Article courtesy ENGINE BUILDER.

When Dalton Russell got bit by the engine building bug, there was no stopping his transformation into a professional engine builder. Ever since wrenching on mud trucks, race cars, drag cars, and anything that made big power with his dad, to learning the ins and outs of engine building at the age of 14 from a local engine builder, Dalton has had horsepower dreams running through his mind. When he made the decision to attend SAM Tech, there was truly no going back – he would one day open his own shop.

“At the end of high school, at the age of 18, I knew this was what I wanted to do,” Russell says. “I wanted to open up my own shop, but as I was only assembling the engines and whatnot, I knew I needed more experience machining them and machine shops aren’t all that big on giving out free information.

“I had always watched the Engine Masters Challenge, and I always saw SAM Tech, but I never really knew what it was or I never really paid attention. Once I made the connection, I started looking into them and I ended up calling them and talking to them. I knew I had to go there, so I signed up right out of high school. I waited like three weeks and I was over in Houston at the school.”

Russell enrolled in SAM Tech’s block machining and cylinder head machining curriculum and made it his goal to spent as much time as possible there.

“I spent all day there just trying to learn everything,” Russell says. “About halfway through, I knew I was very serious about opening up my own shop. I started looking for machines and where I was going to do it and whatnot. I knew I was going to do it in my hometown of St. Augustine, FL because I already had a building lined up to do it.”

Dalton’s drive, passion and knowledge for engine building also caught the attention of several high-end shops looking to give him a job, but his desire to do his own thing was too strong.

“There were a couple job openings at some high-end shops that I was really, really considering taking, but I had to go with my gut,” he says. “I knew I wanted to open up my own shop. I went ahead and doubled down on that and I bought my first machine at PRI in 2018 and at that point I only had about six months left of school.

“I bought two other machines just a mile from the school, which was pretty crazy. On the last day of school, I was gathering up all my stuff to take everything home and I had three quarters of a machine shop sitting on my trailer out in the parking lot. It was pretty funny.”

Dalton officially opened Fathead Racing Engines in St. Augustine, FL in July 2019. He just recently celebrated a year in business and says things have been going very well.

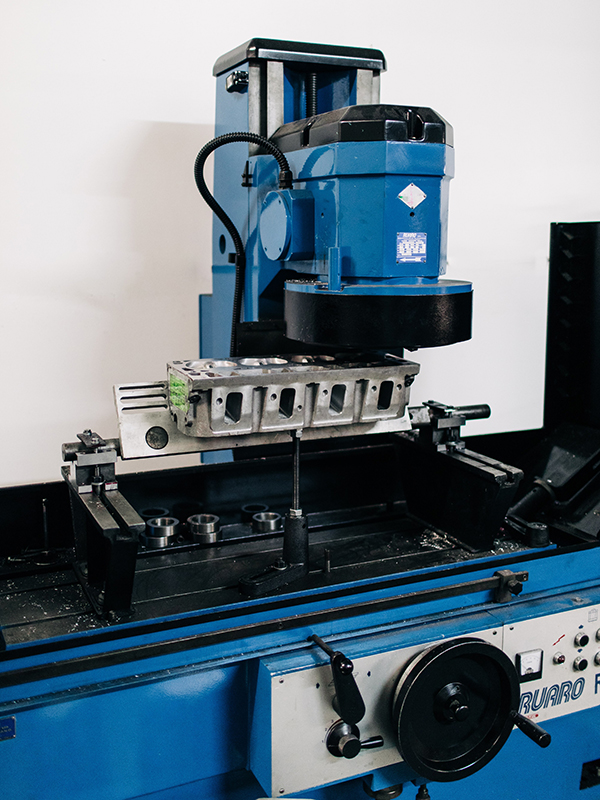

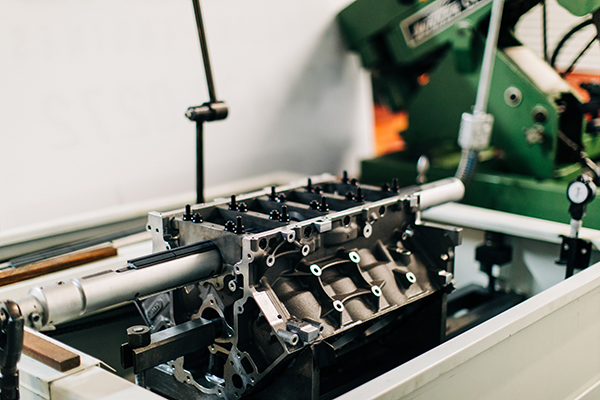

“It’s going really great. The shop is about 1,500 square feet,” he says. “I got a Rottler boring bar, a Sunnen CV616 hone, a CH100 line hone, a Storm Vulcan surfacer, and a jet washer to clean blocks with. I try to do everything block related in-house. I tried to start with the best equipment I could because that’s more important than anything. I still do send out my valve jobs on heads. I send those out to another machine shop close to me.”

Russell says Fathead Racing Engines is more focused on high performance and race engine builds, but he doesn’t turn away other engine work.

“We really do it all. I try to do everything I can,” he says. “However, 90% of everything we do is big block Chevys and LS nowadays. Those platforms are just really big right now and everyone’s using them.”

Case in point, Fathead Racing Engines recently had a customer come in with a 2000 F-body Firebird with an LS engine in it that the customer wanted to make more power with using a turbo kit.

“He had a couple of demands for it,” Russell says. “He wanted a turbo motor. He wanted pump gas. He wanted 700 wheel horsepower and it’s a stick car, so he wanted virtually no turbo lag. Immediately, we needed some cubic inches in the thing.

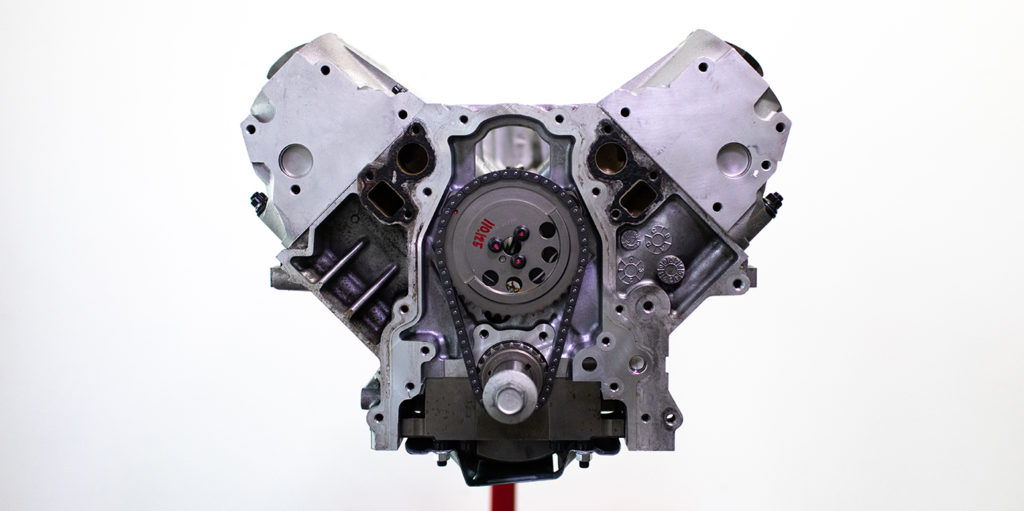

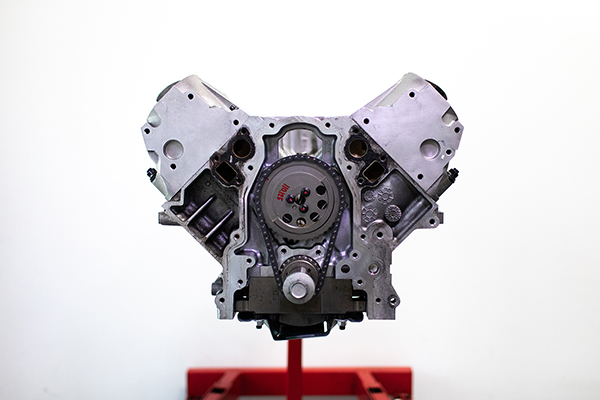

“I started putting the engine together with his LS1 block, which is not what I would prefer to use, but it’s what he had and what he wanted to use. I decided we’re going to do a 383 cid motor for him.”

The build began with the block getting jet washed and checked for cracks. The shop also made sure that the core hadn’t shift too bad in the sleeves. Once it got approved, it went on to the other machine work.

“We have a 3.905˝ bore in it,” he says. “Nowadays, pistons are getting better and rings are getting better, so it’s not just important to have a really straight and round cylinder anymore. You really have to have the right crosshatch in it. I used a step of four different stones to hone this thing and got a really nice hone job in it. We lined honed the block and surfaced it, so the pistons are right at zero deck. The bottom of the cylinders also needed to be stroker clearanced. We line honed it with ARP main studs. We fixed the housing bore up on it and ran ARP head studs.

“We used a Molnar 4.000˝ crank in it. We used Molnar Power Adder rods in it because we wanted him to grow with it. If he ever wanted to go to a stronger block, we wanted him to be able to use his rotating assembly in a better block and crank it up to 1,000 horsepower and it would be fine.

“We work real close with CP pistons, so we went with a CP piston on it. They have a really nice design. A lot of people worry about putting the 4.000˝ stroke in the LS – they say it pulls the piston too far out of the bottom of the bore – but CP has really nailed down a nice design on a piston and it makes that not a problem.

“We also work with Cam Motion a ton. They do all my custom cams. We did a custom cam for it – 236/232. We did that to try to keep the back pressure down because he’s running a fairly small turbo on it because he wanted to use the turbo kit he already had. We wanted to take that into account and we wanted the cam to really work well with it. That’s why we did the split like that. The turbo he’s running is a custom, VS Racing, 7875 billet wheel turbo.

“On the heads, we’re using a stock 799 head. My friend’s shop put a nice valve job on them and I blended the valve job and cleaned up a couple casting flaws. For his setup, he didn’t really need anything crazy. Because we’re only going to turn this motor at 7,200-7,300 rpm, we kept it with a stock rocker arm with a CHE trunnion upgrade. Aside from that, it’s running Cam Motion lifters, Cam Motion pushrods and Clevite H-series bearings.”

The finished 383 cid LS1 engine is going back in the customer’s Firebird and will be used as a street/strip car.

“We’re shooting to make 700 hp at the tire, and it should make that fairly easy on pretty low boost,” Russell says.

Engine Builder magazine’s Engine of the Week is sponsored by PennGrade Motor Oil and Elring – Das Original.