When a vehicle’s tire gets damaged, it’s often more cost-effective for the customer if you repair it instead of selling them a new tire. But, cost isn’t the only concern. The more important question is: Is safely fixing the tire possible?

Start by making sure the tire manufacturer authorizes the proposed repairs for the particular tire in front of you. Failure to do so may cause catastrophic failure of the tire during inflation or use.

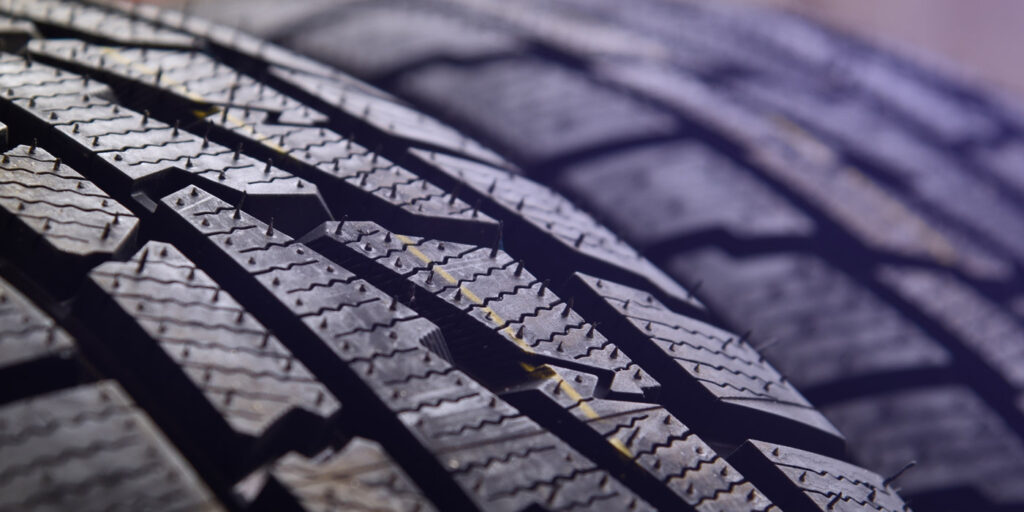

Next, take a look at the tire itself. Check for the following indications that a tire should be replaced, not repaired.

Do not repair the tire if:

- There is 2/32-in. or less of tread on any two adjacent tread grooves. If so, the tire is not legal for use on U.S. highways.

- The tire cord or steel belt is exposed.

- There are flex breaks or severe sidewall abrasions.

- There is any evidence of a separation in the tread area or the sidewall.

- There is any evidence to indicate the tire has been run flat.

- There are punctures or damage to the shoulder or sidewall areas.

- Areas of the bead that are integral to the structure of the bead area are damaged.

- The tire does not contain a serial number.

Remember, never inflate a damaged tire, as this could result in serious injury. If a tire appears to be damaged, dismount it and thoroughly inspect it.

This Tech Tip is courtesy of BendPak