Article courtesy ENGINE BUILDER.

Since the early ’90s, Brice Conner has been building race engines and immersing himself in the industry. His business partner, Levi Godsey, has done the same on the racing/driving side of things, and together they started Blue Chip Technologies Inc. and Blue Chip Racing Engines in Heltonville, Indiana, in 2017.

Between the company’s three buildings, Blue Chip Technologies has 30,000 sq.-ft. of space. Recently, getting everything on the engine building side under one roof has been their ultimate goal. The shop specializes in industrial machining, fabricating and performance engine building.

Blue Chip has both an engine dyno and a Dyno Jet chassis dyno, a Centroid 5-axis CNC machining center for blocks and head work, a Rottler diamond hone, a valve seat and guide machine, cleaning equipment, and dedicated spaces for both engine tear down and engine assembly.

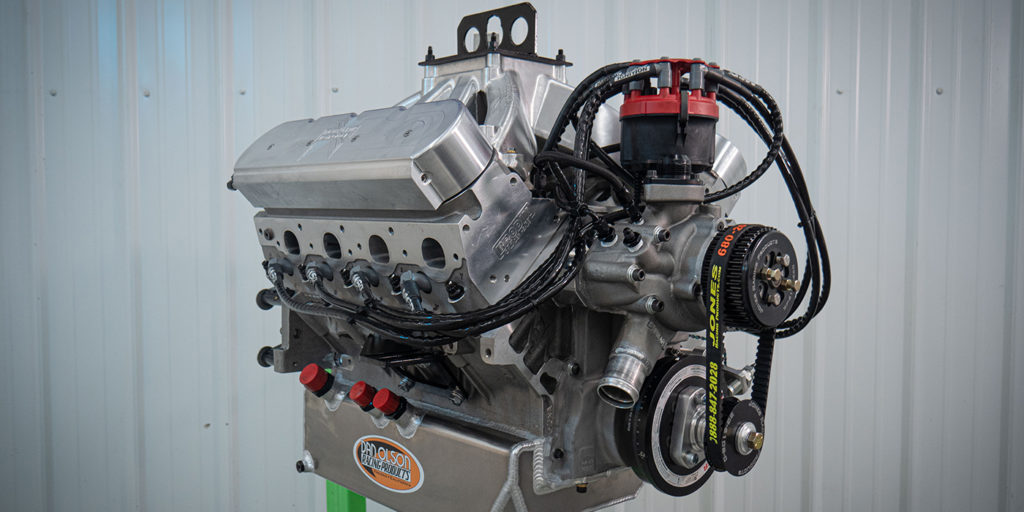

Blue Chip Racing Engines supports many local racers and sponsors its local dirt track. The shop builds high-performance engines for super late models, UMP modifieds, super stocks, crate cars, and pure stocks, but one of its more popular engines is its dirt late model engine package – a 434 cid LS engine build.

The dirt late model LS build starts with a Dart Next aluminum LS block, steel connecting rods, a billet crankshaft, custom Diamond pistons, a custom COMP camshaft, and is topped with Brodix cylinder heads.

“When it comes to the Brodix heads, we cut our port size and combustion chambers and use Del West titanium valves that were made to our specifications, as well as titanium locks, retainers and springs from Joe Hornick,” says Brice Conner. “We also use T&D stainless steel shaft-mounted rockers.”

With this particular engine package, Blue Chip was unable to find valve covers that they liked and that would fit properly, so they made their own.

“With our rocker arm ratio sometimes wanting to rub the covers, we decided to design and cut out our own billet valve covers from 6061 aluminum,” Conner says. “We gun drilled holes through the covers and drilled valve spring oiler nozzles into the covers with a .023˝ orifice.”

The 434 cid dirt late model LS engine has all kinds of goodies for racers, including offering up nearly 900 horsepower and over 700 ft.-lbs. of torque.

Engine of the Week is sponsored by PennGrade Motor Oil, Elring – Das Original and Scat Crankshafts.