Article courtesy BRAKE & FRONT END.

When replacing the rear rotors or pads on GM models with an electronic parking brake, it might be necessary to disengage the parking brake during the job. The preferred method is with a scan tool. But, it can be performed using the following procedure:

- Block the drive wheels.

- Turn the ignition switch to the ON/RUN position with the engine off.

- Place the automatic transmission in PARK or manual transmission in NEUTRAL, as equipped.

- Apply and hold the brake pedal. The brake pedal must remain applied throughout the parking brake cable tension release process.

- Press and hold down the electronic park brake (EPB) switch for approximately 5 seconds.

- Observe the PARK BRAKE lamp on the instrument cluster.

- When the PARK BRAKE lamp flashes, release, then immediately press and release the EPB switch. The parking brake cable tension is fully released.

- Release the brake pedal.

Parking Brake

Most 2014 and newer GM vehicles are optioned with either a manual or electric parking brake that utilizes a drum-in-hat arrangement. To adjust the manual system, lock the pedal in the full-release position and adjust the cable using the correct procedure listed in the service information. In some cases, the shoes will need to be adjusted to fit the rotor.

Vehicles with an electronic parking brake have a switch in the center console, which takes the place of the manual parking brake system (the foot pedal and release handle). In case of insufficient electrical power, the electronic parking brake can be neither applied nor released.

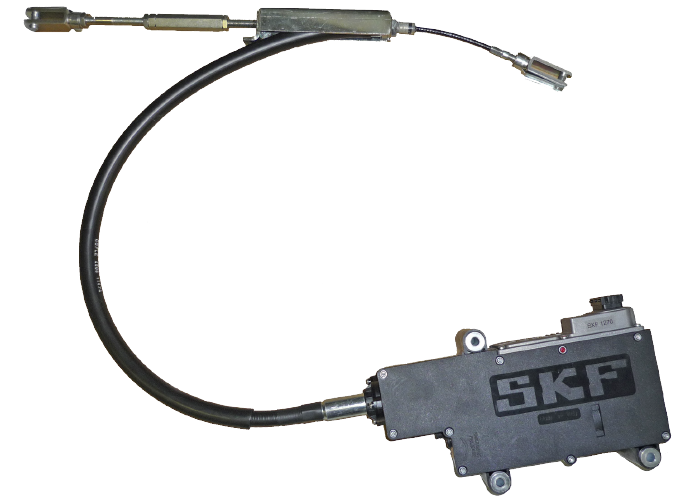

The parking brake control module has an internal motor, apply actuator, release actuator and temperature sensor. The parking brake control module also contains the logic for applying and releasing the parking brake when commanded by the EPB control switch. When the parking brake control module receives a signal from the switch, the internal circuit board temperature is checked to verify it is within operating range before the control module performs the requested operation.

The EPB module receives hard-wired signals from the apply/release switch. The module receives wheel speed sensor signals, engine torque, gear information, and brake pedal signals through the GM-LAN. The system can be calibrated using a factory or enhanced scan tool. If you do not have a scan tool, you can use the following procedure to adjust the module:

- With the ignition ON, apply and hold the brake pedal.

- Push and hold the EPB switch down for 5-6 seconds.

- Release the EPB switch.

- Momentarily push the EPB switch down.

- Remove the EPB MODULE fuse and reinstall.

- Apply the EPB.

- Release the EPB.