Article courtesy ImportCar.

An electric parking brake is a standard feature on many Mercedes-Benz, BMW and AUDI/VW platforms. Using an electric motor to apply the parking brake eliminates mechanical linkages and levers in the passenger compartment.

On many European models, the electric motor applies the shoes in the drum hat or the rear pads in a caliper’s parking mechanism. The system operates and applies the parking brake without the knowledge or permission of the driver. When a vehicle is parked, it will engage the parking brake. This is done for safety, but it also stops the vehicle from rolling until the parking pawl engages.

Configuration

An electric parking brake can come in two configurations. Both actuate conventional parking brake mechanisms in the hat or on the caliper. Both systems share sensors and basic controls.

The first is a cable-actuated system. The second is a motor mounted to the body of the caliper. Most early systems in the early 2000s were cable-actuated systems.

The system has an electric motor connected to a cable the pulls on the equalizer bar. Some cable systems for BMWs have separate cables for each rear wheel.

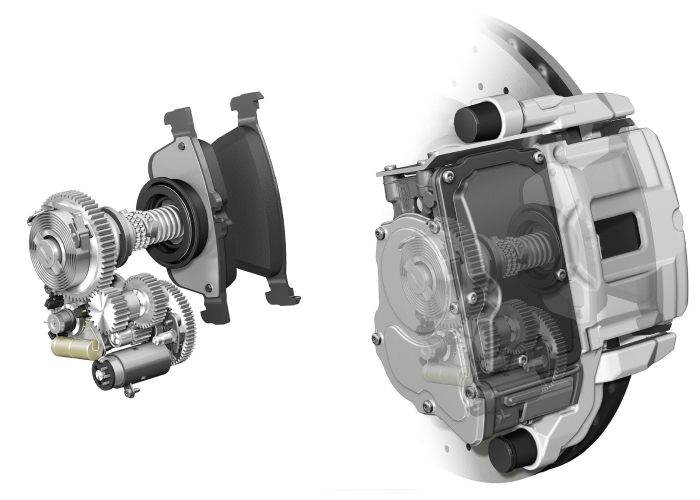

When the parking brake actuator is activated, the actuator retracts the cables attached to the caliper or the shoe mechanism. The actuator is made up of a gear train that rotates a splined screw nut to retract the cable.

What is important to understand are the sensors inside the motor assembly. The first sensor measures the number of turns of the motor or position of the screw. The second sensor measures the amount of current the motor is drawing to engage or disengage the parking brake. These two sensors help to spot problems with the operation of the motor, so the system does not fail with the parking brakes engaged or only one caliper engaged.

Some systems use motors and gears attached to the back of the caliper. Like the cable pull system, it uses sensors to measure the number of turns and the amount of current used by the motor.

Controls

The biggest difference between BMW, AUDI and Mercedes-Benz systems is where the “smarts” for each system are located. Most cable pull systems use a control module that is part of the housing with the motor. Caliper-mounted systems will have a module mounted in the trunk with wiring going to the calipers.

Most module will communicate with the ABS or stability control system. Some early systems were controlled by the body control module. Some newer systems will communicate with the button assembly that is a module. Always look at the wiring diagram to see which modules and systems the parking brake module is connected to on the vehicle.

The important diagnostic concept to remember is that when the button is pushed by the driver, it is looking at many pieces of data. The position of the brake pedal, vehicle speed and gear position matter if the final command being carried out. All of this information is shared between modules instead of each module having a sensor.

If there is an issue with the ABS module missing a wheel speed input or the module is having a communication problem, the parking park will go into a fault mode and not engage the parking brake. A good scan tool that can communicate with the parking brake system can make a diagnosis faster. These systems have codes and can be bi-directionally controlled.

Service Mode and Calibration

To replace the rear brake pads on a vehicle with an electric parking brake, it is easy to retract the pistons. All that is needed is a scan tool or navigating the menu in the instrument cluster or infotainment screen to put the parking brake into service mode. For some platforms, however, a scan tool is required to calibrate the piston’s position after the new pads are installed.

Do not try to reverse polarity or force a piston back. You could damage the gears or motor. It is possible to release the system if the battery is dead and the trunk can’t be opened. Look in the service information – don’t improvise. Some of these procedures are outlined in the owner’s manual that is in the glove box.