Article courtesy ENGINE BUILDER.

When news came of Toyota bringing back its Supra sports car, a number of folks were pretty excited for its rebirth. However, you’d be hard-pressed to find someone more excited than Stephan Papadakis of Papadakis Racing. His shop was chomping at the bit to turn an already impressive car into something much more substantial under the hood and in the chassis.

Papadakis Racing, located in Carson, California, began drifting in 2004 and is the most winning team in Formula DRIFT history, earning the 2015 title with driver Fredric Aasbo, as well as back-to-back championship titles with driver Tanner Foust in 2007 and 2008. Team owner and engine builder Stephan Papadakis is a legend of sport compact racing who began building his reputation in the 1990s with the first front-wheel drive, tube-chassis drag car in the U.S.

The team has earned multiple records and championships in the discipline, turning in elapsed times and trap speeds previously thought unattainable in front-drive drag cars. Papadakis’ successes in front-wheel drive were matched by his efforts in rear-wheel drive when he campaigned a Honda Civic that became just the fifth car to join the NHRA’s Sport Compact 200 mph club.

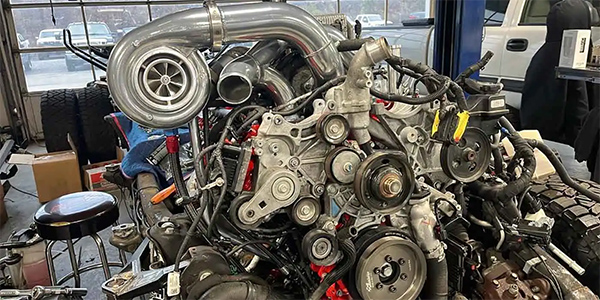

When Toyota announced the return of the Supra sports car nameplate to the model lineup, Papadakis Racing was one of the first to modify the Supra’s 2988cc B58 inline six-cylinder engine for racing, specifically for Formula DRIFT.

The stout B58 powerplant produces 382 hp and 368 lb.-ft. of torque from the factory, and when combined with the all-new GR Supra platform, the package gave the team a solid foundation for a formidable drift racer. Focused on pushing the new engine’s performance limits, the team tore down the engine, reworked the head with help from Port Flow Design, and added a package of competition-level components with an eye on increasing performance without sacrificing reliability to the tune of 1,000 horsepower.

Toyota itself debuted a number of vehicles at last week’s SEMA360, one of which was the Papadakis Racing Rockstar Energy Drink Toyota GR Supra that now competes in the 2020 Formula DRIFT Pro class with champion driver Fredric Aasbo. Here’s what went into the Supra’s transformation under the hood.

Wanting to make at least 1,000 horsepower, Stephan Papadakis started by tearing down the factory Supra engine to see what he had to work with.

“Once we stripped the engine down to the block, you could see that there were only two exhaust ports, but it’s a six-cylinder engine,” Papadakis says in his video of the build. “What they’ve done is there’s actually an internal exhaust manifold, but I do like the elegance of the turbo bolting straight to the cylinder head. The engine also has a drive-by-wire throttle body, and inside is where the intercooler is. It’s actually a water-to-air heat exchanger.

“Next, we pulled off the intake manifold, which is all plastic. The ignition system is direct coil on plug. For the direct injection, all the fuel injectors are actually not in the ports. Rather, they go directly to the combustion chamber. Because the direct injection runs at such high pressure – thousands of psi – you need a mechanical fuel pump to make those pressures.”

Papadakis also found that the Supra engine had an aluminum oil pan, and it doesn’t use gaskets. There’s actually very few gaskets on the entire engine. Toyota choose to use silicone to seal it up.

“The Supra engine is a DOHC engine,” Papadakis points out. “The exhaust side uses a variable lift camshaft set up. It still uses a camshaft, but it has two separate rocker arms and it has an eccentric shaft that changes the rocker ratio. Typically, the computer controls this depending on the throttle position and the load. For this build, we’re locking the system out for maximum lift. It uses hydraulic lifters and roller rockers.”

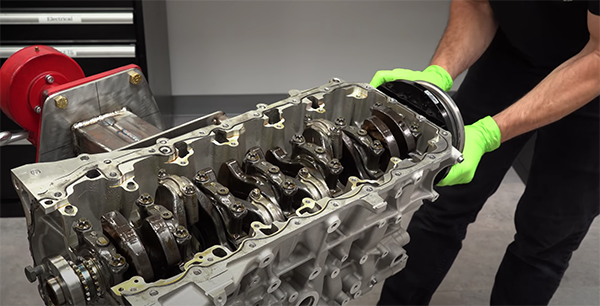

With the cylinder head off, Stephan could tell that this was a solid-deck block because he could see holes for the water, but it’s not an open water jacket. This style of block is very strong, so this engine has tons of potential.

“This is definitely a solid race block,” he says. “One of the big questions is if it’s a worthy successor to the 2JZ engine? And, did Toyota get it right by partnering with BMW for this whole project. I know I’m pretty impressed.”

Another thing Stephan liked about the Supra block is the oiling system. There’s a bunch of oil that has to go up to the head and it has to get back to the oiling system. The way they designed it was they didn’t want that oil to end up on the crankshaft and create a bunch of windage, so the oil comes down side ports and ends up underneath the windage tray and goes straight into the pan.

“During teardown, I also noticed the rods had a cracked rod cap, but that was by design,” he says. “It also has a coated rod bearing. The pistons are really modern. They are pocketed to reserve weight, and it uses a full floating pin and has a coated skirt as well. The crank is a forged steel crankshaft, which looks relatively stout and should hold at least 1,000 horsepower.”

Now that Papadakis Racing knew what it was working with, Stephan got to work on the areas the shop planned to make upgrades for performance.

“Our goal is to take this 335 hp 2020 Supra engine and modify it to make 1,000 horsepower on the engine dyno,” Papadakis says. “We’re looking for seven parts air to one part E85 ethanol fuel. The factory fuel system does support good power, but not enough for 1,000 horsepower. We installed six, 2,000cc fuel injectors. We also designed a completely new intake manifold that doesn’t have the water-to-air intercooler. We mounted a traditional air-to-air intercooler, which Mountune helped with the design of. That component got 3D-printed out of aluminum.”

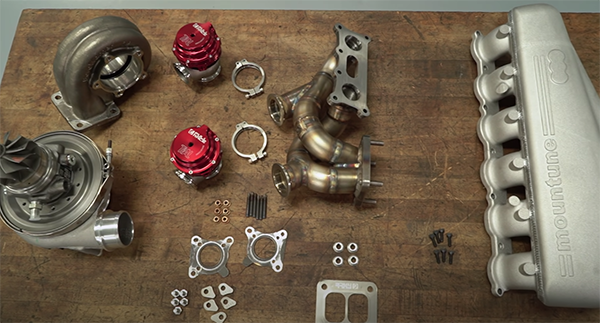

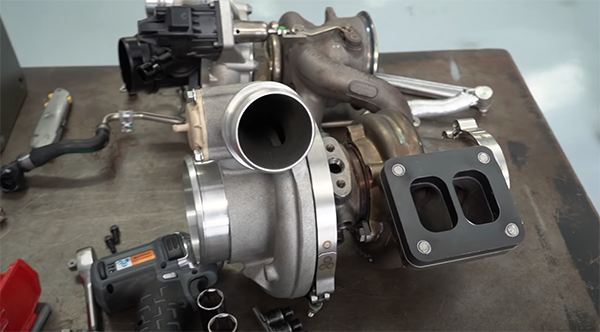

Another area Papadakis focused on was the turbo set up. The factory turbo will definitely make more than 335 horsepower, but it doesn’t have enough airflow to make 1,000 horsepower.

“We went with the BorgWarner EFR 9280 turbocharger,” he says. “It’s much larger than the factory turbocharger physically, and it flows much more air. However, that’s at the expense of some low rpm torque. For our racing application – Formula DRIFT – we’re ok with that. We don’t spend much time under 3,500 rpm.

“To mount the new turbocharger, we had to make a new turbo manifold with the help of Full Race. We choose a compression ratio of 11:1. We installed custom, forged pistons from JE Pistons, which also got a top coating and skirt for heat and wear resistance. We also designed these pistons to work with the factory Supra piston rings.

“Although the factory connecting rods do look beefy, we weren’t sure they could handle 1,000 horsepower. I didn’t want to find out what the limit is, because if you break a connecting rod, it’s usually a catastrophic failure. We went with a new, custom set of Carrillo rods. They’re made from a 4330M pre-hardened chromoly steel.”

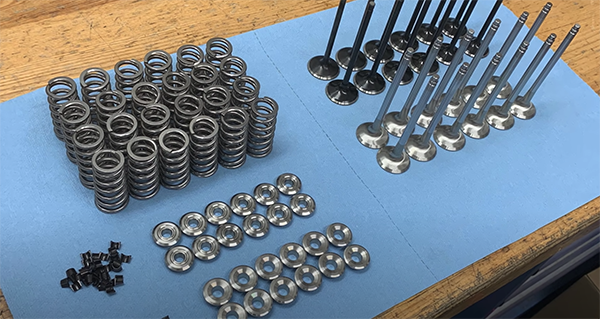

In addition to making the engine strong enough to handle the power Papadakis Racing wanted to make, the shop also needed to make sure the engine could breathe as efficiently as possible. Stephan took the cylinder head to Port Flow Design to get tested, ported and blended. With those areas of the engine enhanced, the B58 inline six-cylinder was ready for reassembly.

“We cleaned the block, and since everything was so new and in good shape, we also used the factory bearings to begin reassembly,” Papadakis says. “We stuck with the factory bore and hone. We just replaced the rods and pistons. We used ARP bolts. The cylinder head has Kelford cams and SuperTech valves, springs, retainers and keepers, and it should handle the power we are aiming to make.

“The engine’s valve cover started off black and is made of plastic. I wanted to do something trick, so we found this thing called ceracoat, which is like powder coating, but it can be done on plastic. We went with a bright red.

“The stock intake manifold had an intercooler built inside of it, but we don’t want to use it there. We want to use a traditional front-mount intercooler and port injectors, so we designed a special aluminum intake with the help of Mountune and got it 3D-printed. We then re-installed the stock throttle body. Full Race helped with the exhaust header and turbo set up. On this set up, we’re running dual external TiAL Sport MV-R 44mm wastegates.”

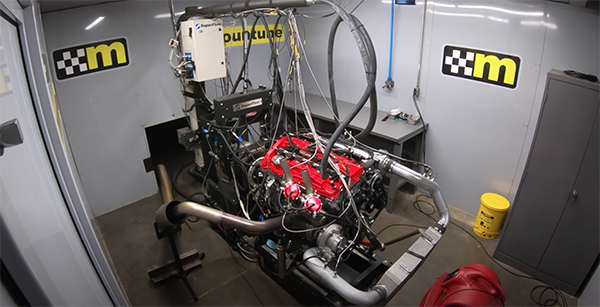

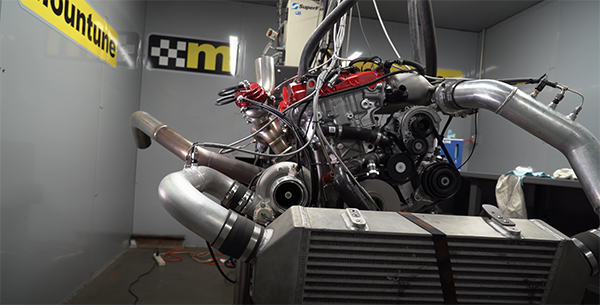

Papadakis Racing took the newly assembled Supra engine to Mountune in Carson, CA for dyno testing on their Super Flow dyno. Because they’re running a standalone engine management system – the AEM Infinity – instead of the factory computer, they designed an entire harness for it. This system runs everything for ignition, boost, injectors and tuning.

“After the first day of testing, we hit 850 horsepower,” he says. “To keep the set up simple, we didn’t use the direct injection, and instead just used port injection. What we learned was when you don’t send fuel through the direct injector, the tip can overheat. We ended up burning up an injector and compression was shooting out of the open whole.

“To remedy the situation, I machined some dowels to press into the holes where the direct injection enters the combustion chamber. We got the engine back on the dyno and got the boost up to 42 psi. In the end, the engine made 1,033 horsepower and 908 lb.-ft. of torque.”

Of course, Papadakis Racing did a bunch more work to the No. 151 GR Supra outside of the engine, but they got it up and running for the 2020 Formula DRIFT season. In fact, driver Fredric Aasbo put the car on the top of the box in its competition debut at the 2020 season opener and is currently in contention for the championship title. The season finale will be held November 20-22 in Irwindale, California.

Engine of the Week is sponsored by PennGrade Motor Oil, Elring – Das Original and Scat Crankshafts.