Article courtesy ENGINE BUILDER.

It used to be you met your perfect match in a bar. Today, most folks meet using an online dating app. But, if you’re a gear head, you might find your future partner at a car meet. That was the case for Nicole and Schiller Murphy, owners of iCraveBoost Performance in Denver. The husband and wife team met nine years ago and have shared a love for Mitsubishi Evos ever since.

“I had a 2005 Evo VIII and Nicole and I were always taking it apart, doing research and trying to figure out ways to make it quicker,” Schiller Murphy says. “Over the course of those nine years, we started developing our skills more and more and started working out of the garage. Once we were able to buy a house and have a little bit of extra garage space at our home that we live at now, we started taking in more jobs and refining our skills, buying more tools and equipment. From there, it turned into a bigger deal where we opened the shop in a central location in Denver.”

While the Murphy’s have been in the industry for quite some time, iCraveBoost Performance has been open for just two years under that name, and the shop’s Denver location has been open for nine months. However, don’t let that fool you – iCraveBoost offers a wide range of engine work and is primarily focused on 4G63s and Mitsubishi platforms from DSMs to Evo Xs.

“We also work on domestic LS stuff and Coyote stuff, Subarus, SR20s, RBs, 2JZs – those families of engines as well,” Schiller says. “But the 4G stuff is our claim to fame.”

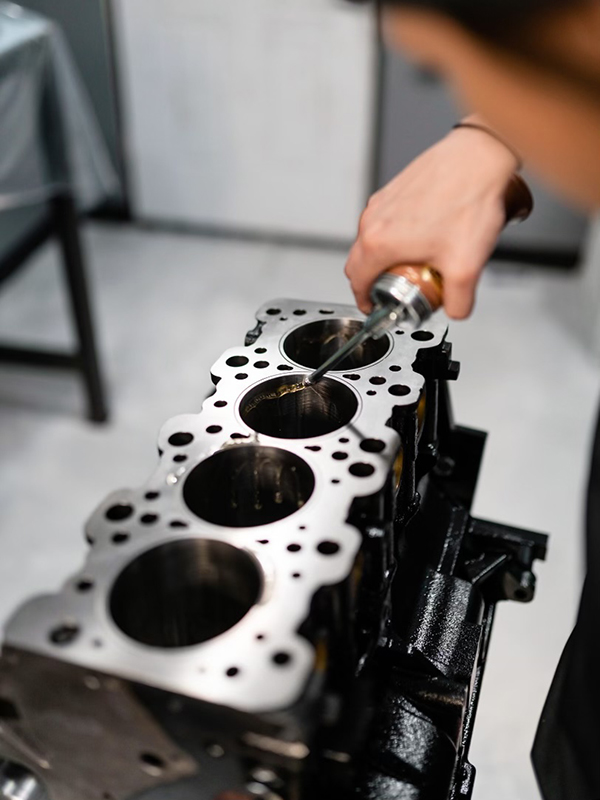

The shop has five full-time employees. Nicole is the one primarily doing engine blueprinting and assembling, while Schiller is a jack of all trades within the shop.

“Nicole works her ass off six days a week and builds some impressive engines,” Schiller says. “She’s got the good job in the engine room. I’ll do final assembly on an engine such as putting the valve cover on, timing the engine and stuff like that after Nicole is done with it. I’ll also install engines in the cars. I’ll also help the guys out with whatever needs to be done, ordering parts, posting on social media, stuff like that.”

The shop also has use of an engine dyno as iCraveBoost Performance lends space to Steve Sampier and his company, Divulge Motorsports.

“Steve moved his dyno into our shop and provides in-house calibrations,” he says. “He does all the tuning and stuff like that. He’s got a really nice beard, so we call him the beard of knowledge. We’re two separate entities, but he’s like the subcontractor who keeps his dyno at our shop.”

iCraveBoost currently sends out its machine work to Arlington Machine in California, but future plans include adding a Rottler or Haas CNC to bring that work in-house. For now, the engine shop is capable of building custom turbo manifolds, downpipes, full exhausts, intercooler piping kits, and offers customers tuning, servicing, install, engine building, and fabrication all under one roof.

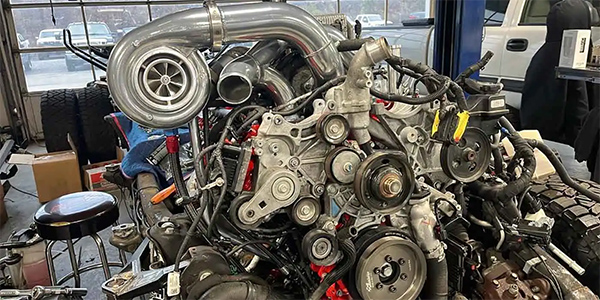

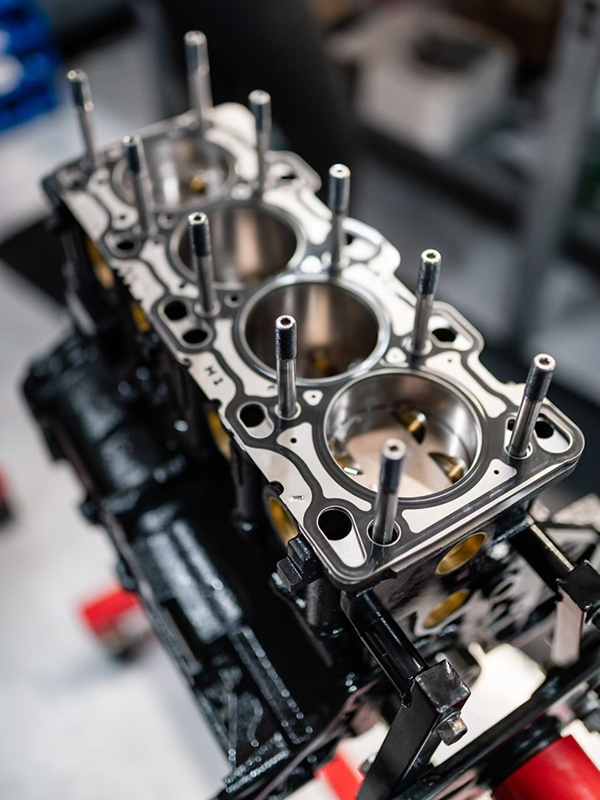

One example of the shop’s engine prowess is Nicole and Schiller’s own Evo engine build – a turbocharged 2.0L 4G63.

“It has a billet crankshaft, which is an 88mm stroke,” he says. “It has H-beam connecting rods with 3/8ths rod bolts. It has our custom-spec Wiseco pistons. All the machine work was done by Aaron at Arlington Machine. He takes the block apart and installs new freeze plugs, cleans the oil galleys, makes sure the block doesn’t have any cracks in it and all that good stuff.

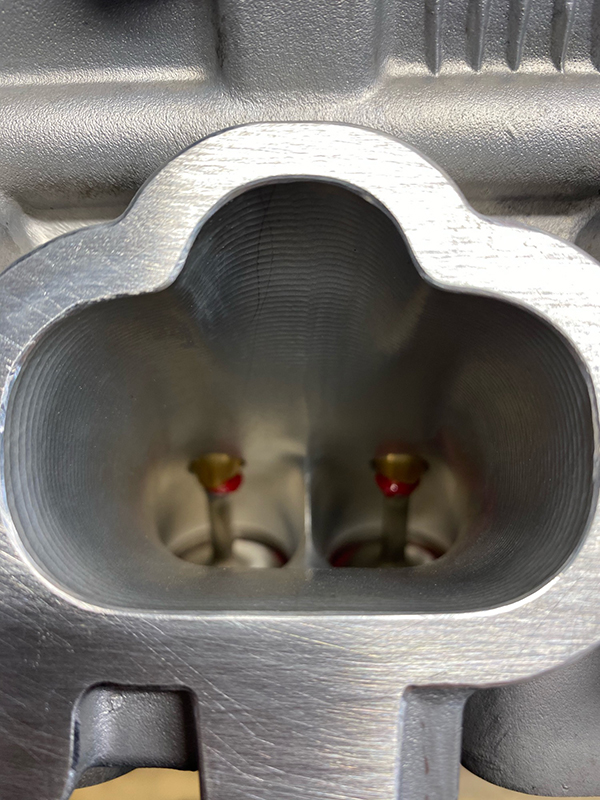

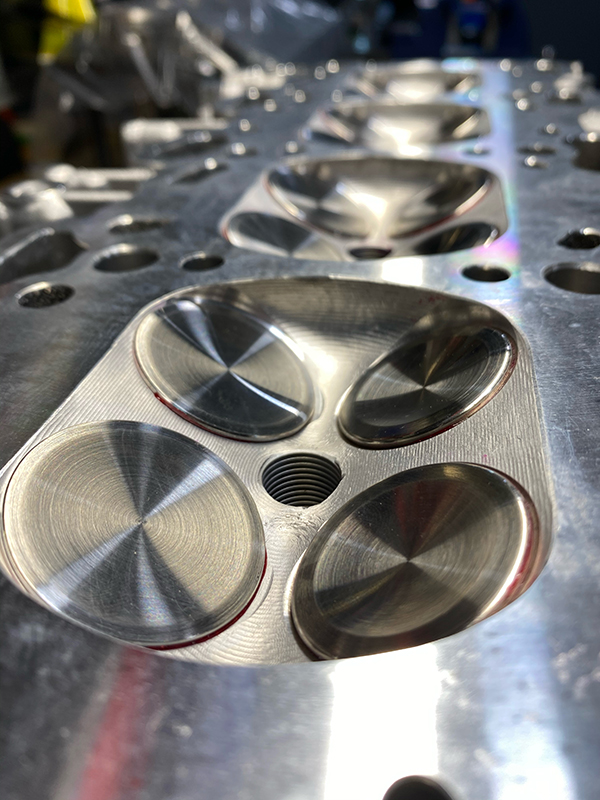

“The engine has an Arlington spec ported head with Kelford TX 280R camshafts. It has Kelford valve springs and retainers and GSC super alloy valves. It has a Kiggly trigger plate for ignition timing pickup and ARP 625 head studs. It’s also an o-ringed block for higher boost levels. We’ll be running a Xona Rotor 105 69S turbo, which will flow through one of our in-house made exhaust manifolds.”

The engine is going in the shop’s Evo IX, which is a street/strip car. It will have a dog engagement transmission, so it’ll have a Liberty Gears dog box in it. It’ll also have an Aeromotive 15-gallon fuel cell with a brushless fuel pump and four Injector Dynamics 2,600cc injectors.

“It’ll have one of our ignition coil kits on it with a MSD Pro 14 ignition box, a Custom Plenum Creations carbon intake manifold, our custom iCraveBoost titanium 3-inch intercooler piping kit, and a slim radiator with a built-in fan shroud,” Schiller says.

The engine also has a standalone bLink engine management system and the Murphy’s say it will likely also get a 50-shot of nitrous.

“The goal is just to have a nice, fun street car that can go to the events and rep the shop and hurt some Viper’s feelings,” he says.

With a potential output of 1,100 horsepower, it should achieve those goals and then some.

Engine of the Week is sponsored by PennGrade Motor Oil, Elring – Das Original and Scat Crankshafts.