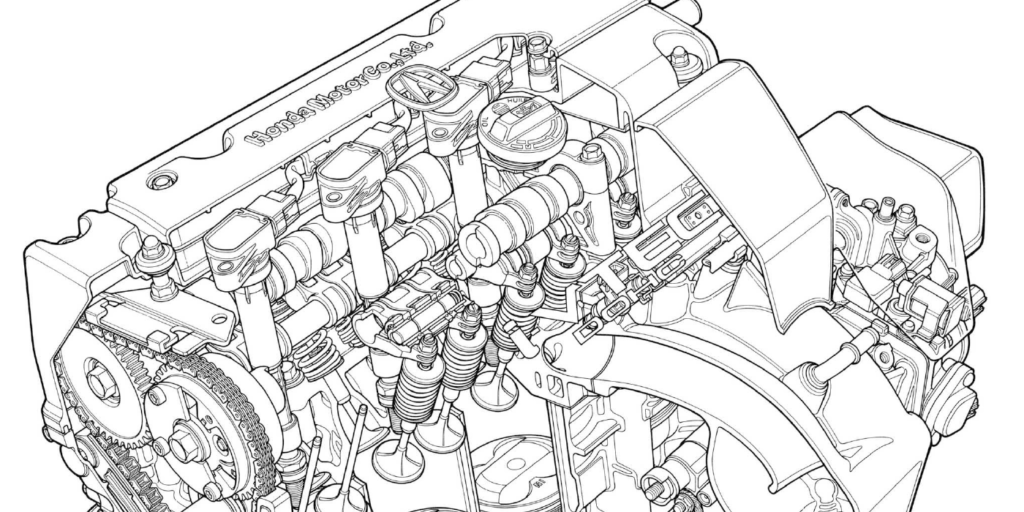

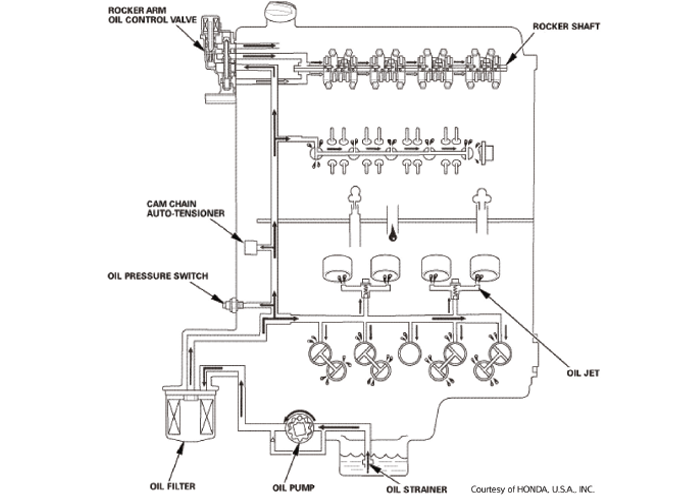

Just about every engine lubrication system, including Honda’s, operates the same in theory. An oil pump generates the pressure, oil is sent to oil galleys, and then flows back into the pan. In practice, however, it is much more complicated. An oil system practically manages a controlled leak into the oil pan.

The leading cause of low oil pressure-related complaints with Honda vehicles is the oil level. If the oil level is low, the oil pickup can become uncovered and suck in air. The level of oil is often related to an oil consumption problem. These issues include leaking valve seals and piston ring problems. The other issue is the customer not checking their oil level regularly.

Oil Pumps

An oil pump generates more pressure and volume than required. The excess volume and pressure are bled off with a relief valve back into the oil pan. Old oil pumps are usually worn, with sloppy internal clearances and reduced output. Wear between the gears and the housing provide leak paths that can hinder a pump’s ability to generate normal volume and pressure. While oil pump failure for Honda inline-four and 3.5L V6 engines is rare, it has happened on some high-mileage Honda engines.

The oil pump should be the first point of inspection and diagnosis. Honda typically positions its oil pressure sensor between the bottom end of the engine and the camshafts.

The pressure output can be checked using the data PIDs for oil pressure. The information on some engines will not be in pressure on a scan tool; these engines just have a switch that closes when enough oil pressure is generated while cranking.

Using an external oil pressure gauge is the only way to determine if the oil pump is healthy. At idle, the pressure should be around 10 psi. At 3,000 rpm, the pressure should be approximately 70 psi for the 3.5L V6. For four-cylinder engines, the pressure specification at 3,000 rpm can vary between 35 to 65 psi, depending on the displacement and model year.

Oil Filter

The oil filter on Honda engines is known as a full-flow filter and is positioned after the oil pump. On most Honda automotive applications it is a spin-on canister filter. Inside the filter is a bypass valve that allows the oil to pass around the filter media if it is clogged. The filter also has an anti-drainback valve to prevent the oil from siphoning back into the oil pan when the engine is not running.

If the filter is in bypass mode, the oil will not be filtered. This can damage the engine and cause clogging of the strainers for the variable valve timing system.

If the anti-drainback valve fails, it could delay oil getting to the engine’s top end and the camshaft actuators and oil control valve when the engine is started. This can cause noise from the lifters and actuator when the engine is first started.

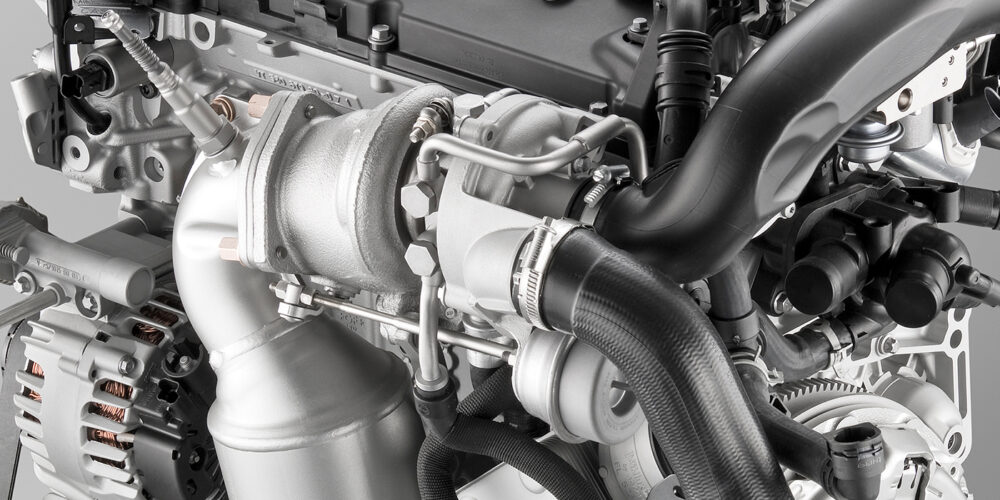

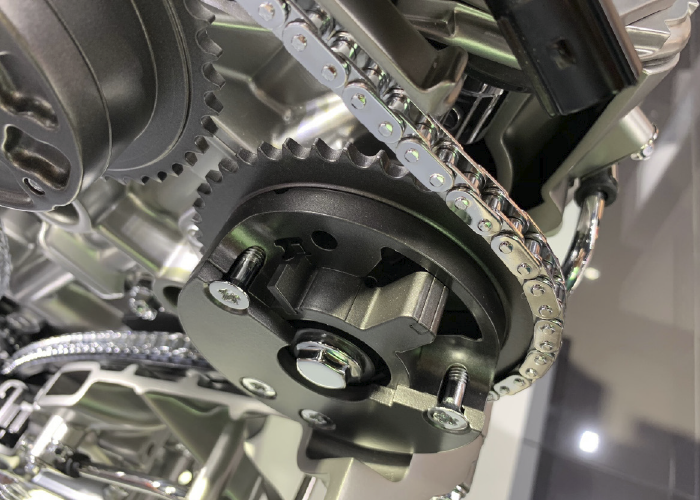

Chain Tensioners

The Honda 3.5L V6 uses a chain to turn the oil pump. It has a tensioner that is powered by oil pressure. The four-cylinder engine uses an oil-powered tensioner for the timing chain. If the tensioner leaks, or if the pressure is too low, the chains can cause noise.

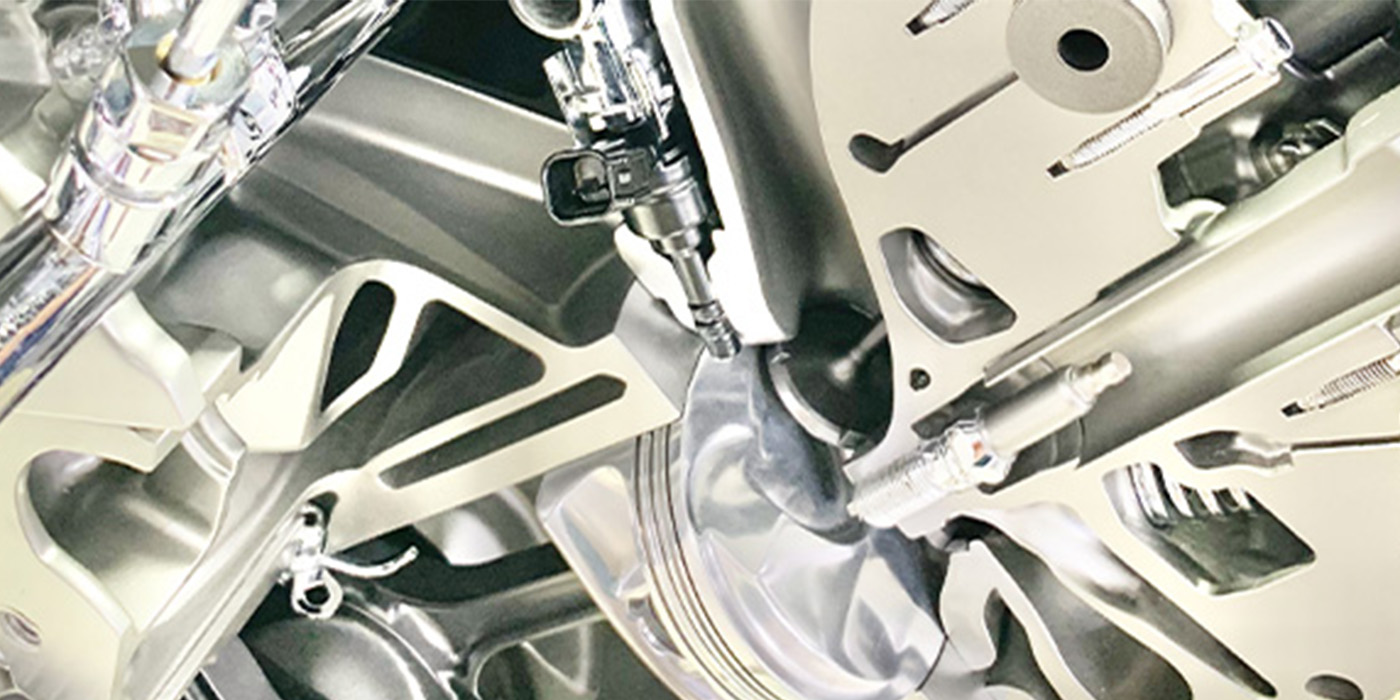

Bottom End

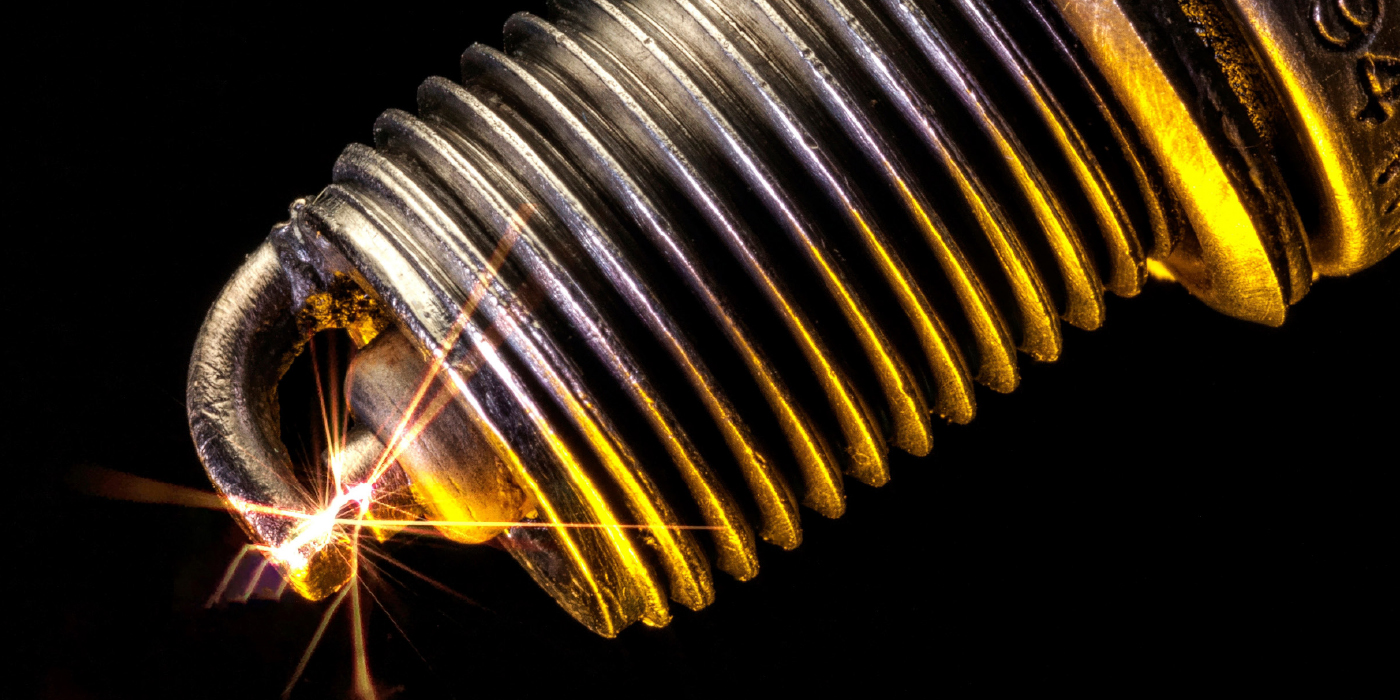

Like all engines, oil is used to lubricate the bearings and connecting rods. Oil is also used to cool the pistons. Jets are positioned at the bottom of the cylinder. The jets shoot oil on the backside of the piston. The oil helps to remove heat from the piston and lubricate the cylinder walls. If the oil jets become clogged, it can cause hot spots on the face of the piston. This can cause detonation, pre-ignition and carbon buildup on the piston.

If the bottom end of the engine is not getting enough oil pressure, it is easy to diagnose by the knocking of the connecting rods.

Top End

Oil is pumped to the head, and it supplies oil to the rocker shafts, camshafts and variable valve timing system.

On late-model Honda engines with direct- injection engines, oil will be pumped to the lobe that powers the high-pressure fuel pump. If the oil is not lubricating the lobe and follower, it can damage the camshaft and lower the amount of pressure the pump can generate.

Honda uses oil pressure-powered actuators to move the camshaft(s) for the variable valve timing system. Oil pressure is supplied to an oil control solenoid that controls the movement of the camshaft.

Since the engine management system can’t measure pressure provided to the oil control solenoid, it looks at the position of the oil control solenoid and the actuators’ movement to decide if enough oil pressure is reaching the variable valve timing system. If the oil control solenoid movement does not cause the desired camshaft position, the engine control module will set a code.

The most common code is DTC P1009 for the camshaft stuck in the full advanced position. P1009 is caused if the oil control solenoid is not being supplied with enough oil pressure. The camshaft is advanced because there is not enough pressure to resist the force of the camshaft’s lobes pushing down on the valves.

The oil control valve has a strainer that filters the oil. The mesh filter can catch large particles in the oil before they can reach a solenoid or actuator. The strainer can be serviced or replaced.

On the side of the oil control solenoid is another screen that can catch large pieces of debris if the strainer fails.

When trying to resolve a probable low oil pressure condition on a Honda engine, stick to the basics first. The first check is with the dipstick. Next, look at the oil. A Honda owner will often use the wrong oil viscosity when topping off at a gas station. Once those bases are covered, start moving up from the pump to the variable valve timing system.