If you’re familiar with the Street Outlaws No Prep competition, chances are you’ve seen a 1988 Fox Body Mustang called Orange Crush. Driven by Chris Varni, Orange Crush features a 400 cid small block Ford engine under the hood built by Nick Dixon and the guys at Pro Street Engines in San Antonio, TX.

Nick first started building engines for Chris back in 2017, but has been involved in the engine building industry for quite some time.

“I was a teenager when I got introduced to a guy who was into drag boat racing,” Nick Dixon says. “I started working on the Top Alcohol Hydro drag boat. I was only 17-18 years old back then.”

The guys running the drag boat had ambitions to transition into Funny Car racing toward the end of the ‘90s. During that time, Nick wanted to learn and understand more about engine building.

“I was doing maintenance on the engine and I was helping put the engine together,” Dixon says. “I knew I wanted to work in a machine shop and learn more about engines and understand why we’re doing things the way we’re doing it and see how we can make more power. That was the mid-to-late ‘90s.

“In 1998, I started working for Kendrick Automotive, which was a machine shop and engine building shop. They’re not open anymore, but we started running Funny Car in ‘99. I left Kendrick’s and I went to work for Kotzur Racing Heads for a few years.”

Nick was working at Kotzur Racing Heads when 9/11 happened. It was shortly after that when he decided to join the Marine Corps.

“I was in the Marine Corps. for almost six years, and when I came back, I returned to Kotzur Racing Heads,” he says. “In the process of being there, I knew I wanted to open my own place. The oil fields started booming and I figured I could make a bunch of money there and open my own place up quicker. I worked in the oil field for a couple of years and that didn’t pan out. I left the oil field and opened up Pro Street Engines in 2015.”

Pro Street Engines just moved into a new, 5,000 sq.-ft. facility at the beginning of 2020 and focuses on building Modular Fords, Coyotes, LS and LT engines.

“We do get a few of the Hemis and four cylinders such as Mitsubishis and Hondas, but that’s not a big part of our market,” he says. “We mainly build the V8 late-model stuff. We still build small block and big block Fords and Chevrolets too. That’s a lot of our drag racing customers. We get a lot of street customers that are into the late-model stuff.”

In all, 99% of the work at Pro Street Engines is performance work. According to Nick, everything the shop has done these days has some type of power adder on it. And with so many performance engines going out the door, Pro Street Engines, and it’s three full-time employees, are set up to do machine work in-house.

One of Pro Street’s top customers is Chris Varni and his Orange Crush Mustang featuring a 400 cid turbocharged small block Ford.

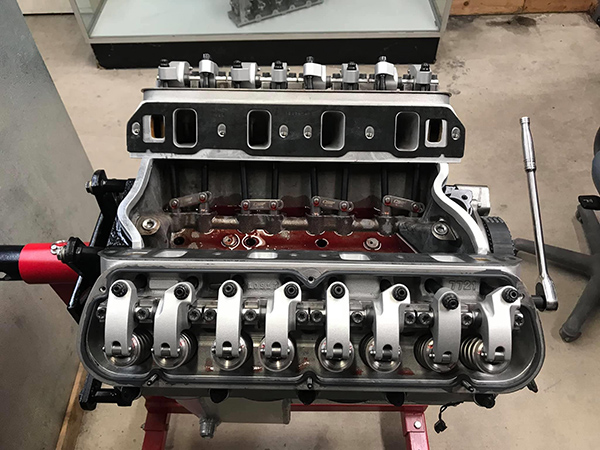

“He just finished filming for Street Outlaws out in Wyoming, and then he’s heading to Cash Days in about a week or two somewhere in Nebraska,” Dixon says. “Chris has been our customer since 2017. The small block Ford is 400 cid with a Sonny Bryant crank, GRP connecting rods, Diamond pistons, Total Seal rings, King bearings, a Dart block, a Danny Bee belt drive, and a COMP Cams 55mm solid roller camshaft.

“It’s got a wet sump external oil pump. We also run the Crane Ultra-Pro lifters, Trend pushrods and ARP hardware. It’s got an Edelbrock Victor head – it’s an inline head with a raised runner – it’s CNC ported. We’re using titanium intake valves and Inconel exhaust valves from REV. We run Manley Nextek springs, Jesel shaft-mount rocker arms and an Edelbrock single plane intake manifold.

“His whole turbo kit is built around that thing. It’s something I would really like to change on it though. That’s the only restriction on his set up right now is the intake manifold. It’s also got a big 98mm turbo from Precision. He’s still on gas. He runs VP race fuel. We’ve talked about switching over to methanol on the next combo, but I don’t know if we’re going to do that or not.”

The entire engine got all the machine work you would expect out of a 2,000-plus horsepower engine – line honed, square decked, bored and honed with torque plates, bored for larger cam bearings and the lifter bores, and CNC-ported heads.

“Nothing’s really standard when it comes to performance engines, but it’s standard stuff for us,” Dixon says. “We do the same thing on almost every engine, whether it’s a 500 horsepower build or a 3,000 horsepower build. I would say half the engines I get in from other engine builders, they’ll deburr the bottoms of the cylinders and the other half won’t. When that piston rocks over, it’s going to dig into that sharp edge.

“The other thing that’s overlooked by almost all engine builders are the lifter bores. Lifter bores have got a really sharp edge on them. If you don’t go in there and deburr that stuff, then the lifter is going to dig into one side or the other whenever the engine rotates over.”

With this 400 cid small block Ford all put together, Nick says it makes in excess of 2,000 horsepower.

“As far as times go, he runs well below 5 seconds in the 1/8th-mile,” he says. “He’s making over 2,000 horsepower on this thing. His car hooks and goes down to the track. It’s ridiculous how fast it is.”

Engine Builder magazine’s Engine of the Week is sponsored by PennGrade Motor Oil and Elring – Das Original.