Tomorrow’s Technician and B’laster are searching for automotive technology instructors who think outside of the toolbox with the first-ever “B’laster Instructor of the Year” program. Each month, we will share an automotive instructor’s story who is in the running to be named the B’laster Instructor of the Year winner in May 2019. Instructors can enter the B’laster Instructor of the Year program at TomorrowsTechnician.com/instructor-of-the-year.

Our second finalist shares how with a “can-do” attitude, he’s created an unofficial engine and collision repair program at his school. Jonathan Couch has both AERA Certifications and is an ACA/ASE World Class technician, owner of Couch’s Automotive Racing Services (C.A.R.S) and has been an automotive instructor for the past 7 years. He has taught at Klein Forest High School since fall 2016. Couch got his start working at a Toyota dealership right out of high school and later attended San Jacinto College while working at O’Reilly Auto Parts. He spent 3 years working at San Jacinto College, where he earned an associate’s degree, and later earned his bachelor’s degree in Automotive Technology at Sam Houston State University in December 2013. In 2013 he worked for Lone Star College. Couch is only four ASE Certifications away from being one of six people to have all of the available ASE Certifications.

Words by Jonathan Couch

No and can’t are some of my least favorite words. Students will often ask a question like, “Can you teach me how to pull a dent?” or “Can you teach me how to weld?” A lot of instructors would answer “No,” or “We can’t because it’s not part of the class.” I’m not that instructor.

While Klein Forest High School doesn’t offer collision repair, diesel or engine machining officially, we often venture off into those areas alongside the norms of a typical automotive technology program.

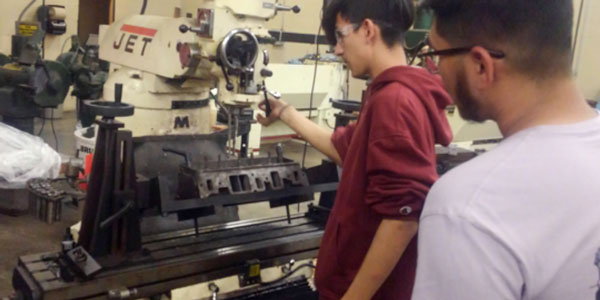

I found a passion for engine building years ago and with my experience in the shop and teaching engine repair, I’ve been able to bring an unofficial engine machining program to Klein Forest High School.

During the 2017-18 school year, we built several engines. One had cylinder heads that were severely cracked. I used this as a teaching opportunity and taught a student how to repair cracks in cast iron heads using tapered pins. I also taught the students how to grind valves and perform a 3-angle valve job.

I also bought a rollover fixture for the vertical mill in manufacturing so we can replace integral valve guides and perform other machining operations on cylinder heads in the future. I’ll often bring some of my engine machining tools to school to demonstrate or teach.

This past year I taught my students how to bore integral valve seats and install a valve seat insert using some of my personal tooling and a hand drill. All trades find themselves on a car, so by proxy, mastering the trade of automotive technology makes you a master of many trades. It doesn’t matter to me if the students are building bird houses, welding pipe, spraying paint, or building engines. I want to see students learning to perform a trade, and if their passion is something typically outside the scope of automotive technology, then I accommodate them as best I can. I can assure you there was a lot of PB B’laster used when dealing with some of those broken bolt extractions.

The summer of 2017 we agreed to participate in an art car project with our art department where we built our own spray booth and performed body repairs on the vehicle using a stud welder and other means of straightening sheet metal. This was a joint project between the Auto Tech and National Art Honor Society (NAHS) clubs at Klein Forest High School.

When the art department came to me and said “Can we do an art car project together?” (knowing that it involved doing body work), I said absolutely. I brought all my body shop tools from home and even brought in a friend, Chuck Greenwell, as a guest speaker/trainer to help me get the students up to speed.

For the art car project, we used a 1993 Dodge Caravan that had been sitting in someone’s driveway for years. It was in admittedly bad shape and was donated to us in spring 2017. We towed it to school and began work. At the time, it was the only training vehicle I had. So, when the art department asked if we could do the art car project it was the only choice.

We began by sanding the dents down to bare metal to be filled or pulled and filled. We used a stud welder to start pulling dents while also using hammers, dollies and body filler to begin straightening some of the dents and dings in the body of the car. Students stripped out the interior of the car because it was in such bad shape and we just threw all of that away except the driver’s seat.

With lumber we borrowed from the construction department I framed up a spray booth and with the help of three of the art instructors we draped plastic sheeting over the frame to enclose the spray booth. We invested in hazmat suits and respirators for students to wear while in the booth. In just two days work we had the car sanded, dents mostly pulled, and the car primed for paint. This was a very impressive feat in so little time. None of this would have been possible without the help of Alexa Murland, Misty Crowe and Richard Cartaxo. These dedicated teachers suffered the blazing July heat in Houston to help supervise, coordinate, and assist in the project.

We have since had a new wing added to the school where they moved all of our CTE Department, and I unfortunately had to give that vehicle up for the sake of saving the two I have gotten since then that are in much better shape. To be fair to everyone involved and to best serve my students and colleagues,

I have substituted our first attempt with a 1992 Jeep Cherokee, which the sponsors of the NAHS club unanimously decided was a better pick moving forward. So, we’ll build a new booth and begin again with a new batch of students to teach.

My learning philosophy has always been a simple one. If you want to know how to do something then go do it, fail, do it again, fail and repeat until you succeed.

Enter today for the B’laster Instructor of the Year program at TomorrowsTechnician.com/instructor-of-the-year.