Ford’s 3.5L EcoBoost engines have proven to be a solid power unit, but many of these engines are out of warranty and are bound for service. Here are the 6 failures and what to look for.

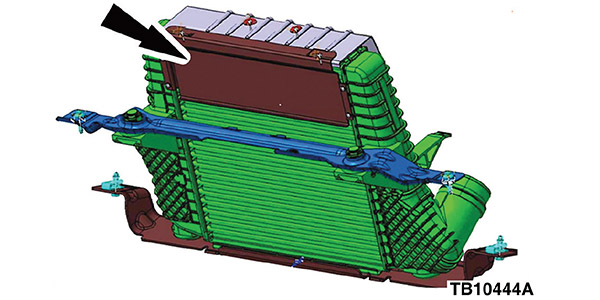

1. Condensation in the Intercooler

Some 2011-2012 F-150 models equipped with a 3.5L EcoBoost V6 engine may exhibit an intermittent stumble and/or misfire on hard acceleration after an extended drive at highway speeds during high humidity or damp conditions. This driveability concern was due condensation trapped in the intercooler.

Ford’s solution was to remove the air deflector from the top of the Intercooler and install it on the bottom to help vaporize the condensation trapped at the bottom of the intercooler.

Before you reposition the air deflector, you need to confirm the misfire condition was due to the condensation. The freeze frame data for the misfire should indicate the engine was above 2500 rpm with a 100% load. Also, Ford updated some models with a new intercooler to prevent this problem. The full details can be found in TSB 13-8-1. Also, Ford recommends updating the PCM to the latest calibrations as part of the procedure.

One solution that can be found online is to drill a 1/16” hole in the bottom of the intercooler to drain the condensation and even oil. This procedure can create a leak in the system.

2. Fresh Calibrations

There have been at least nine updates to change calibrations and operation software for the 2011 models with the 3.5 EcoBoost to address problems with the vacuum, ignition and shifting. If you get a customer in your shop complaining of a loss of power or stalling, check the PCM to make sure it has the latest calibration. TSB 13-8-10 covers 2011-2013 models with the 3.5L V6 and discusses how new calibrations can resolve a buck/jerk at steady cruise conditions with the transmission in sixth and lugging up grades at 1500-2000 RPM.

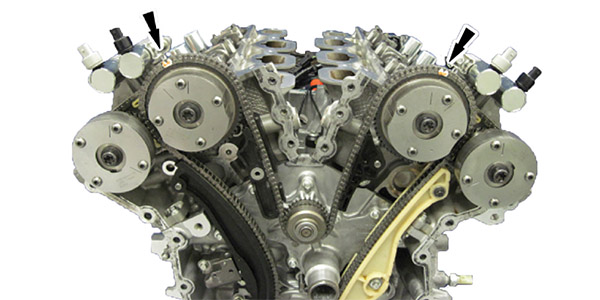

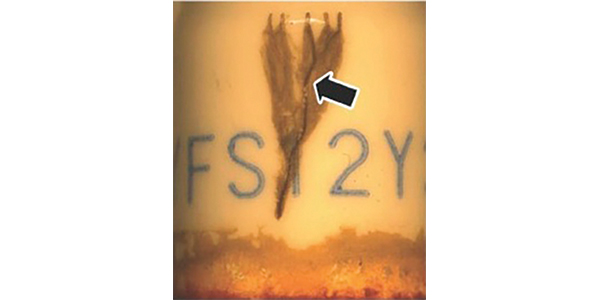

3. Timing Chain Wear

Since the 3.5L EcoBoost is turbocharged, the oil is under extreme stress. If the driver pushes it past the recommended oil change interval, the first item to show the abuse is usually the timing chain. Worn-out oil can damage the chain, guides and tensioner. When the chain is worn and stretched, the PCM detects the changes in camshaft position and sets code P0016 for crankshaft/camshaft correlation. Check out TSB 14-0194 for more information.

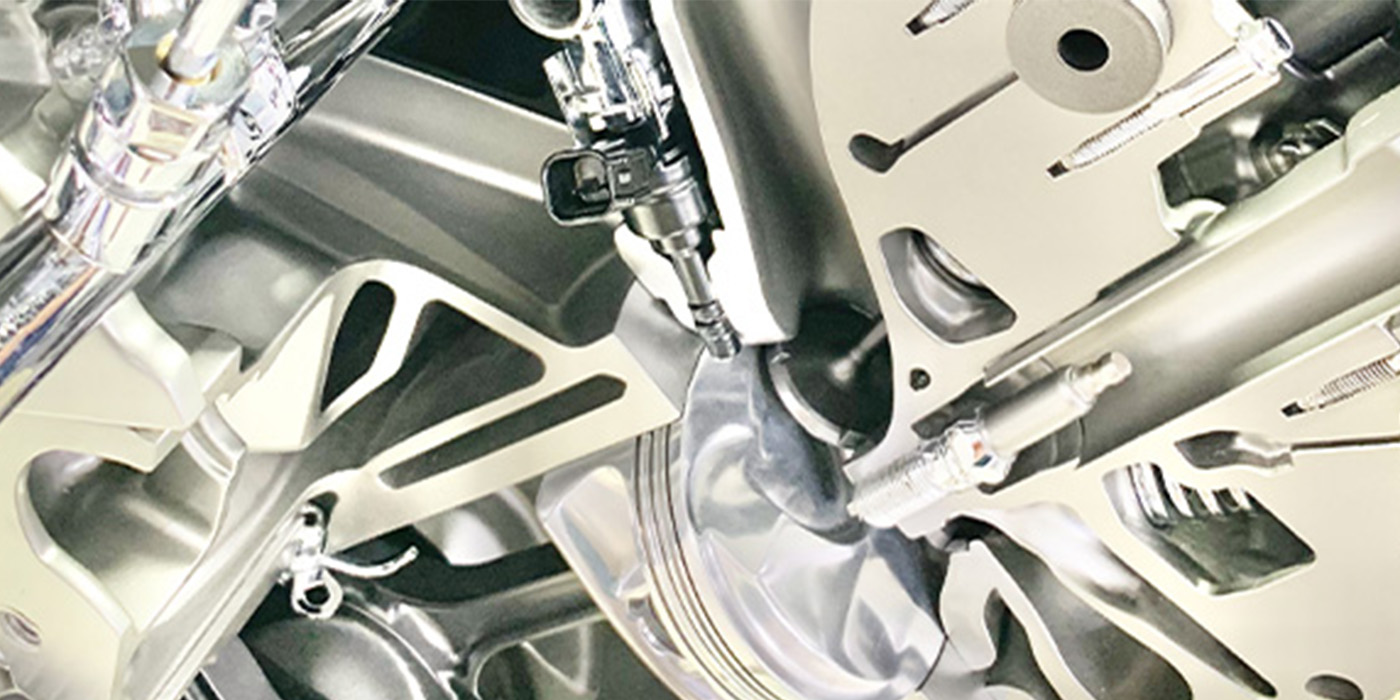

4. Ignition Issues

If you get a 3.5L EcoBoost in your shop with misfire code(s) P0300-0306, pull the plugs and coil boots and look for carbon tracks on the insulator of the plugs. If any tracking is present, replace all the plugs and boots. See TSB 14-0180 for more information.

5. Induction Cleaning Mistakes

The 3.5L has not had many issues with carbon build-up on the intake valves. But some DIY owners will use induction cleaners that are injected into the intake. These types of cleaners can damage the turbochargers’ bearings, seals and turbines. The best advice is to use high-quality fuel. Also, Ford has released new PCV parts and PCM calibrations to reduce the amount crankcase vapor ingested into the intake. See TSB 15-0003 for more information.

6. Blue or White Smoke from Exhaust

Some 2013-2015 models equipped with a 3.5L Ecoboost (not the F-150), the engine may exhibit blue or white smoke from the exhaust while driving after extended idle. The problem is the positive crankcase ventilation (PCV) hose valve cover adapter. Disconnect the PCV hose to valve cover adapter’s quick connect fitting from the valve cover adapter. When the valve cover adapter is removed, damage will occur to the adapter locking mechanism. Make sure detached pieces of the valve cover locking mechanism do not fall into the open valve cover port during removal. Rotate the adapter counterclockwise and remove from valve cover. Ford has issued redesigned valve cover adapter (P/N HL2Z-6762-A) to seal the leak.