Models

2013-2017 Explorer and Police Interceptor Utility Vehicles that are registered or sold in high corrosion states.

Condition

Some of the affected vehicles, sold or operated in certain traditional corrosion areas, have experienced fracture of the outboard section of the rear suspension toe link after completion of a prior recall repair. Preliminary assessment of field data indicates that the toe link ball joint (built into the knuckle) may be susceptible to seizing in certain high corrosion areas. A seized toe link ball joint can increase bending stresses in the toe link outboard of the turnbuckle. Rear toe link fracture while driving could result in unusual vehicle handling characteristics, or difficulty controlling the vehicle and may increase the risk of a crash.

Correction

Check both toe link ball joints’ integrity and, if necessary, replace the rear wheel knuckle(s), and adjust rear toe. This service must be performed on all affected vehicles at no charge to the vehicle owner.

- Lift the vehicle. Remove both rear wheels.

- Using a jack stand, support the rear suspension at ride height. Disconnect the toe link from the knuckle.

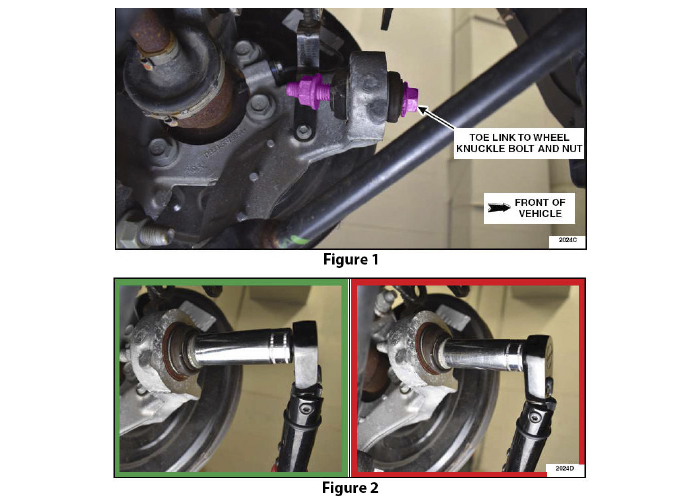

- Install the toe link to knuckle bolt and nut into the ball joint on the knuckle (Figure 1). Tighten the nut while holding the bolt still with a wrench, torque it to 111 Ft/lbs.

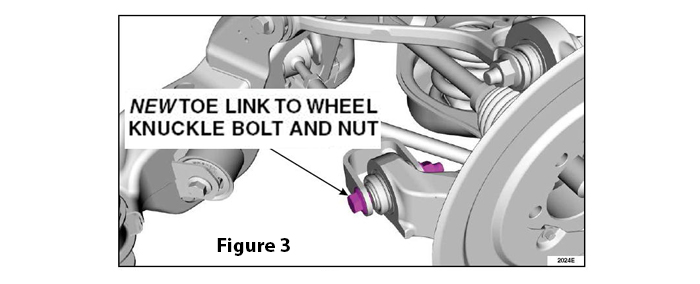

- Using a torque wrench, rotate the toe link to wheel knuckle bolt while keeping the ball joint straight. Do not allow the ball joint to twist (Figure 2). Note the reading on the torque wrench when the ball joint begins to rotate.

- Repeat steps 2 through 4 on the other side of the vehicle.

- Are the readings over 11 Ft-lbs?

a. If YES, the RH ball joint has FAILED.

- Remove and discard the toe link.

- Replace the knuckle.

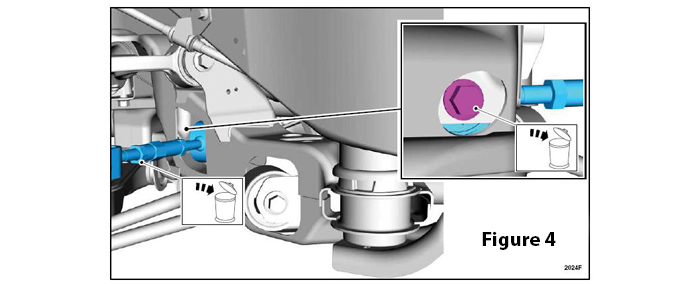

- Replace the toe link with new bolts (Figure 3 & Figure 4).

- Perform an alignment.

b. If NO:

- Replace the toe link to wheel knuckle bolt (Figure 3).

- Install the toe link to the knuckle with the vehicle suspension at ride height.

- Torque the nut to 111 Ft-lbs.

- Perform an alignment.