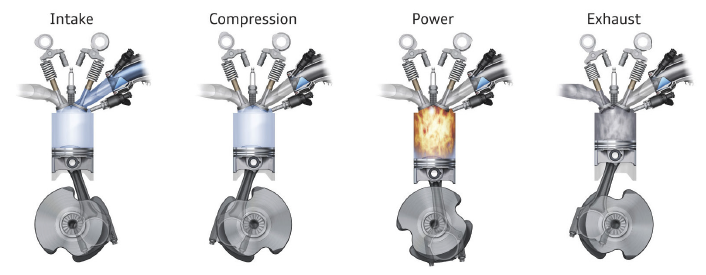

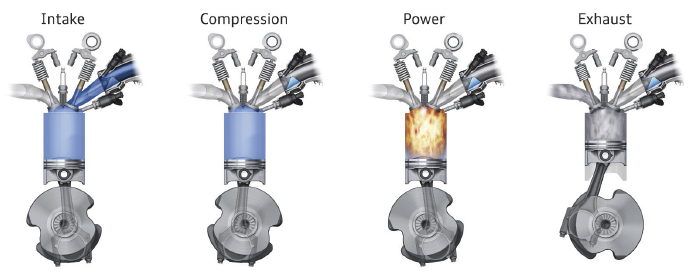

Just as spark timing is important for efficient combustion, valve timing is important for the engine to be able to inhale and exhale at the proper time. Valve timing refers to the precise timing of when the camshaft opens and closes the valves throughout the four-stroke cycle. This timing is based largely on the relationship between the position of the piston (degrees of crankshaft rotation) and the position of the camshaft intake and exhaust lobes.

This relationship is maintained by either a timing belt or chain. Its purpose is to allow the air/fuel mixture to enter (inhale) and exit (exhale) the combustion chamber at the precise time its needed. As an example, just as a marathon runner must control his or her breathing in a rhythmic pattern during a race, the engine must do the same. As the timing belt or chain rotates the camshaft, the lobes push down to open the valve. When the cam completes its rotation, the valve is released and begins to close from valve spring pressure.

Let’s look at the intake valve. If the valve opens too early (before the exhaust valve closes during the exhaust stroke), the full volume of air and fuel may not fill the combustion chamber, which could result in a loss of power. If the valve opens too late, the air/fuel mixture would be introduced into the combustion chamber as the piston is close to bottom dead center (BDC), which would minimize the amount of fuel in the combustion chamber, resulting in a loss of power. Turning our attention to the exhaust valve, if that opens too early, loss of compression and incomplete combustion could result. Open too late and there may not be enough time to “exhale,” leaving exhaust gas in the combustion chamber during the intake stroke.

When studied in depth, you will be able to see that there is a LOT of science involved in achieving proper timing; both valve and ignition. There are many variables that would need an entire book to cover. What we should take away from this article is that we should always consider timing as a potential area of concern when diagnosing misfires, detonation, loss of power, rough running engine or even a no start condition.

Please use this information as a springboard to further advance your understanding of some of the various types of timing an engine needs to operate effectively and efficiently.